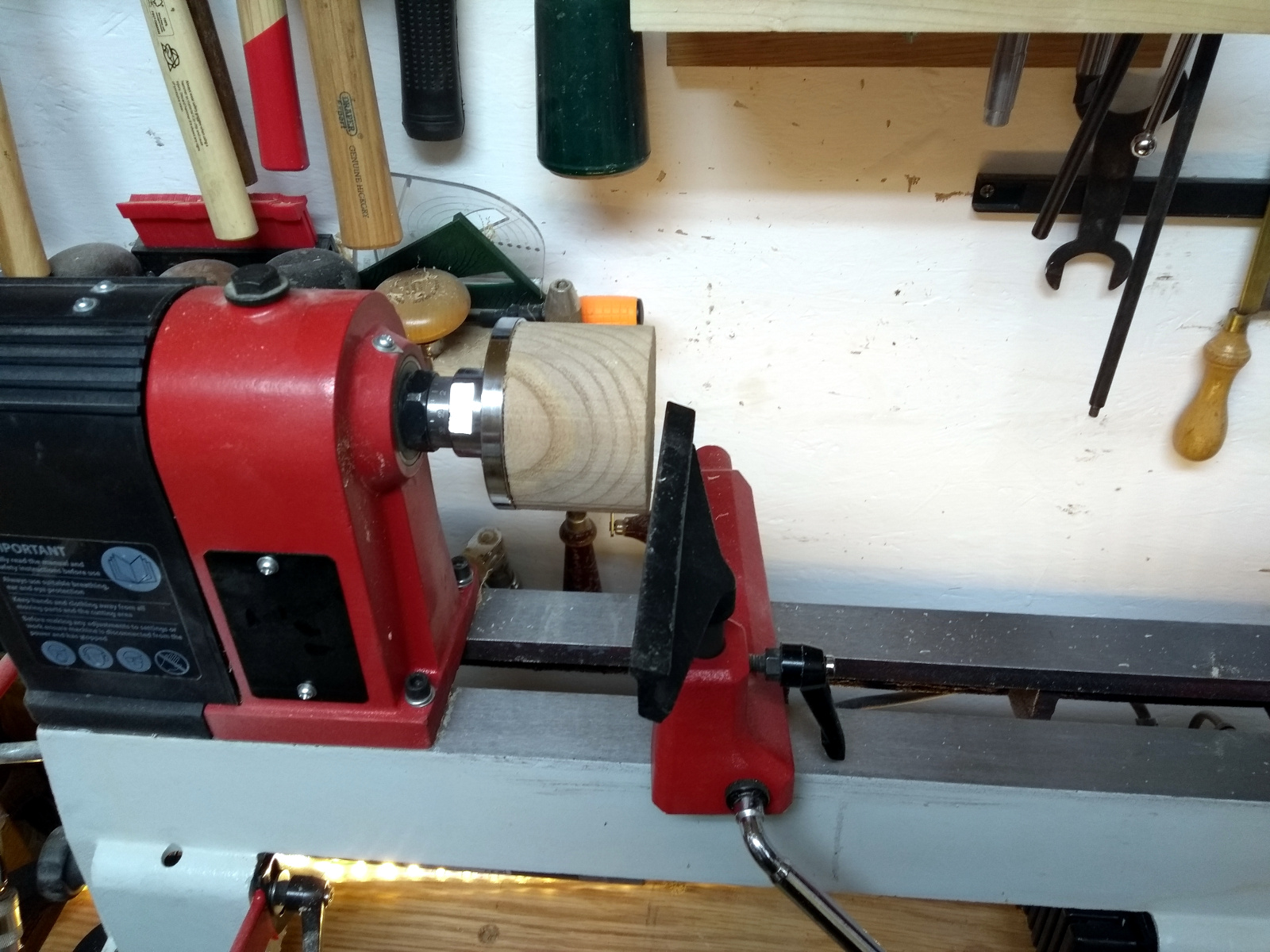

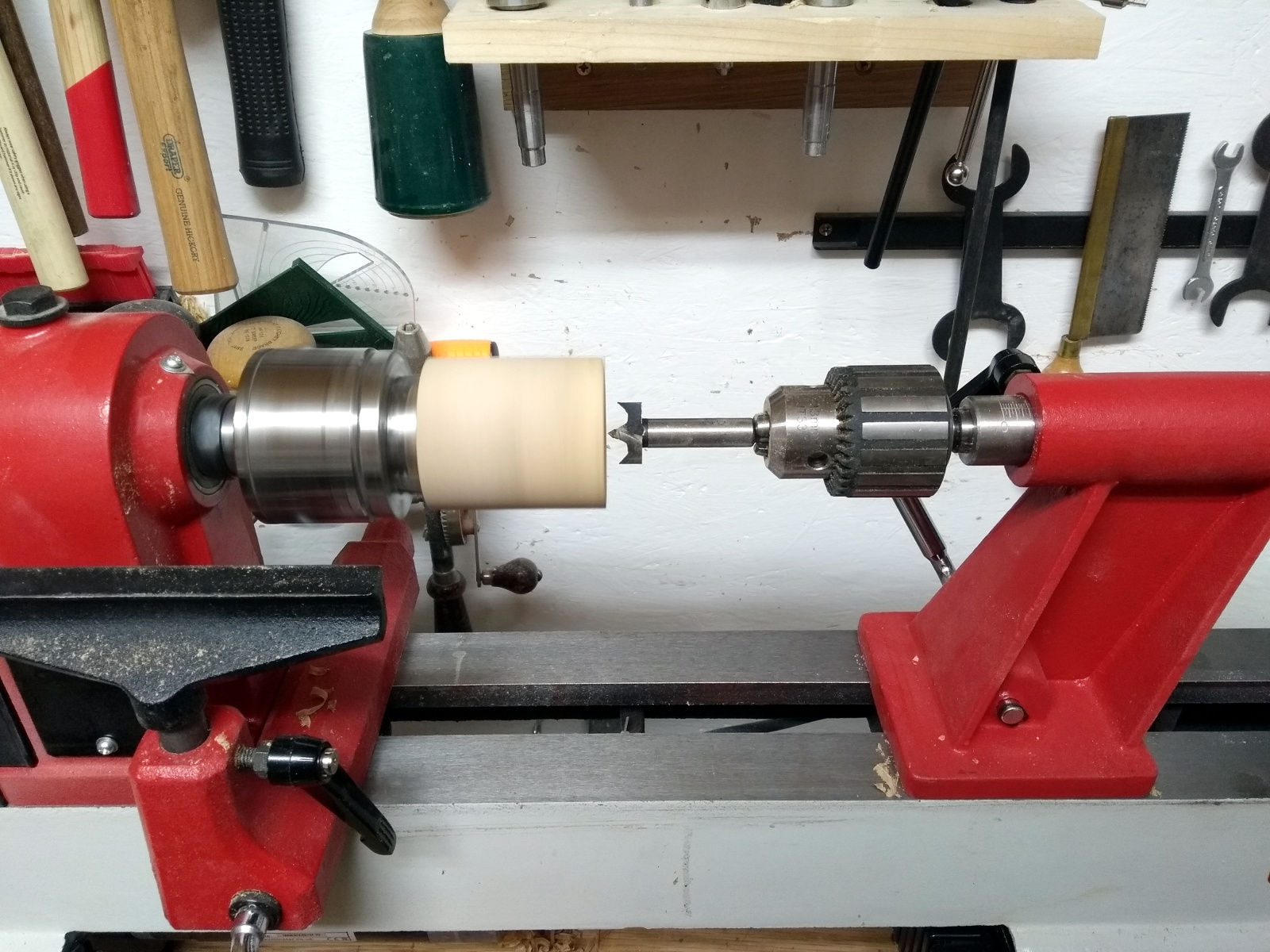

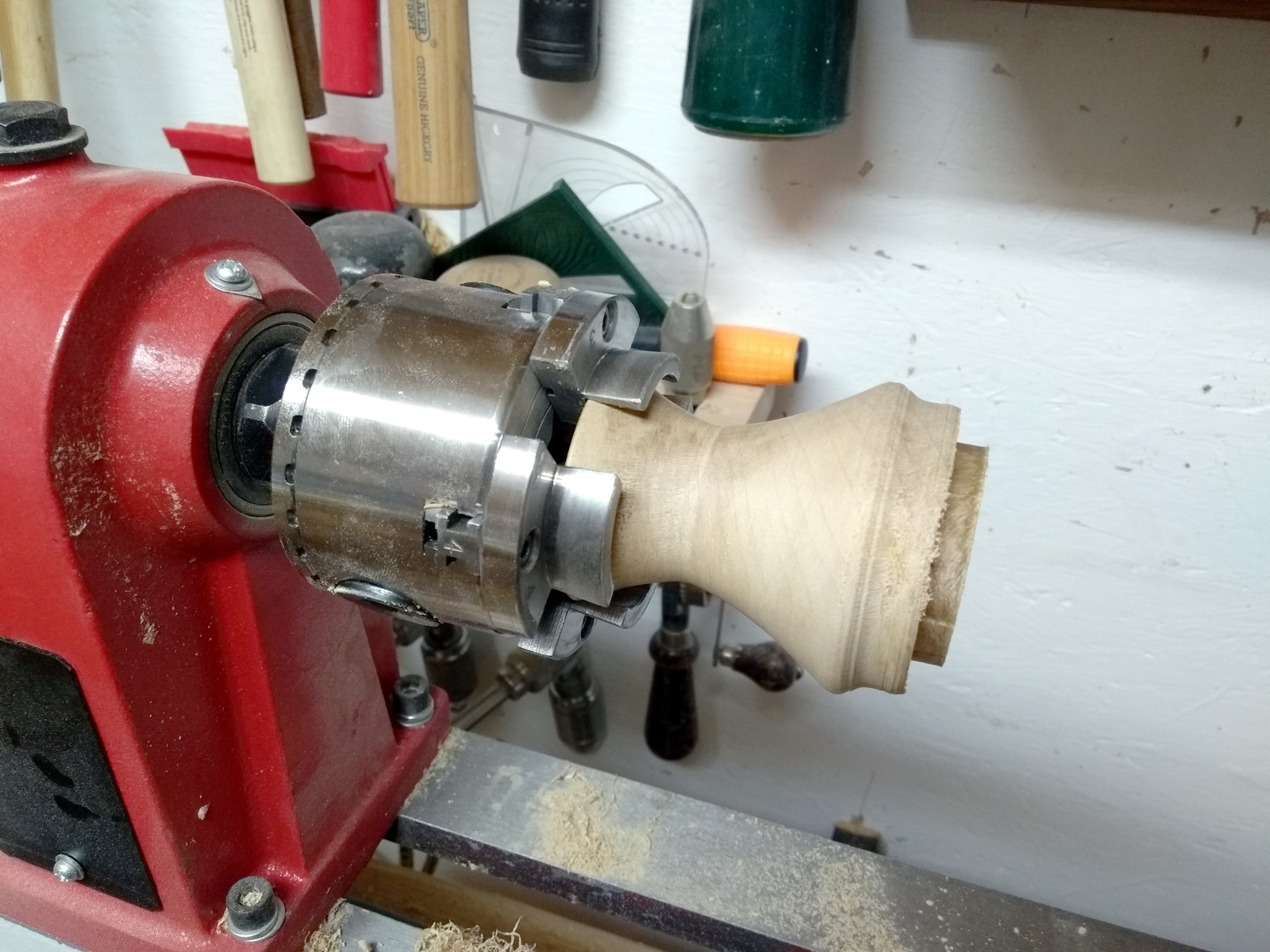

So after the last small bowl, I was wondering just how thin I could make those walls before they gave. Another 3″ sycamore blank in and away we go…

