The machines in the shed take up too much room.

And even the support machines for the machines take up too much room.

But the bandsaw does earn its keep and you can’t do bandsaw boxes without the sander and the thicknesser just removes the worst of the donkey work (and face it, in the 17th and 18th centuries, you had thicknessers too, you just called them apprentices) and you can’t use any of them without dust collection (well, you can, but the cleanup takes longer than doing the job by hand would have most of the time). Hence the shop vac and the cyclone. But they’re all just piled on top of each other and the bandsaw and sander are in a huge clunky cart that I threw together as fast as possible rather than making properly. So I need a cart for the dust extraction (with a shelf for that box of supplies that has wound up in that space) and I want to remake the one for the bandsaw and sander so it takes up less room because in the shed literally every centimetre counts (it’s a metric shed 😛 ).

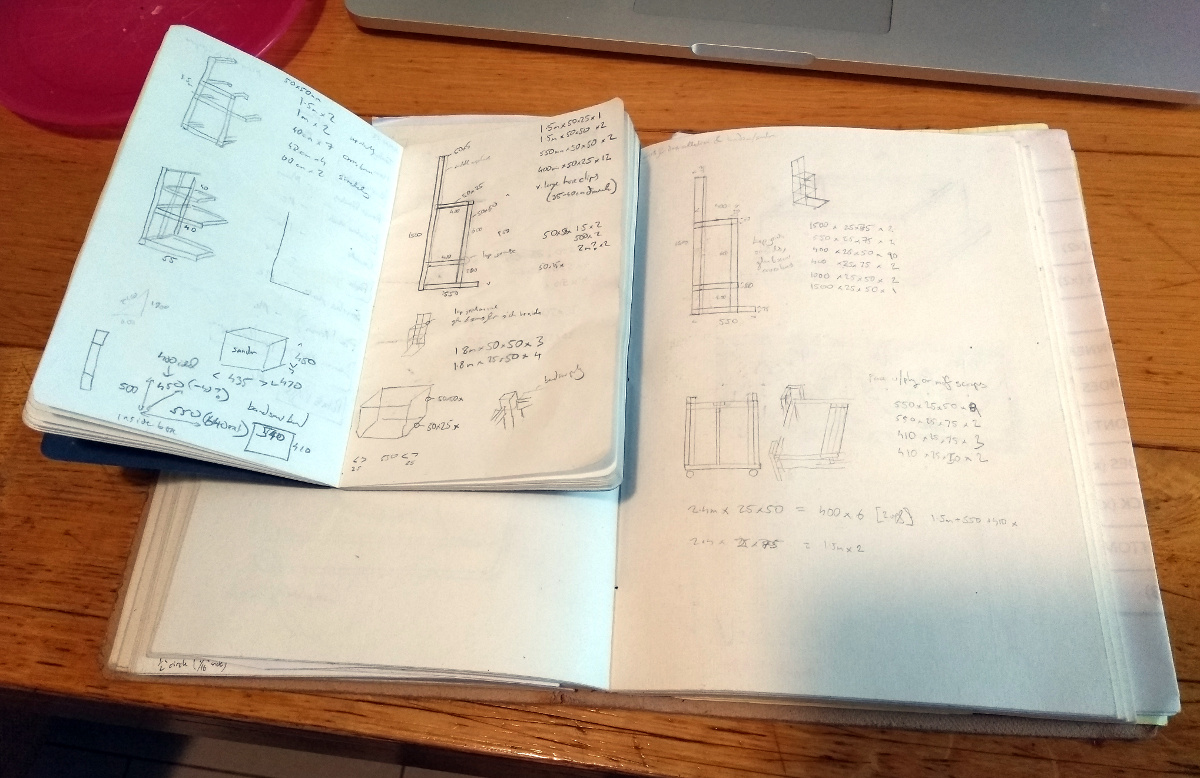

So, watch a few youtube videos, browse a few google image searches, doodle in the nearest notebook with blank pages for a while, then work up a plan and a cutlist. This is still a shed cart, which means that it’s going to be made on the cheap, from whitewood, and is expected to have a life expectancy of only a year or two. I do want to leave enough room to upgrade the shop vac to a proper extractor, but happily there’s a proper extractor design sold by a few companies that is almost the same size as the shop vac. Then off to woodies on saturday evening because Brooks closes at lunchtime on Saturday. Bit more expensive, bit worse quality, but workable.

Hooray for the yeti, it can take 2.4m lengths of small cross-section timber without any folding of seats.

