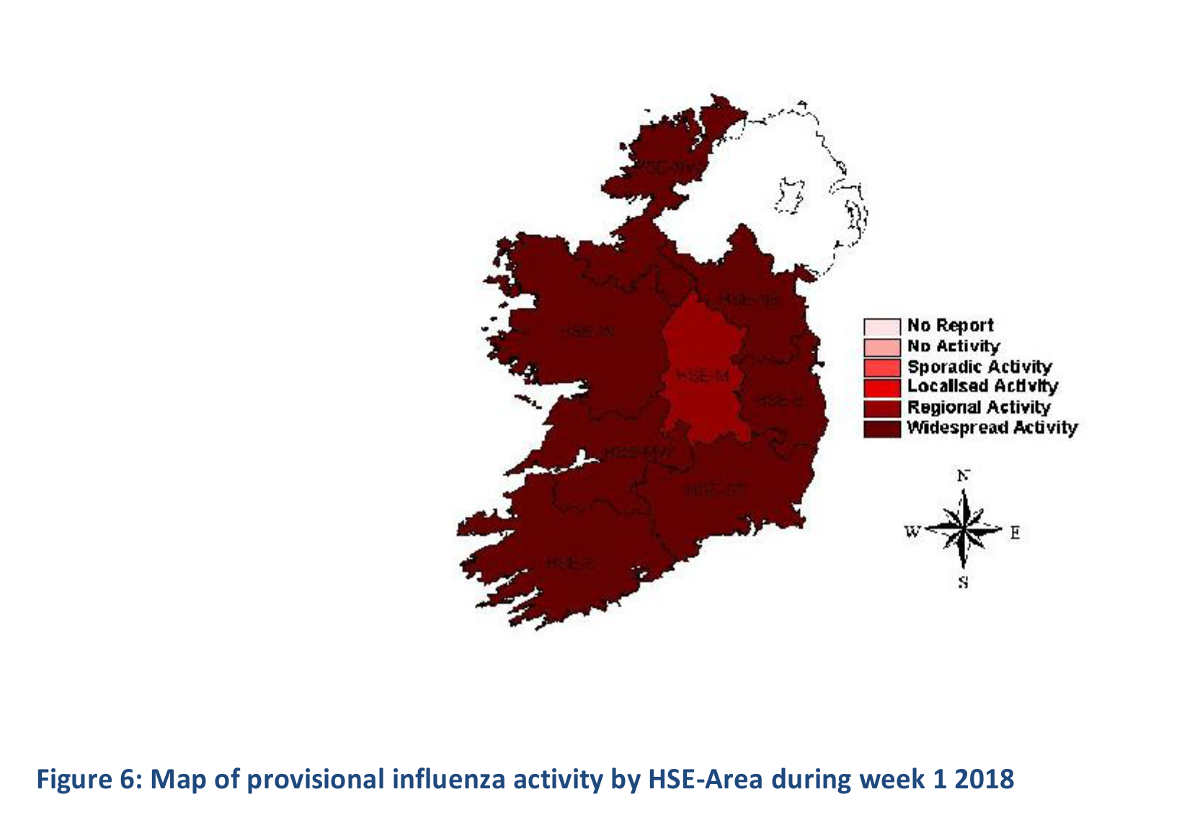

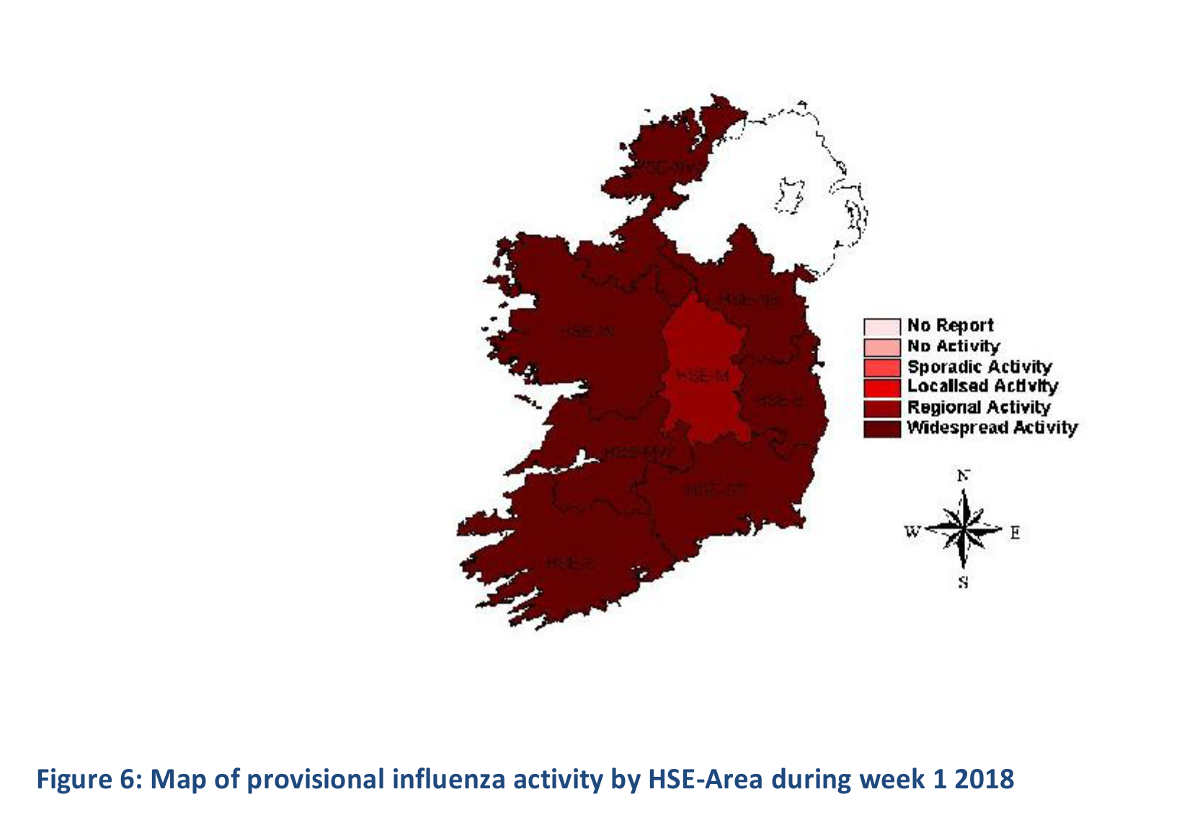

So I get the ‘flu shot every year, but apparently the strain picked for the shot this year did not tally with the strain that showed up in Ireland (apparently from Australia of all places) and it’s been rather rampant of late…

