You know the five minute jobs I mean, the ones that take three hours and nearly set things on fire, like your hair, a pile of sawdust, solvent-based finishes, that sort of thing. Today was their day!

Started off with a quick job I’d been meaning to do for a while.

That panel saw is junk. Uncomfortable handle, not sharp, can’t be resharpened thanks to induction-hardened teeth…

Basically, a waste of shed space. Blade was kinked as well. One of Spear&Jackson’s lesser models, that. So, out with the angle grinder, hack through the rivets (because who uses screws when attaching plates to handles, that’s so passe and repairable…) and after a few minutes of standing in an actual light show and setting fire to the handle twice and almost catching my hair, a pile of sawdust and the box of finishes beside it….

You can’t really see it there, but there’s a fair amount of smoke and crap in the air there. And I’ve had to beat the everloving crap out of the pins holding the handle in place with a punch pin and a lump hammer. I am so not a fan of this saw.

So why not just dump it? Because it’s now raw material…

Out with the angle grinder, cut along some of those lines, nearly set fire to a few more things, and …

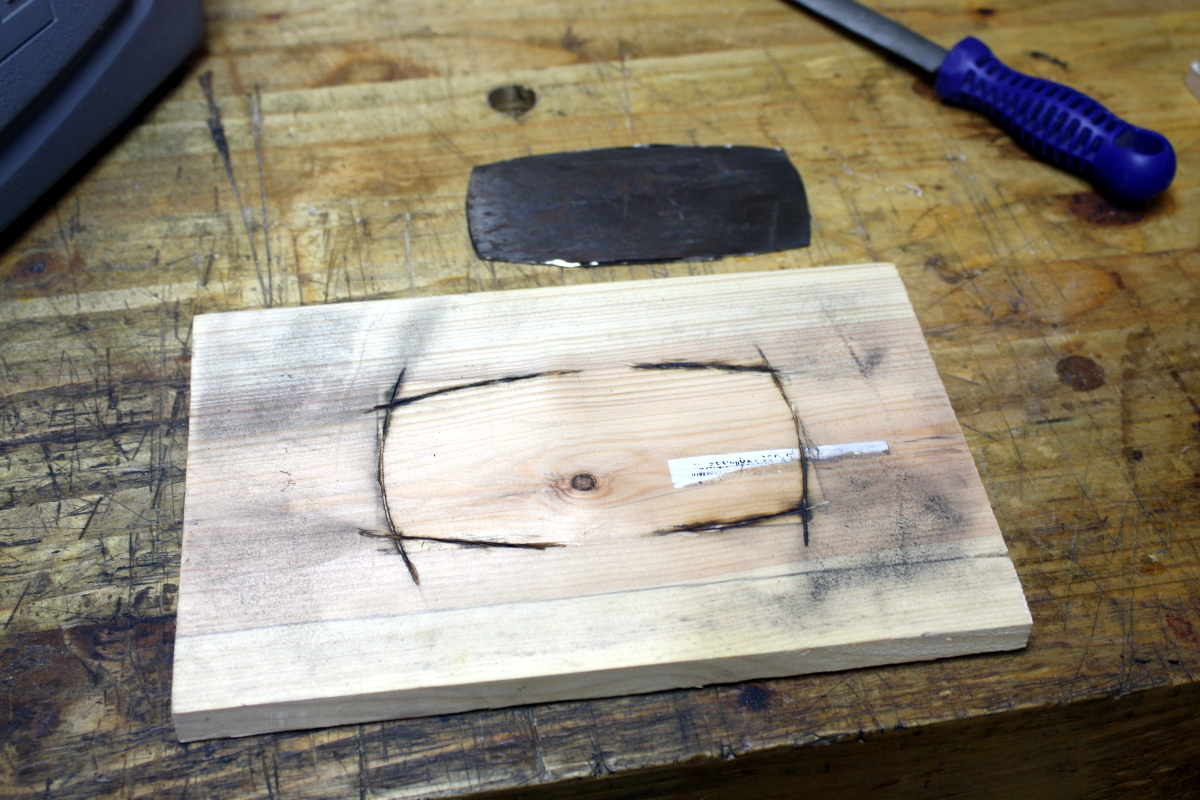

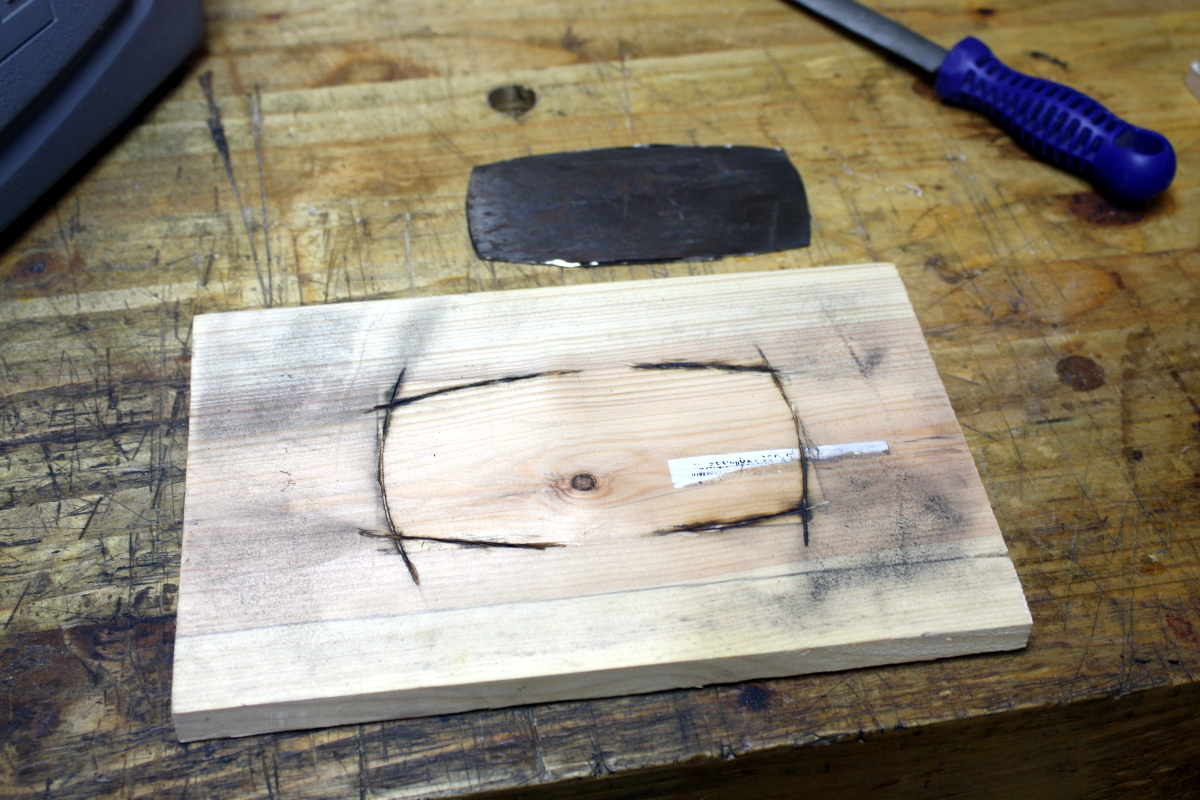

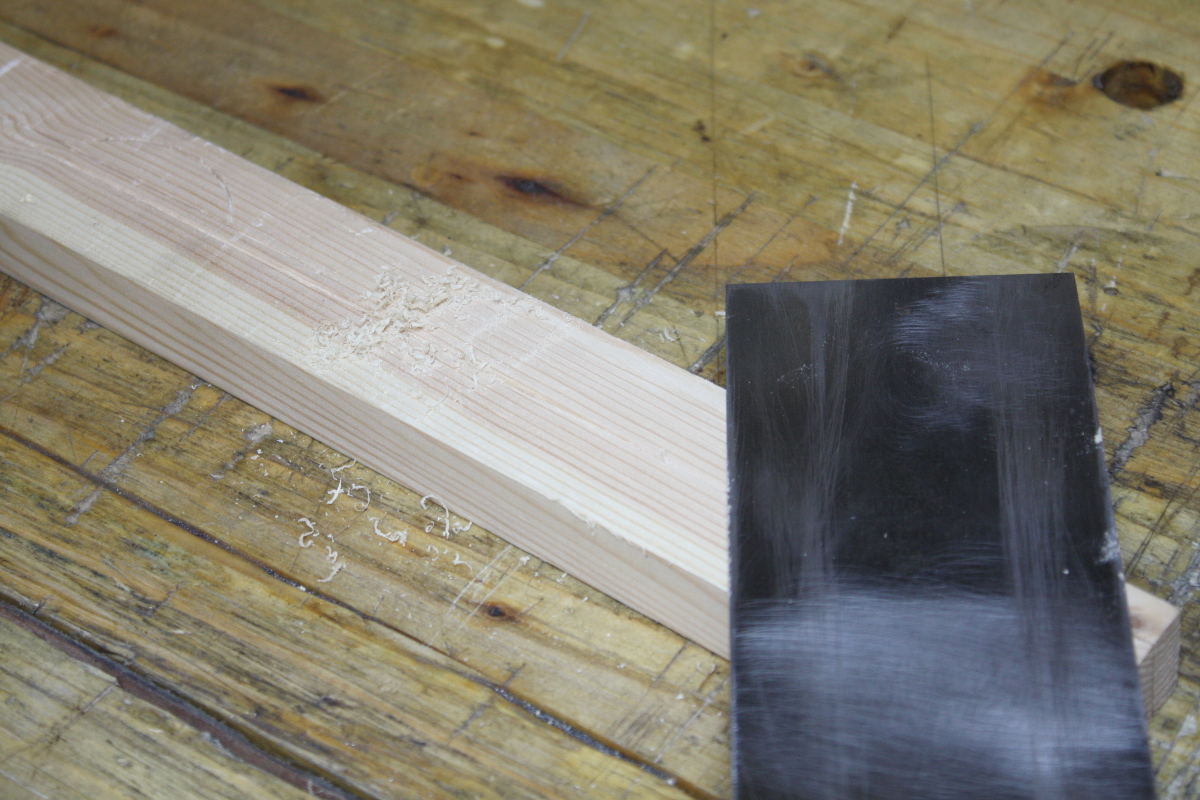

That’s a new card scraper and a chunk of stock for scratch stocks, which up to now I didn’t really have (there’s a blank or two in the lee valley scratch stock kit but that’s it and I’d rather be able to make some up as I need them).

The card scraper is the reason for doing this today. Chris Schwarz was talking about a different shape for a card scraper that he came across and it actually didn’t sound too weird so I thought I’d try it. Here’s the shape, nicked from Chris Williams:

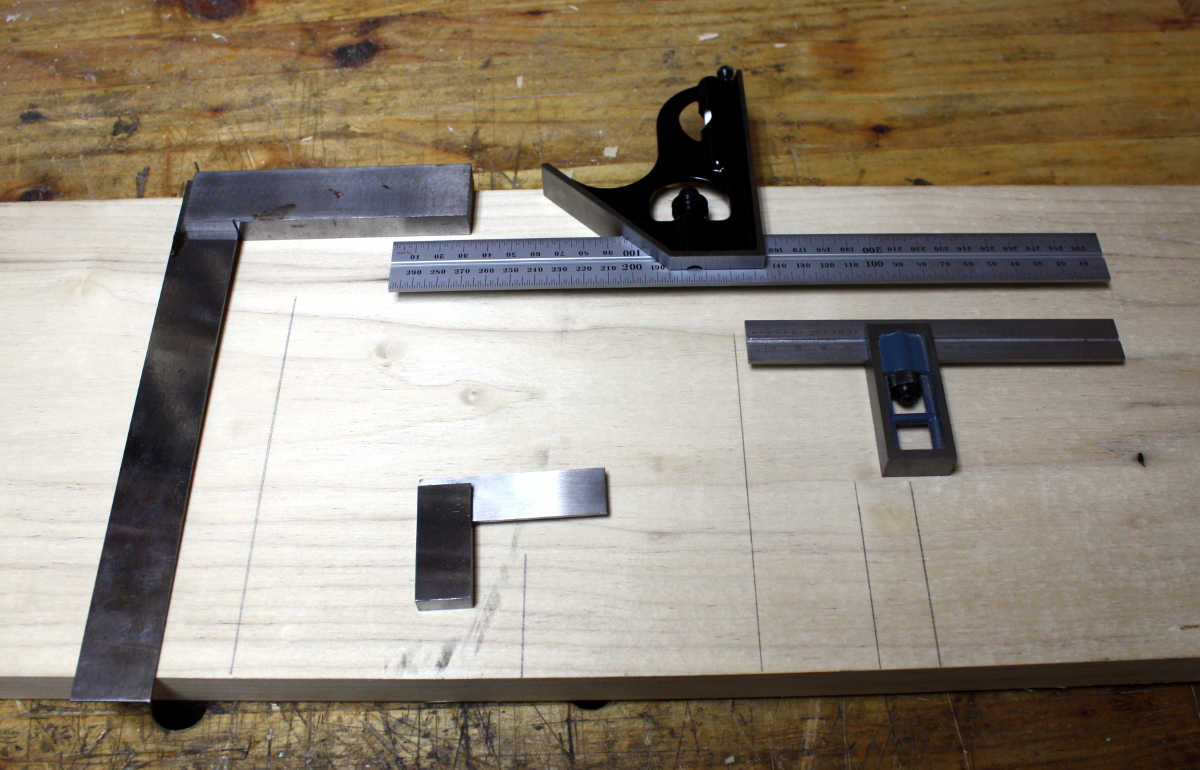

Rather than print it out and trace it onto the stock though, I figured I’d just be a smartarse and draw it from the likely origin.

Rather than print it out and trace it onto the stock though, I figured I’d just be a smartarse and draw it from the likely origin.