That’s not too bad. But it’s a crummy photo. So… new toy 🙂

It’s a cheap 40x40cm photo box from aliexpress. So now, new photo, same bowl…

And suddenly it looks like I’ve actually gotten better at this 😀

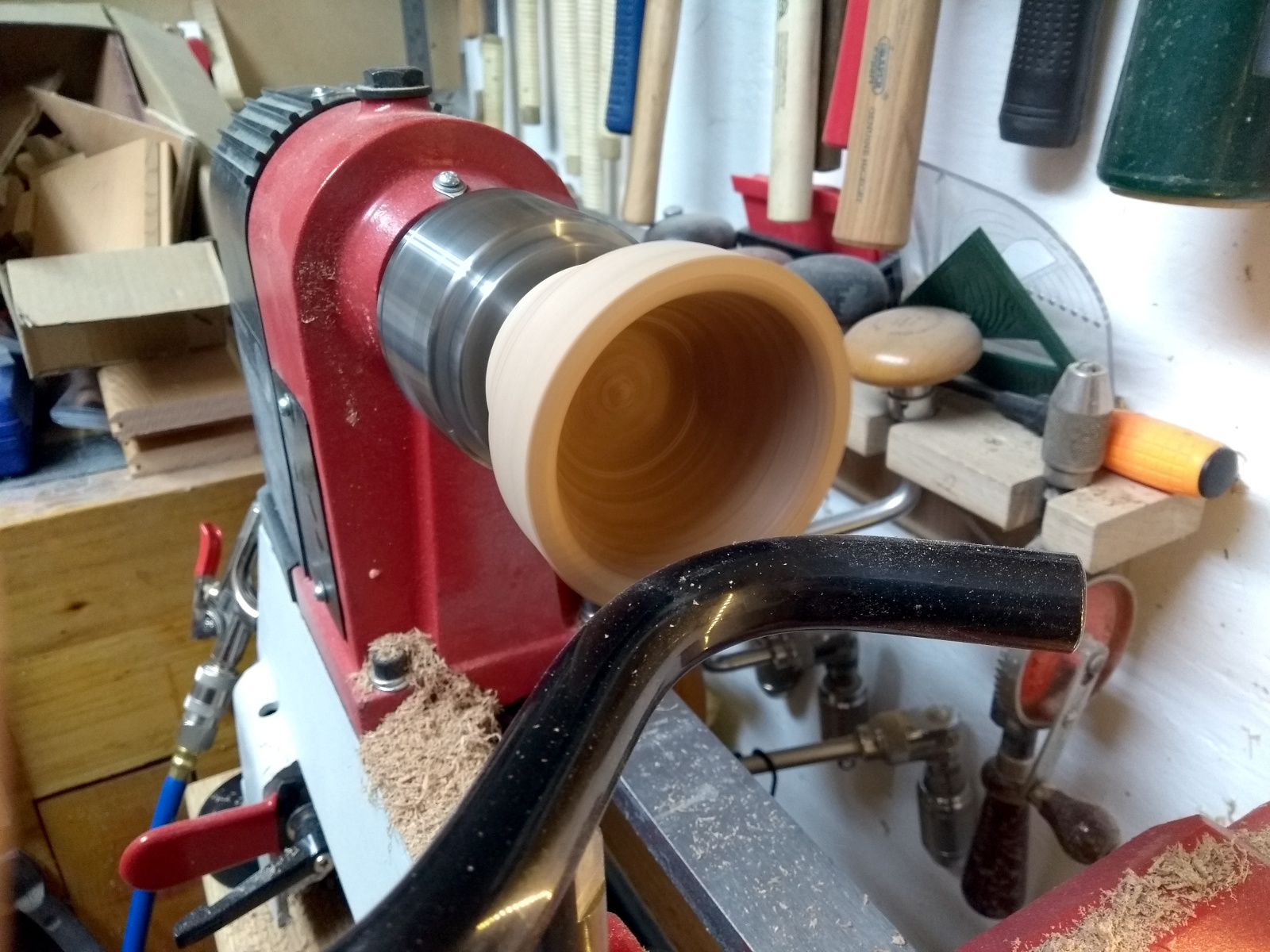