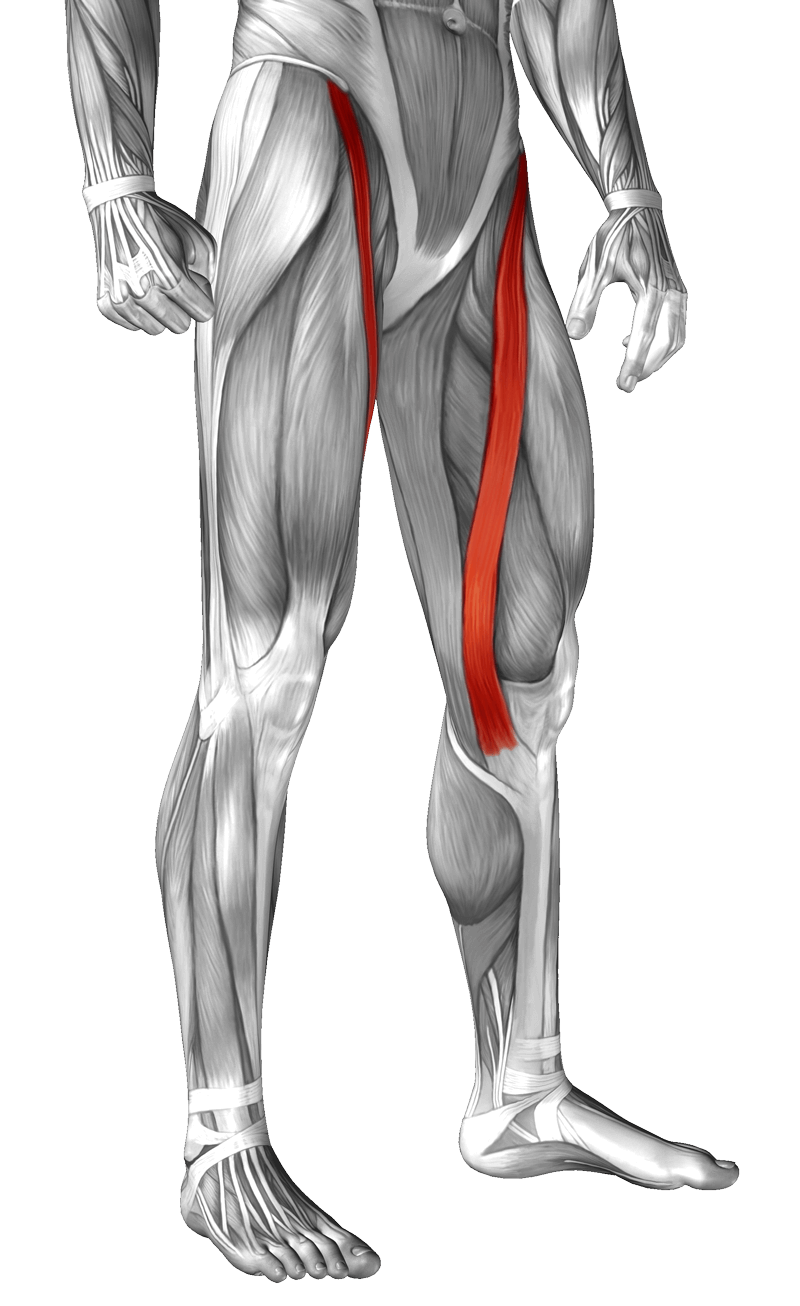

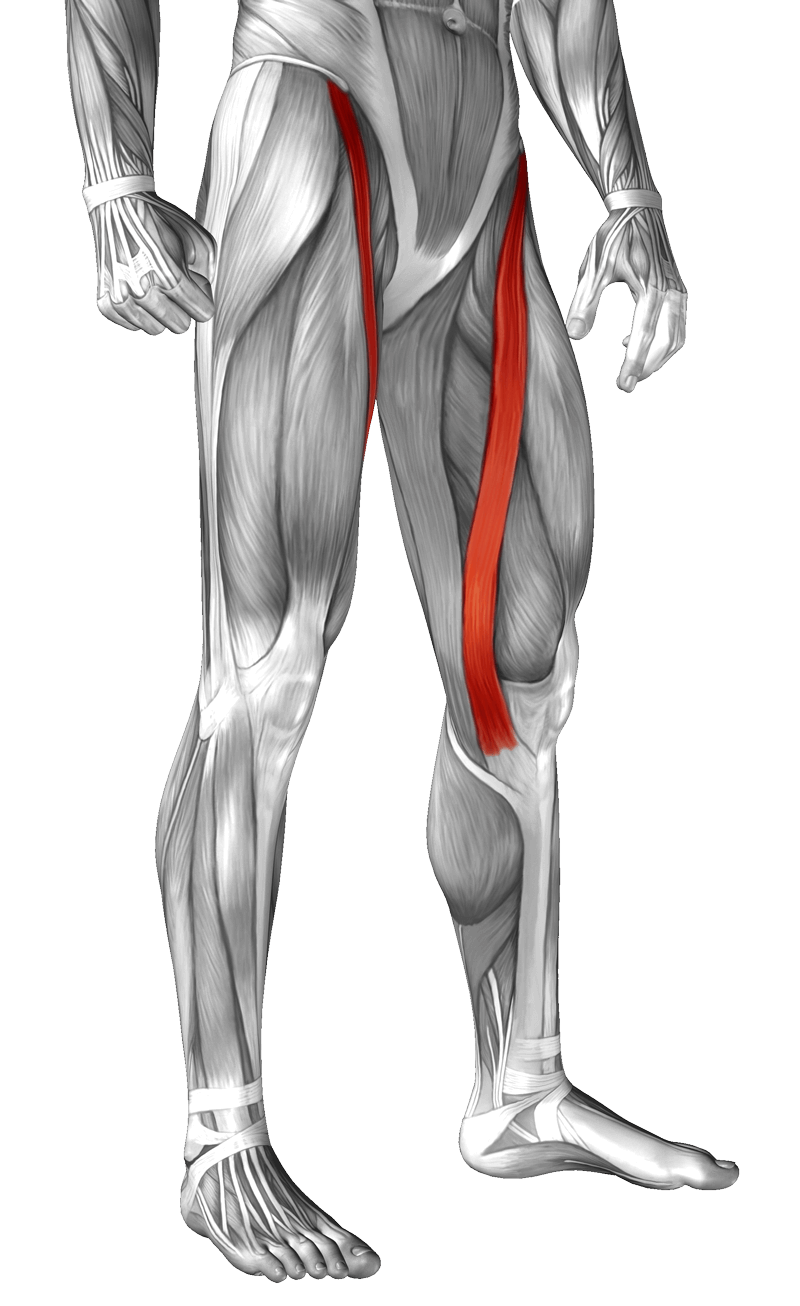

Also, in an unrelated topic, meet the longest muscle in the human body, the sartorious muscle:

So, can you guess what happens if you catch the first and pull the second? Did you guess four days flat on your back in bed doing nothing shed-related past reading Alan Peters’ book on cabinetmaking (interesting read btw, as it’s less “here’s how to cut a dovetail” and more “this is how you run a successful woodworking business”, which is a nice look into a different world) and watching an endless train of Japanese cabinetmaking and Roy Moore videos? So the project I was working on has stalled until this evening bar an hour on Sunday. Yay.

There are however, some new toys. So here’s my current dust collection rig:

Yes, I collapsed it, but it still works. I need to build a safety valve. However, it’s also a 60L drum because when I ordered it I didn’t quite know what I’d need and I was overly cautious. And now it’s eating space so I wanted to downsize – so I ordered a 30L drum and it arrived right after christmas, just when I couldn’t do anything with it.

So I’ll try fitting that as soon as I get a chance (it’ll have to be a weekend I think). That should get me a chunk of space back.

Also, I was watching Peter Follansbee again and he was making pegs for drawbore joints and he has this lovely mini meat cleaver thing for the job:

All I have to use is an inch-and-a-half chisel which is not the most stable of arrangements because you’re trying to hit a point a foot in the air above a peg-sized piece of wood balanced on end and held in place only by the chisel edge which is neither easy nor terribly safe. However, in the video Peter mentioned that a glazier’s hacking knife was a good modern substitute, so I looked them up and they’re dirt cheap and I need pegs for the current build so…

One cheap hacking knife. Should be far more controllable and safe for the splitting, but we’ll see. I kinda want to take the grinder or a file to the point of that thing and get rid of it though, just have a flat blunt end at the front of the knife.