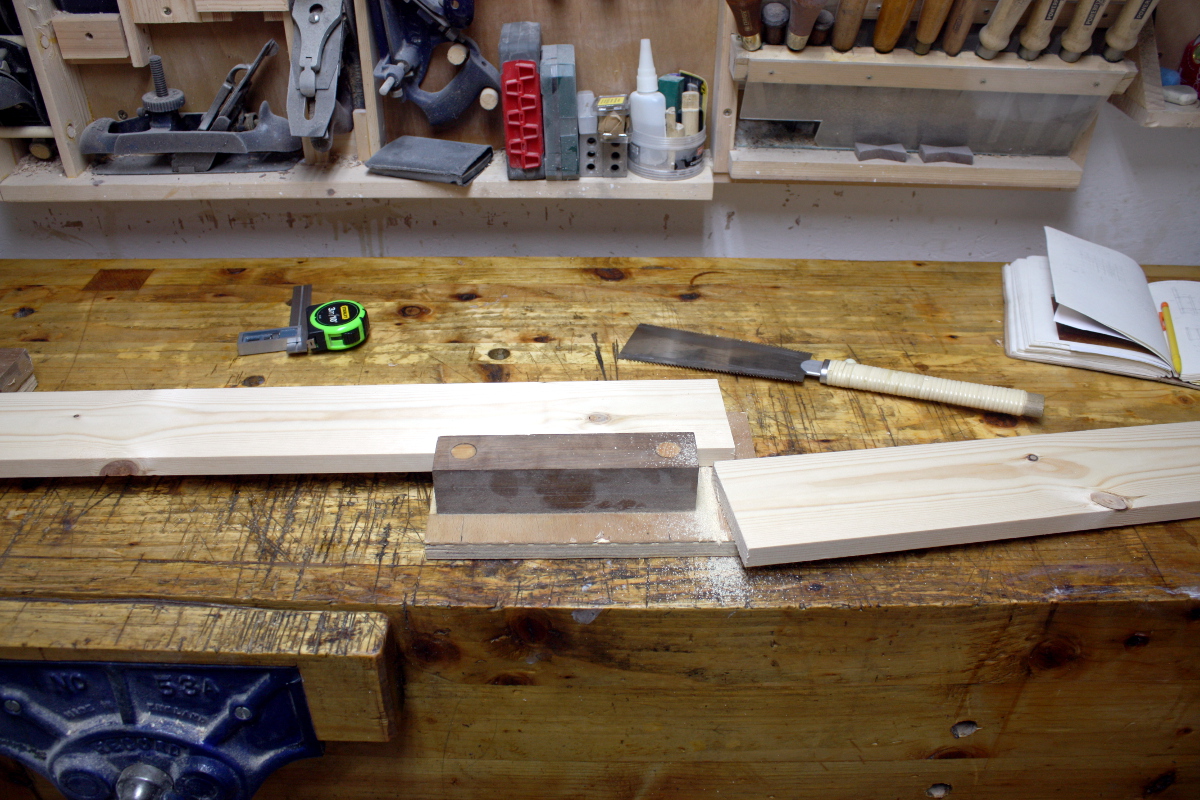

And stashed overnight (those are packers drying on the bench which are to let me bolt the new fence to the bandsaw, more on that later). The next day, out with the sawhorse (because I can just about stash a 2.4m length in the shed but I can’t work on it there – yes, that does mean there’s more room in my car than in my shed). And lots of cutting to length.

With the parts cut, I started on the bandsaw cart – I figure it’s smaller, it’ll be easier to do and get more room to do the larger one. The base is built with lap joints more because I’ve not cut joinery in ages and I wanted to than for any good reason, if anything it would have been better not to have cut them at all. But, I got a new cutter for my #071 (it’s one of the veritas ones and if you turn the height adjust nut on the #071 upside down, the veritas cutters fit) so I wanted to use it.

Mark off the width of one board against the other with the knife, saw the tenon shoulder, split the cheeks off with a chisel in the vice, clean up with #071 and the #062½ block plane, repeat seven more times.

Notice that one board is canted, curse a bit, fettle with the block plane, douse in glue and clamp with screws. The rest of the frame is butt joints and pre-drilling to limit splitting and screws and has more in common with framing than with furniture really.

But hey, it works.

See? Not falling down and everything fits (actually better than before because there’s more clearance for the sander’s spindle). It does rack too much for my tastes, so I’ll screw on plywood panes to act as shear supports (and limit the ingress of errant shavings and dust), but that’ll be tomorrow.

I might add in a few glueblocks to give more compressive strength on those legs as well, but I think it’s a success so far – there’s a noticable increase in room where before there was an annoying 2×4 in my leg. I might even break down the 2×4 cart (no might, I will, I have nowhere to park it) and reuse its metal reinforcement straps because why not.

Farewell little cart, you’re about to be torn to pieces and recycled.