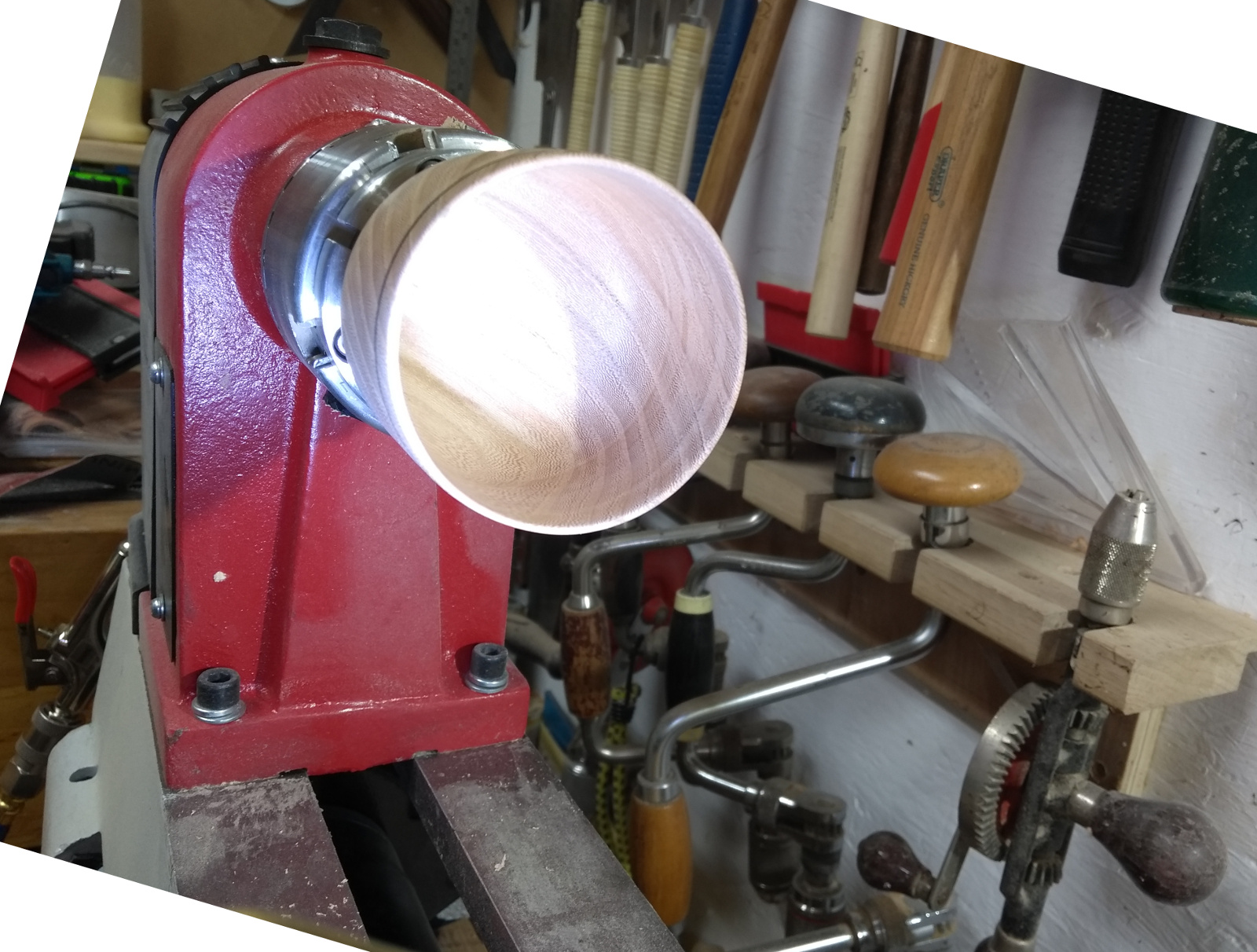

This is kindof a shallow bowl by the way, and bottom-heavy, there’s a centimeter of wood left in the bottom. It’s a jelly-bean dish for Calum 😀

Lovely pretty wood on it too. Simple poppyseed oil and blonde shellac finish.