And the pin chuck I ordered last year arrived…

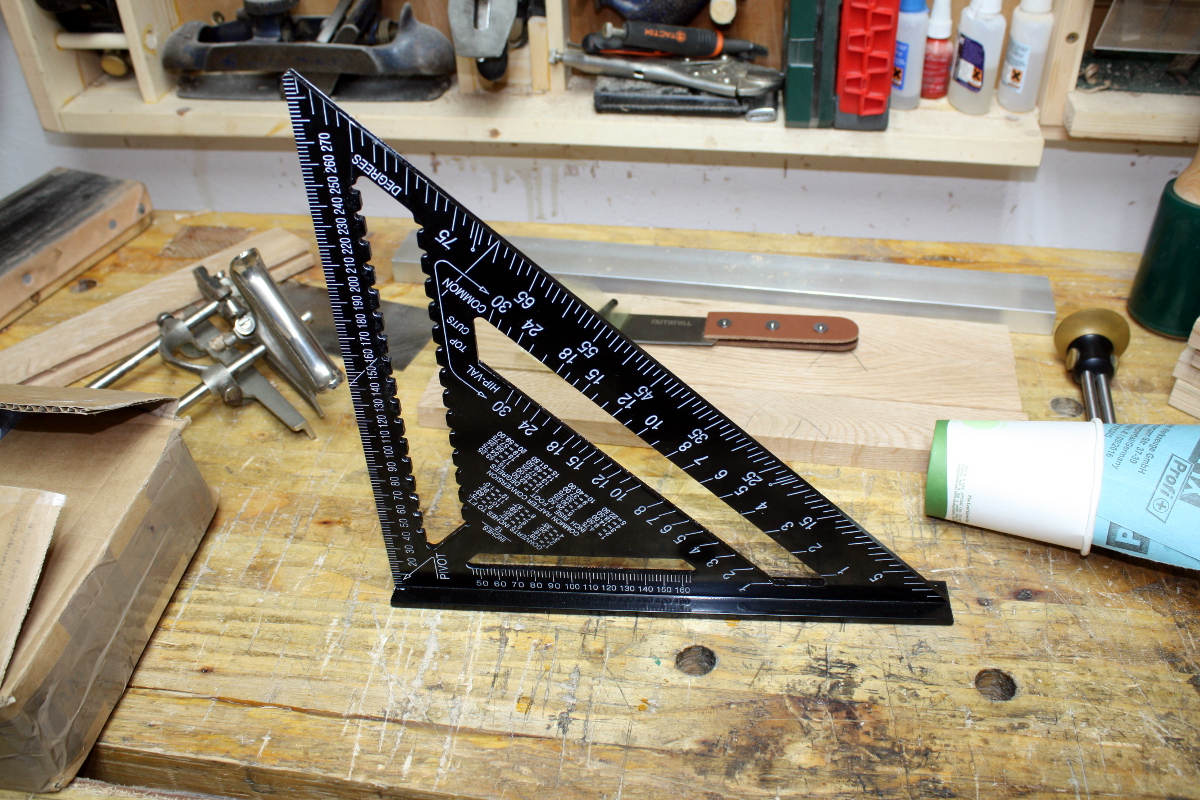

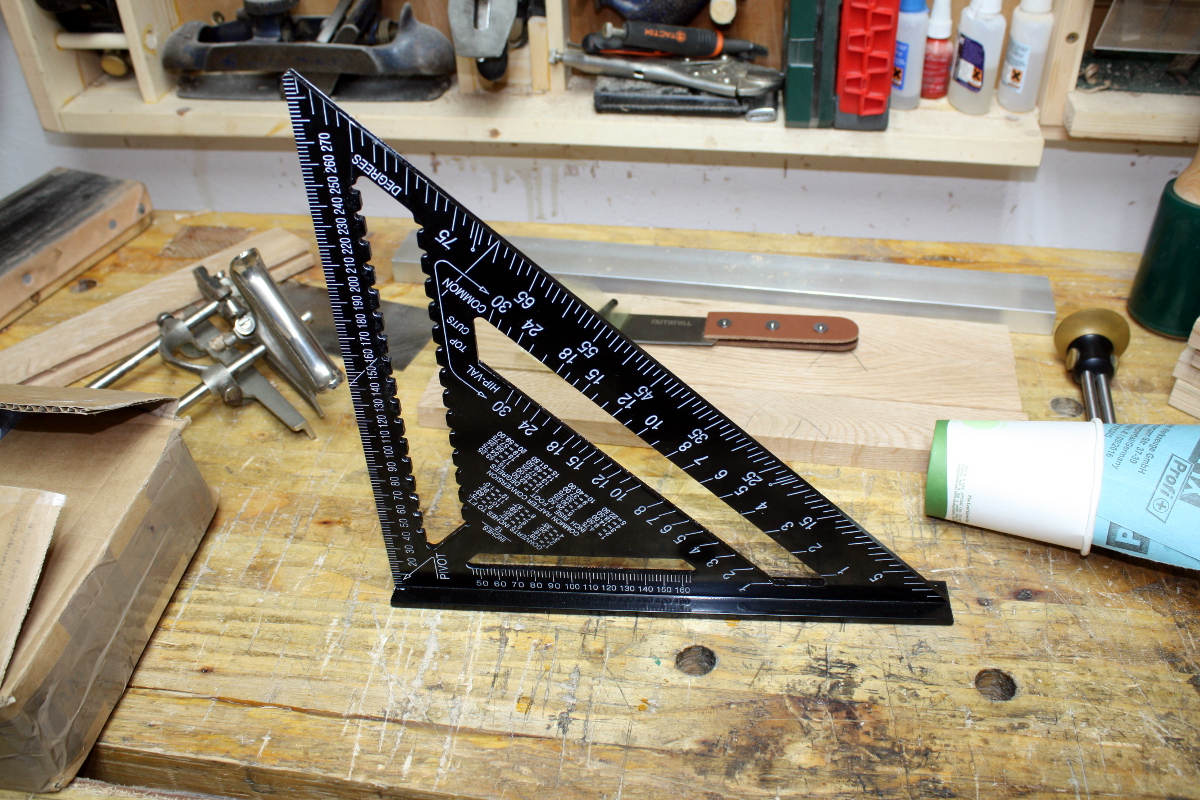

along with the 12″ speed square I’d ordered (mostly because this is the tool I keep wanting in the timber yard rather than the framing square I have at the moment):

