So this showed up at work today, making excellent time from Rutlands in the UK:

New dust collector! 100mm dust port, 1100W motor. Should do grand with the thicknesser and I’ll use the adapter that’s currently going from the existing dust deputy to let me hook the extractor up to the cyclone (100mm cyclones, it turns out, are spectacularly expensive, but I might just build a cyclone lid following this page’s instructions, which would also reduce the overall height of the stack.

Yes, I need to unscrew the joint, break the glue joint with a lump hammer and then the frame can flex the 10mm it has to so the extractor can squeeze in. It’s not great, but this wasn’t supposed to be an heirloom piece 😀 It’ll do for now. It’s not like I empty my shop vac every week anyway.

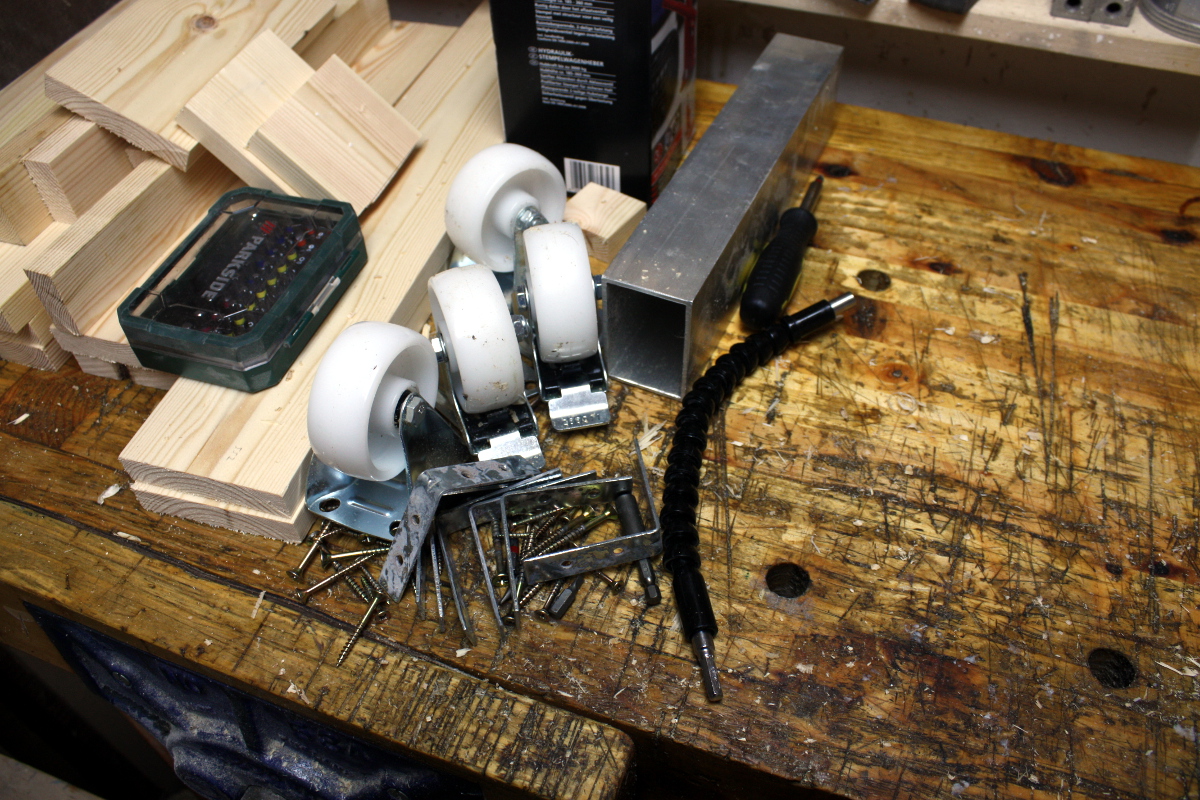

Next up, install the castors and the shelves on the cart and put things on it where they’re supposed to go so I’m sure it’ll all fit.