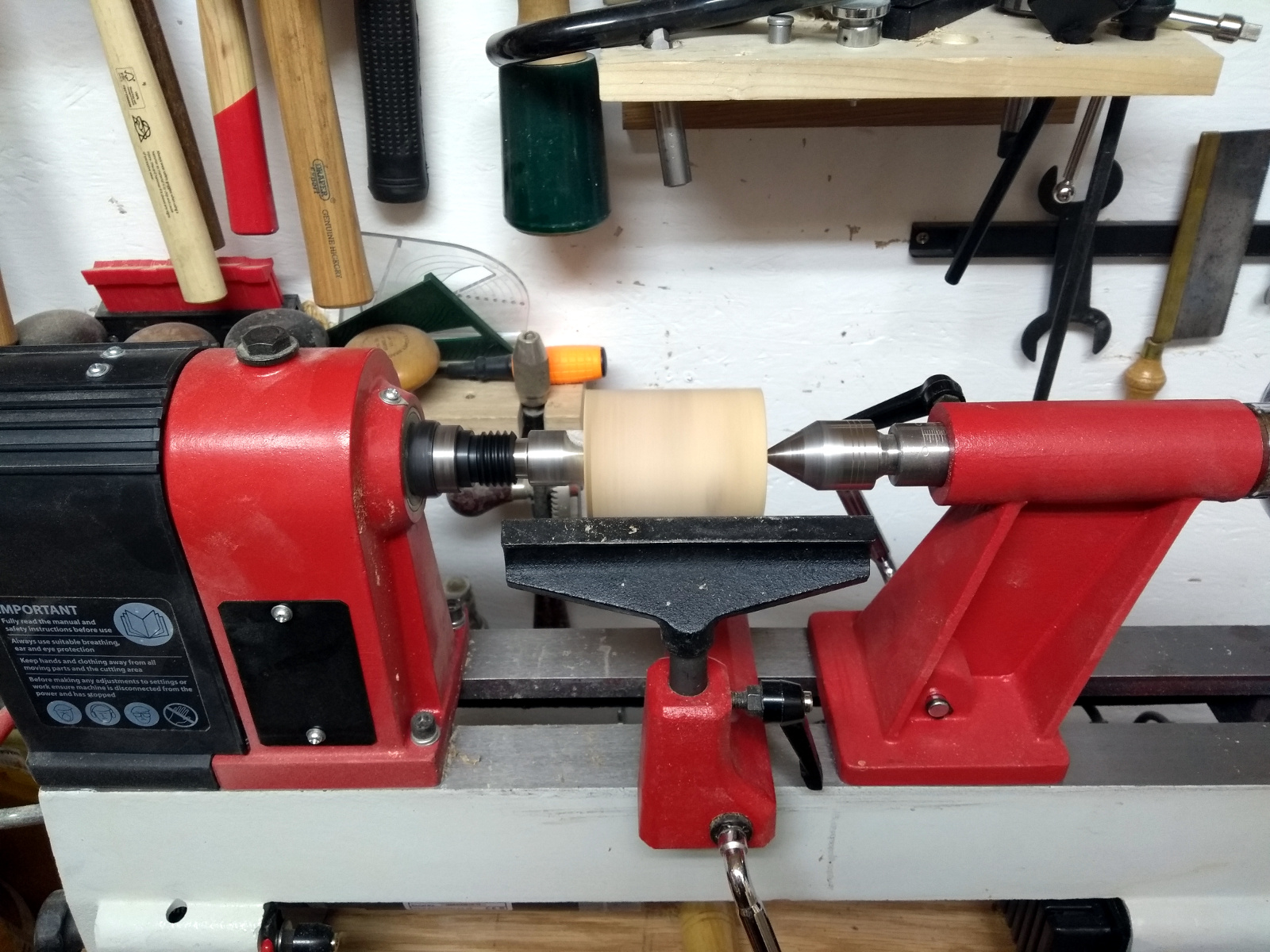

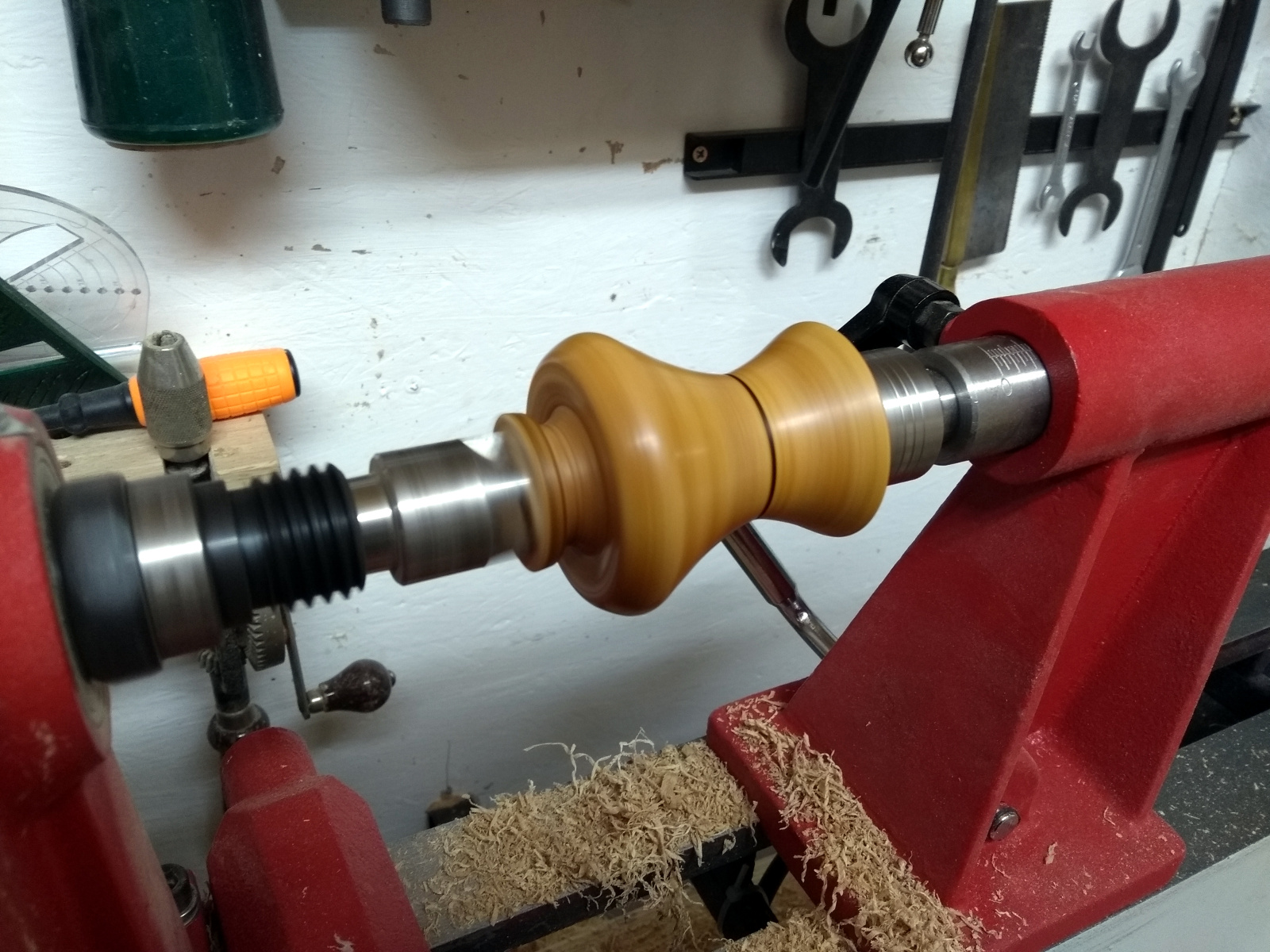

And then, in case that was a fluke…

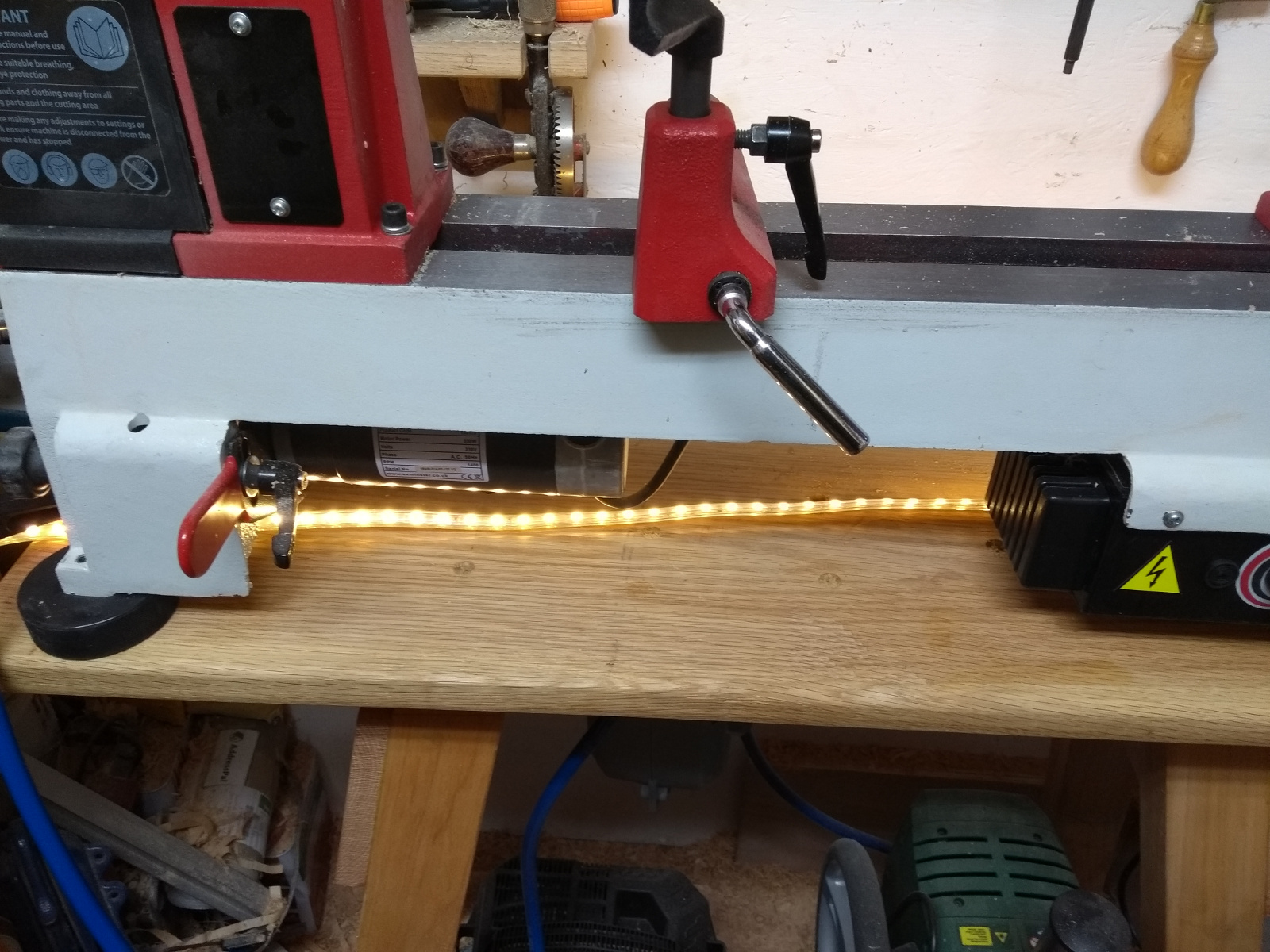

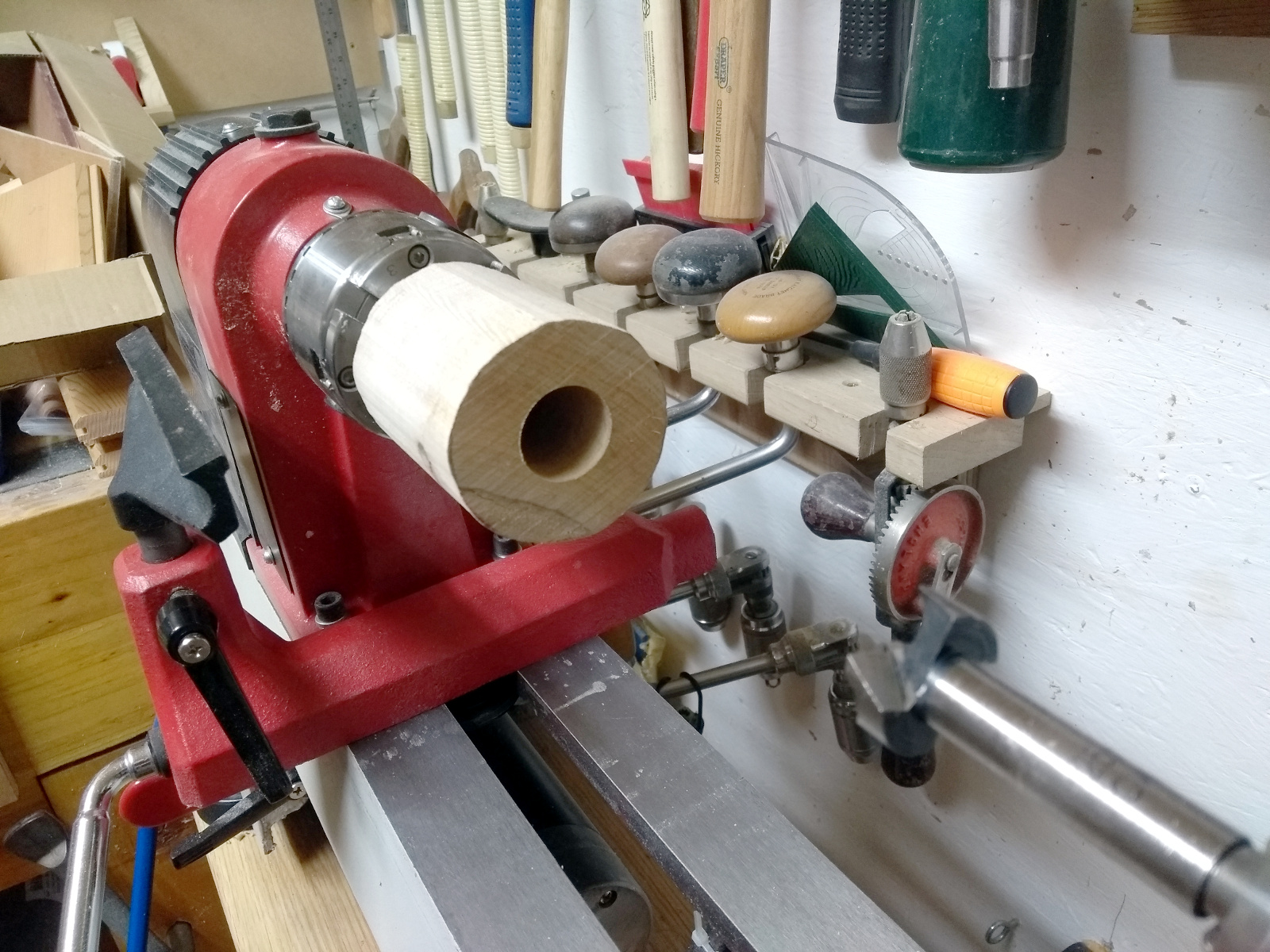

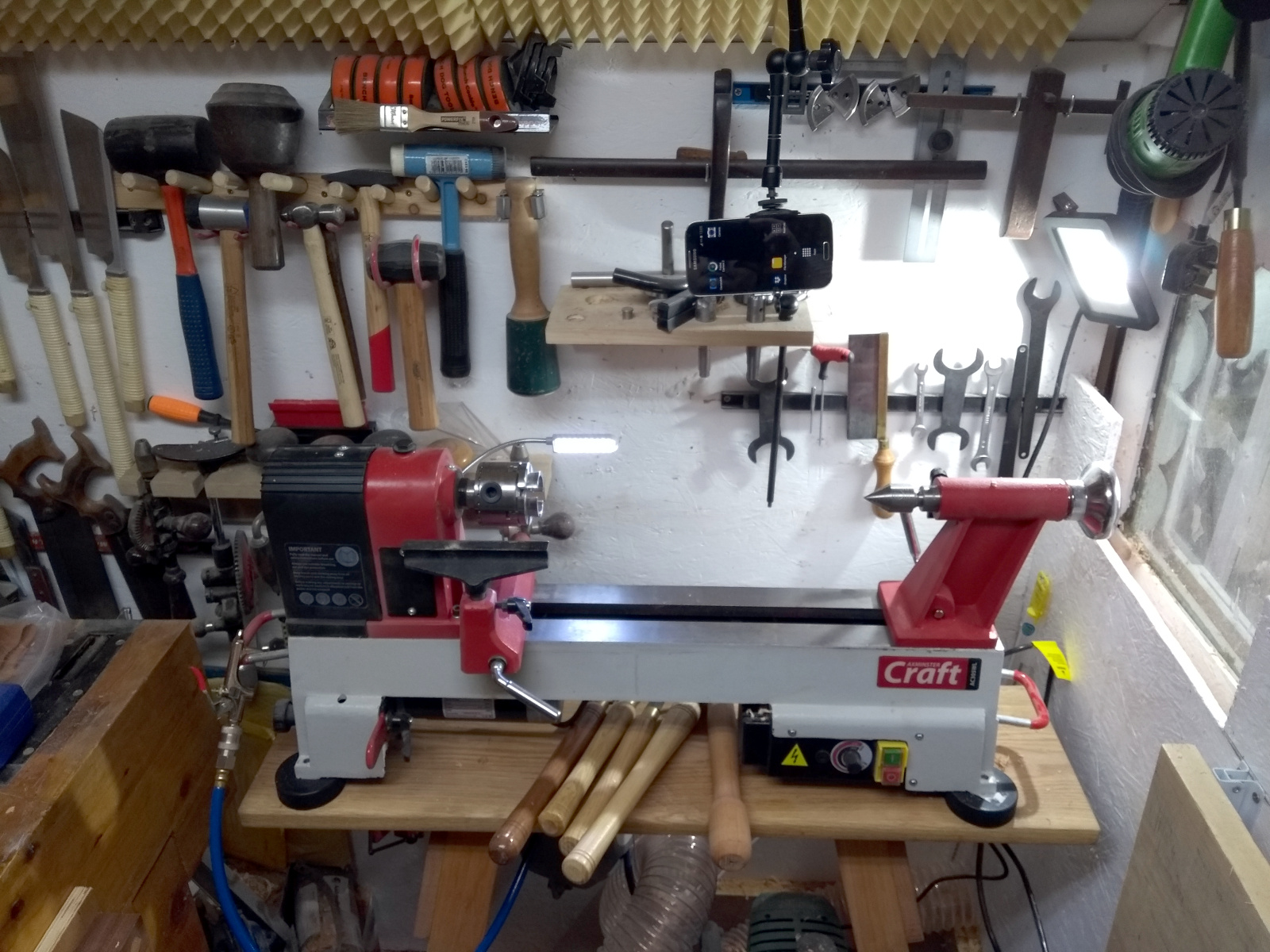

Not as much figure as the last blank, so added a burn line to make it interesting. It’s amazing how important seeing what I’m doing is to this so I had to address the shed lighting again…

Cheap (about six euro) LED floodlight from Farnell and a sewing machine LED light on a magnetic base for task lighting and it’s a massive improvement. And I also put a quick MDF shelf across the feet of the lathe stand and sat the compressor and pillar drill on that instead of on the floor, and now I can horse the entire lathe around about 45 degrees clockwise so I can get better access at the inside of the bowl. Makes things a bit easier.