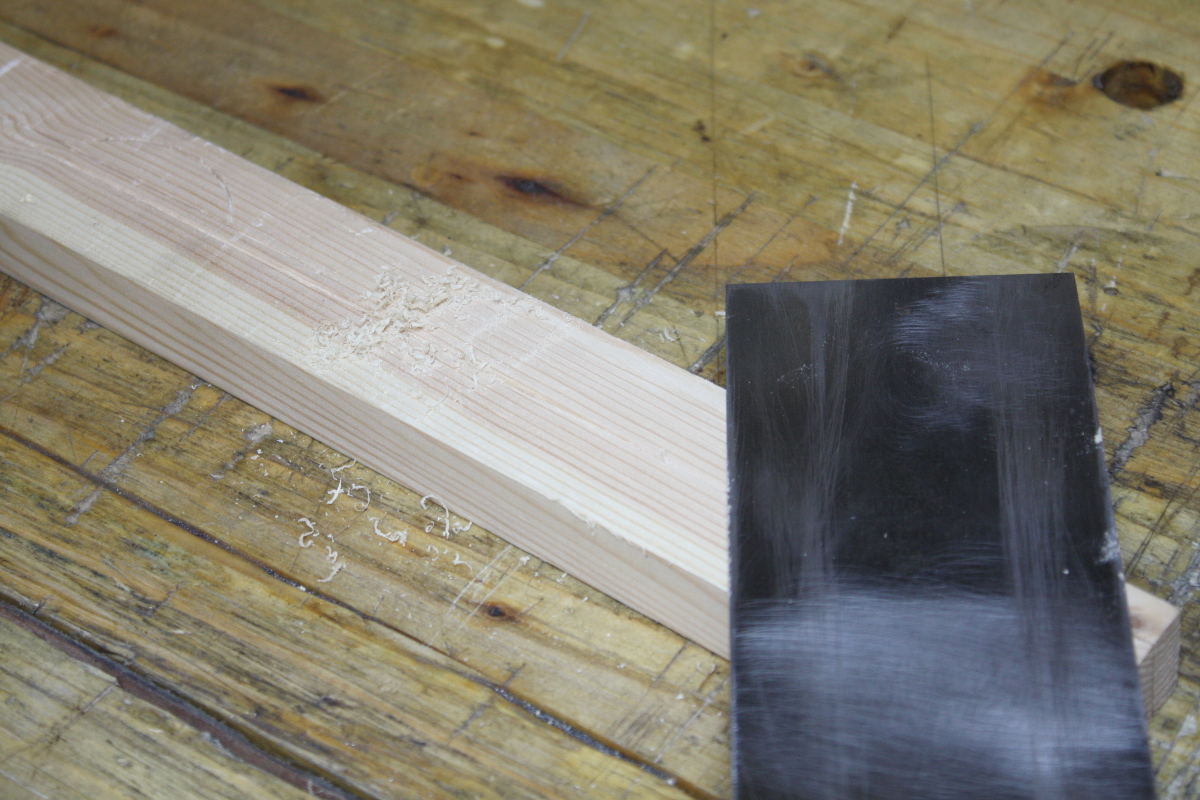

Now Chris (Schwartz) suggests you just grind away the excess metal, but we don’t all have 2×72 grinders and the like, so we make do…

Think of it as very fast artisanal filing.

Also you want a backing bit of scrap unless you’re better at this stuff than me, or have actual metalworking tools, or skills or whatever.

Because, you know, you don’t want to do that to your bench – whatever about the gouging, the spray of metal bits will ruin your next attempt at finishing…

Some deburring, some filing square, some time on the diamond plates and the strop and then the arno burnisher (which is kindof a cheat code to turning a hook on these things – I cannot get that to work with the usual screwdriver shaft/hardened steel anything/other metal burnishers, but the tungsten carbide on the arno does it every time). And then a quick test.

Control group’s fine as always…

New one acts like a plane with a nice camber – a lot more steerable, the steel in the saw blade was pretty good, and it might actually be a better scraper for scraping small areas in a targeted sort of way.