More tidying may be needed at some point 😀

Oh, and a few places on ebay were doing sales on brass hardware so I picked up a box of the things because after the wall cupboard build I didn’t want to get caught without a handle at short notice again. And some hinges because I looked at the shiny brass against the oak for the current build and it’s not quite right. But we’ll see. Mostly this is just stuff bought because it was going for less than half price.

And these were a few design punches bought for very few peanuts as part of the whole “learn 17th century carving” idea. They work great on something like walnut:

(That’s my reference stick for my gouges in case you’re wondering)

But in oak, which the carving is done in:

Just too faint to be made out. Too much detail in the punch for the grain of the oak to take on. Oh well. Into the toolbox for later they go. I have a few more that were ordered off ebay that are on their way, I’ll give those a try when they get here. At least two or three of those are re-workable with a file but seem to be the stippling pattern Follansbee was using in his work. They won’t be needed for a little while though, thanks to the flu delaying everything.

So I got back to grooving the rails tonight – or at least tried to. I’ve been having some issues with the grooving using my Record 044. Ralph over at Accidental Woodworker has been having some issues with his as well, and I thought it might be a common problem but it turns out my fence is aligned okay. My skate’s bottom isn’t perfectly at 90 degrees to the skate sides – you might just be able to make that out in the photo – but it’s only out by a few degrees and it’s so narrow that can’t be the problem either. The grain on the oak is squirrelly and reversing half-way along the rail, but I’m getting horrible tear-out before I even get to that point:

That’s with a freshly sharpened and stropped iron (even worked the back of it just in case I’d missed that iron somehow when rehabbing the 044). I spelched out through the rail completely on the first try on this one and had to plane back to the reference edge and start over, so when it started tearing out here, I got out the cutting gauges instead of just the mortice gauge and sliced the nearest edge very deeply.

Then I got out another cutting gauge (which happens to be about seventy years older or so and actually cuts better) and sliced the far edge the same way.

Then with the 044 set for a very fine cut I got a okay-ish groove cut down to depth; but it wasn’t even. I used the new Japanese chisel to chop the far edge to properly vertical rather than the gentle curve it had become, but then I noticed that the 044’s fence wasn’t even in contact all the way along to the same degree. I must have been tired – it took another five minutes of staring at it before I realised that the rail was twisted.

I planed and prepped it to flat in early December; sitting in the shed through a few cold snaps and 60-70% humidity with the squirrelly grain in the wood must just have been too much for it and it pretzeled itself by a good few degrees. So did two of the other long rails. The last long rail was only slightly twisted, but it’s one of the uglier pieces because of a knot. The short rails were still fine and are still perfectly flat, as are the stiles, so they can still be used.

Luckily I have a rough-cut chunk of an oak board in the timber store that’s only a few mm shorter than the long rails (literally a few, three to four in total) so I’ll plane that flat and rip out new long rails from it. I’ll probably cheat and get most of the way to thickness by resawing with the bandsaw and take them the last mm or two of the way by handplane (I’m now quite short on time for this build and I’ve already been dropping elements from it to try to get this done by the end of the month). The grain’s less squirrelly in this piece as well so I might even be able to do some decorative elements on it if I’m lucky. Silver lining and all that. Oh well. I had to prep more pieces for the lid anyway (which I finally got a design for in my head that should be stable and relatively straightforward to do). Still a bit annoying mind you.

It’s not as annoying, however, as walking to and from work today (and standing on the Luas both ways) and then finding when I got home this evening that I’ve buggered up the leg muscle again, it’s all sore and swollen. Standing, no problem. A step forward or back if I don’t bend the knee too much, that’s more or less okay. Walking from the kitchen to the shed? Sortof like having someone stick in a hypodermic needle into the muscle and then breaking it off so it pokes you at random moments. I think I’m stuck working from home for a few days, this thing is not going to heal if I keep walking a few kilometres a day on it.

Like this:

Like Loading...