Right, need to extract the shop vac and retire it somewhere, then tidy up this disaster area, use a ratchet strap to secure the cyclone and its canister in the frame, and wheel it into here so it backs up against the wall and gives me a few square inches of room more than I currently have and reduces the odds of an avalanche trapping me in the shed under a few cubic feet of oak and brass stock and stringing…

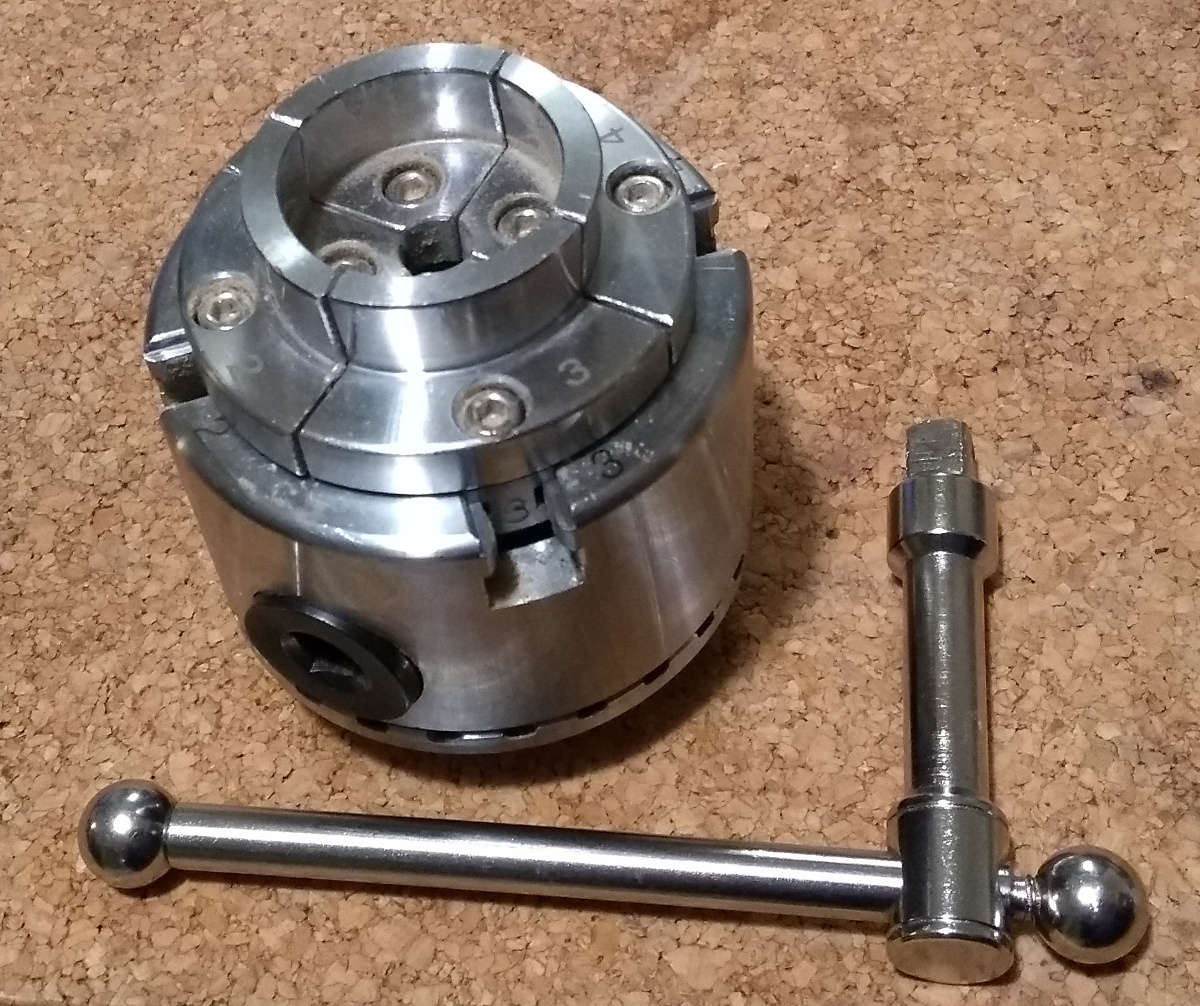

There were a few other things tucked in as well, but there’s so little room in the shed while doing this (I had to screw the castors onto the cart while it balanced on the cardboard box the extractor came in, while that stood on the old cart outside the shed and the botom of the new cart poked in the door). But I did want to take a peek at this…