Then on to the next quick five minute job. The last one only took two hours…

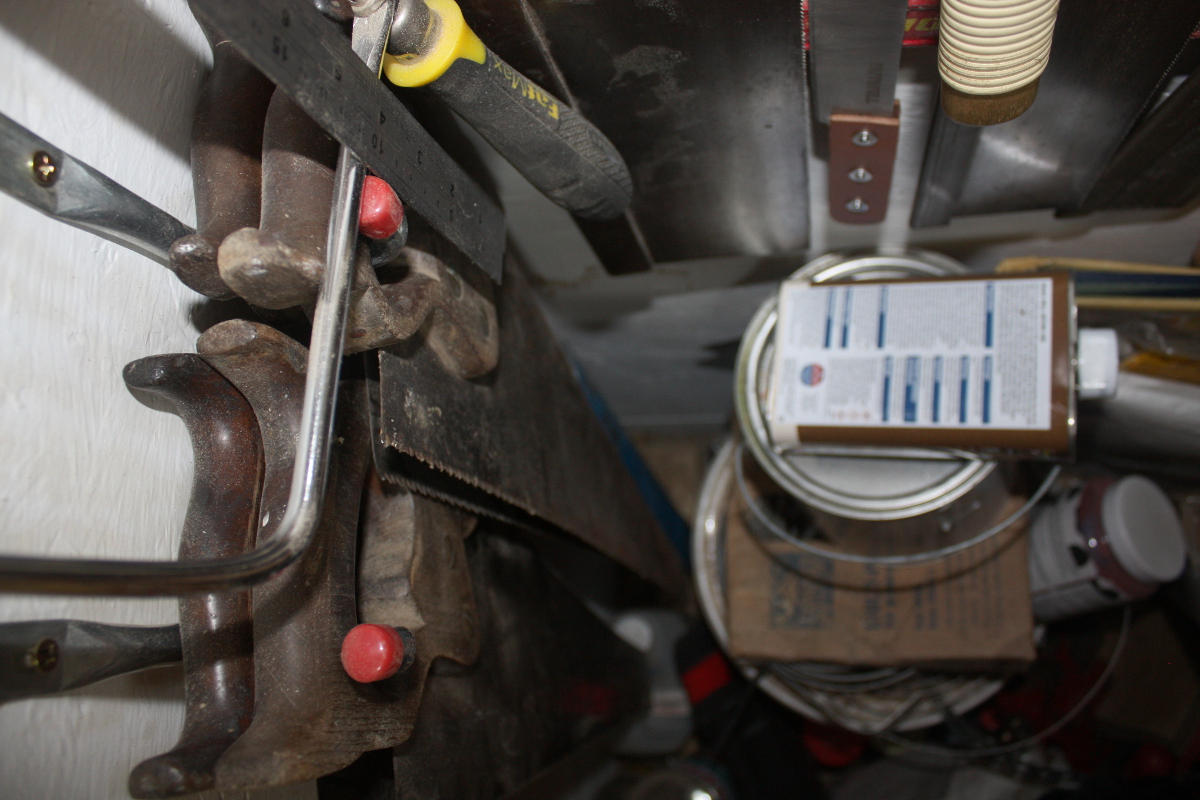

Yeah, I’ve been meaning to try to sharpen these for a while now. I’m not entirely sure why exactly, I mean I get on really well with the japanese saws and the bow saw is fine too, but I got these as part of a job lot on ebay a while back and they’re good examples so I figure I should at least try, y’know? I gave sharpening one of the hand saws a try earlier but you kindof need your saw file to not snap half-way through the process in order to sharpen properly. This time that didn’t happen (sharpening is still a monumental pain in the spine without a higher vice mind you – those saw vices are definitely worth a look if you do this often). Wasn’t hugely impressed with the end results. The tooth geometry still seems off and I think there’s a lot more work to do on those teeth.

The cut is nothing to write home about either.

So, only an hour or so into that five-minute job. On to the next one…

Actually, moving the bandsaw and sander off the “cart” and screwing on the castors only took six or seven minutes. The problem was, with that out of the way…

Well, now I have to tidy up, don’t I? Feck…

Well, granted that took longer than I thought it’d take but okay, I did find a walnut board I’d lost that I wanted to use for the desk shelves project so that was good.

And then I put the bandsaw and sander back, and finally started work on the desk shelves project…

Woodwork al fresco. Just cutting the walnut section for the front of the desk here. Quick rough-cut only, hence the speedsquare and chalk line. You can’t see the tie-dyed trousers in the shot, but it’s 28C in the garden and 36C in the shed after the day of working hard and setting things on fire, so if you think I’m wearing jeans when I don’t have to, well, consider yourself lucky I’m wearing trousers at all.

Right, that will be the desk. It’s a bit smaller than I was thinking originally – 24″ across the back rather than 30″ and 32″ rather than 36″ at the front. That 36″ wouldn’t be seen though because there’s going to be a curve there. But it’s a desk for a six-to-nine-year-old, so it’s big enough I think. Also, this way I don’t have to cut into the good 60″ walnut board and can save that for something else 😀 The angle from front to back, by the way, is the same angle as the sides will be raked at with respect to the ground.

Same angle from the bevel for the desk as for the base and top of the sides.