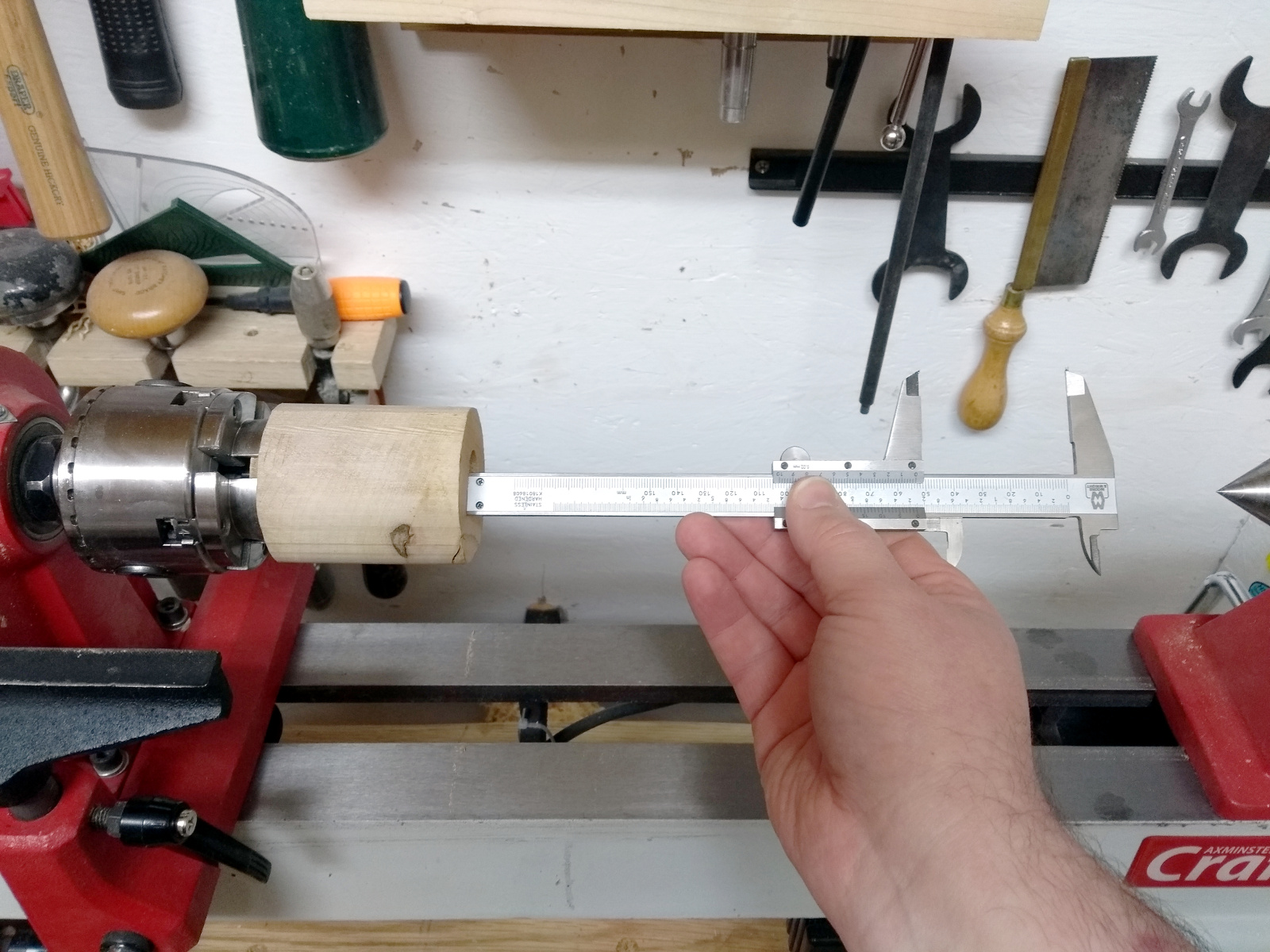

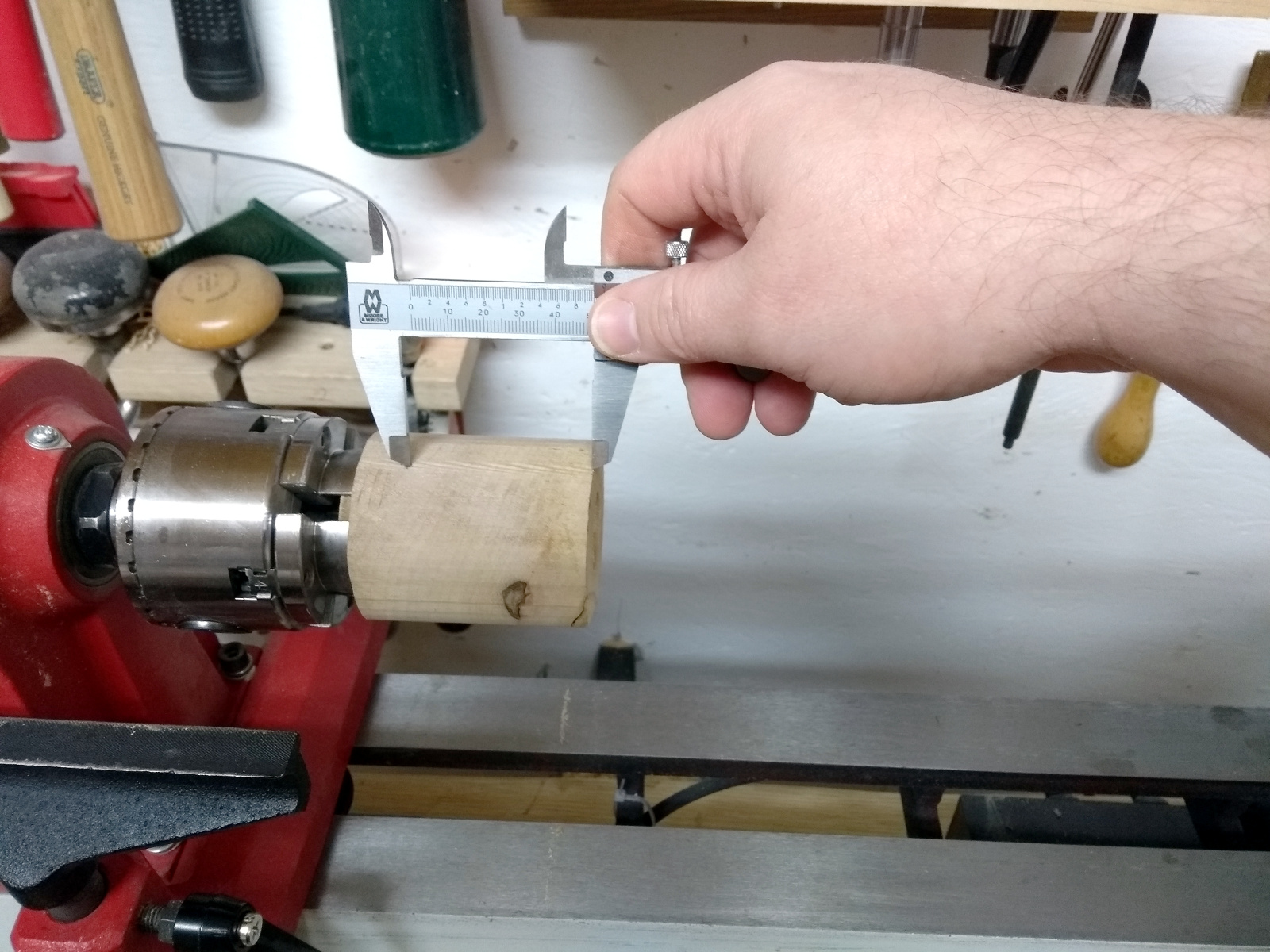

I think the walls might even be thinner on this one. Fraction of a millimeter, but it just feels a little lighter.

Think I might be ready to move to a 6″ blank now…