So I figured I’d start by playing with the new toy and taking some test cuts.

The blade runs sort-of true. Well, I wasn’t expecting laser levels of perfection here, but the guides really are letting things down. The lower thrust bearing can’t be backed off readily to adjust it so it’s not poking the blade out of true, which is disappointing. And I really can’t run this thing without dust extraction or the whole lower case clogs up and the bearing itself locks up. Well, I knew machinery would counter its speed by increasing the amount of faffing about needed to support it. This is why you usually mount this stuff permanently where you have room to manoeuvre around it. But again, 8’x6′ shed, no room to think, let alone manoeuvre, so we need to make do.

It can’t cut very tight corners, a 2cm radius seems about the most it’s comfortable with. But that could still work. I was playing about making a bandsaw box. They’re not too terrible to do.

Gluing up for these boxes is a bit of a faff mind you.

Well, quite a lot of a faff depending on how badly you design the sodding things. Oh well.

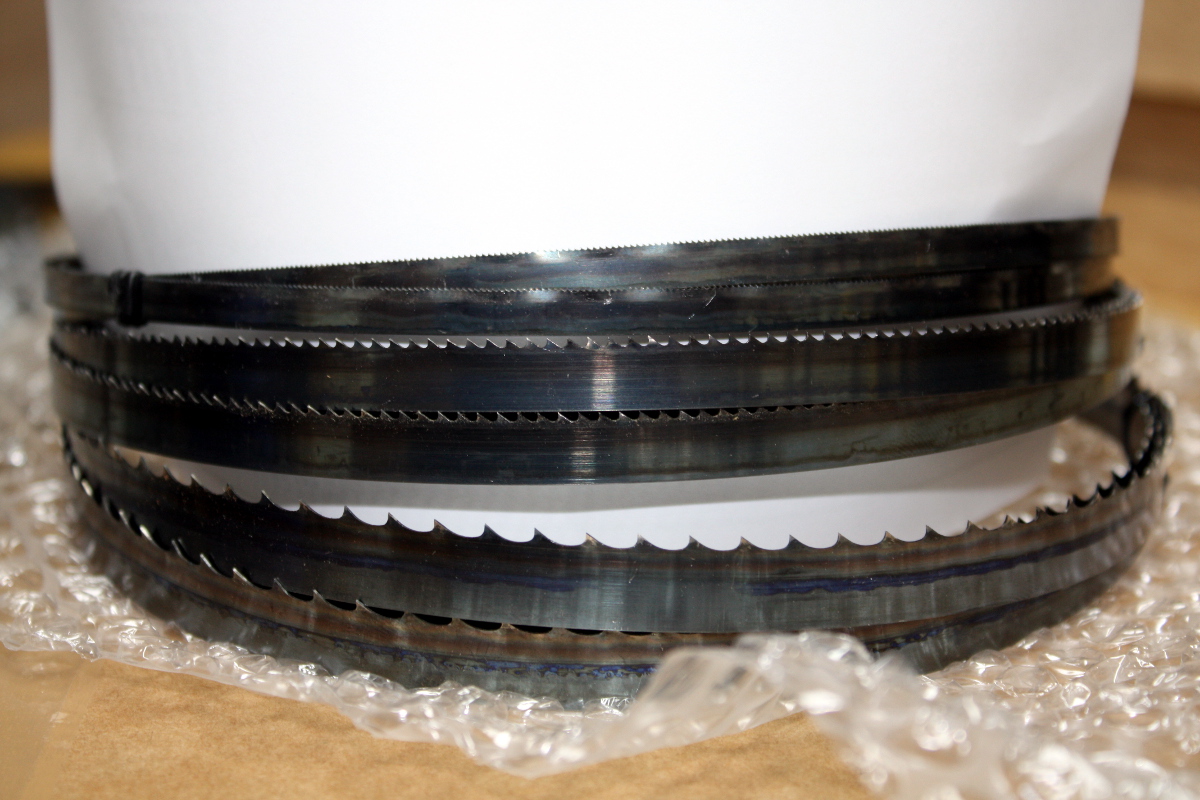

And the three blades I ordered from tuffsaws arrived.

One for very rough work or even small resawing work (but really, you’re talking about resawing stuff that’s at most 70-80mm wide so I’m guessing that’s going to be underused). One slightly more sturdy blade than the one that came with the bandsaw to use for general-purpose stuff, and a very fine-toothed narrow blade to do curving work.

Tuffsaws do have a one-eighth inch blade as well, might try that if the quarter-inch one doesn’t do the job.

Then I carried on with the new project, laying out the rough rips for legs and aprons:

Finally getting to use my new panel gauge in anger. Works quite well for rough layout, but I need to sharpen that pin, it’s not the finest gauge line in the world.

Then I used the new toy to make the rough cuts.

Definitely not up to finished work levels of cleanness, but it cut through inch-thick oak like it was foam, so it saves a bit of work (though the faffing about setting up and cleaning down after using the bandsaw is just a pain in the fundament so handsaws definitely aren’t out of a job yet). I’ll flatten these tomorrow and thickness them, then rip out the individual legs and aprons (there’s two in each board).