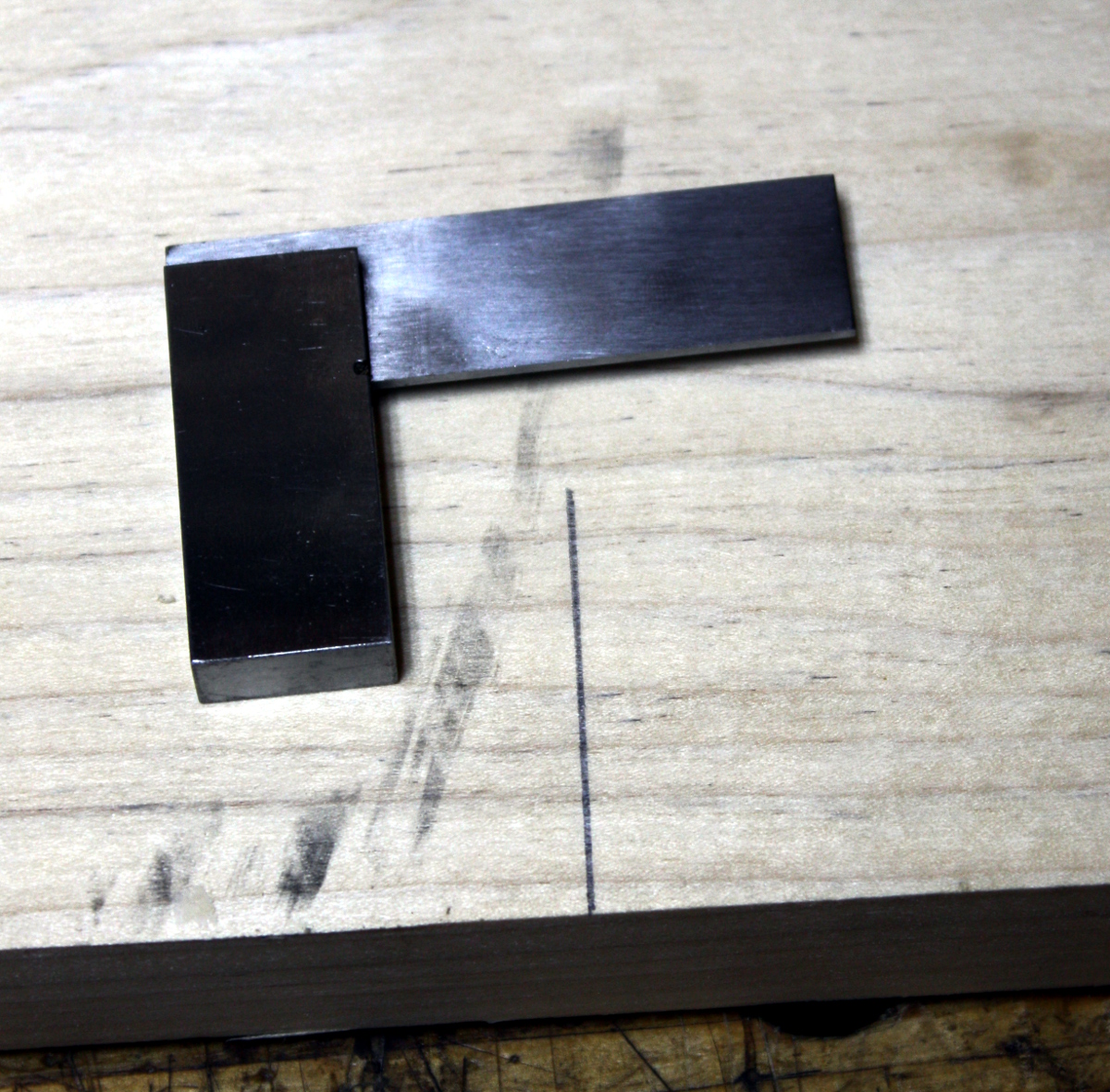

Then I thought that those boards are relatively flat, fairly well matched in thickness, and maybe I could get away with edge jointing them without further prep…

I mean, that should work, right?

Between the #05 and #08, I got the joint to a reasonable fit, and thought it looked okay…

So I went for the glue-up and nope, not a hope, went from fitting to spinning on the midpoint like a top. Tried for a few minutes to get the boards to align, but nope, there was going to be a gap at one side or the other, so I broke it down before it seized up and wiped off the bulk of the glue.

I’ll try again tomorrow. And maybe skim those boards faces first just to be clean about it.

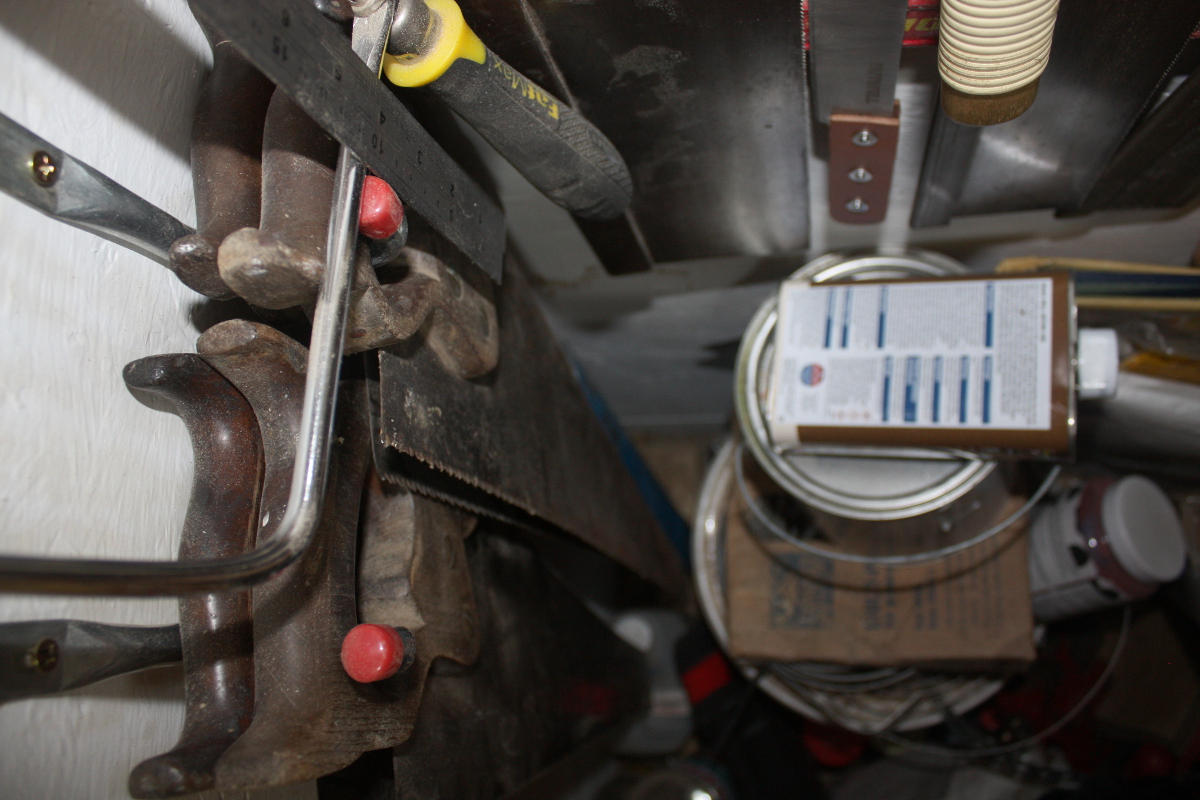

Meanwhile, in the middle of planing the joint, my 4″ square jumped off its perch…

…and did a header into the darkest corner of the shed in an obvious attempt to have nothing further to do with this project.

Can’t say I blame it, but nobody gets out that easily. Extendable lidl magnet light thingy to the rescue…

Seriously, that thing is bloody useful sometimes….

So, tomorrow, a swipe or two to clean the glue off the edges, skim the faces a bit with the #05 to clean them up, and retry that edge joint.

Like this:

Like Loading...

Rather than print it out and trace it onto the stock though, I figured I’d just be a smartarse and draw it from the likely origin.

Rather than print it out and trace it onto the stock though, I figured I’d just be a smartarse and draw it from the likely origin.