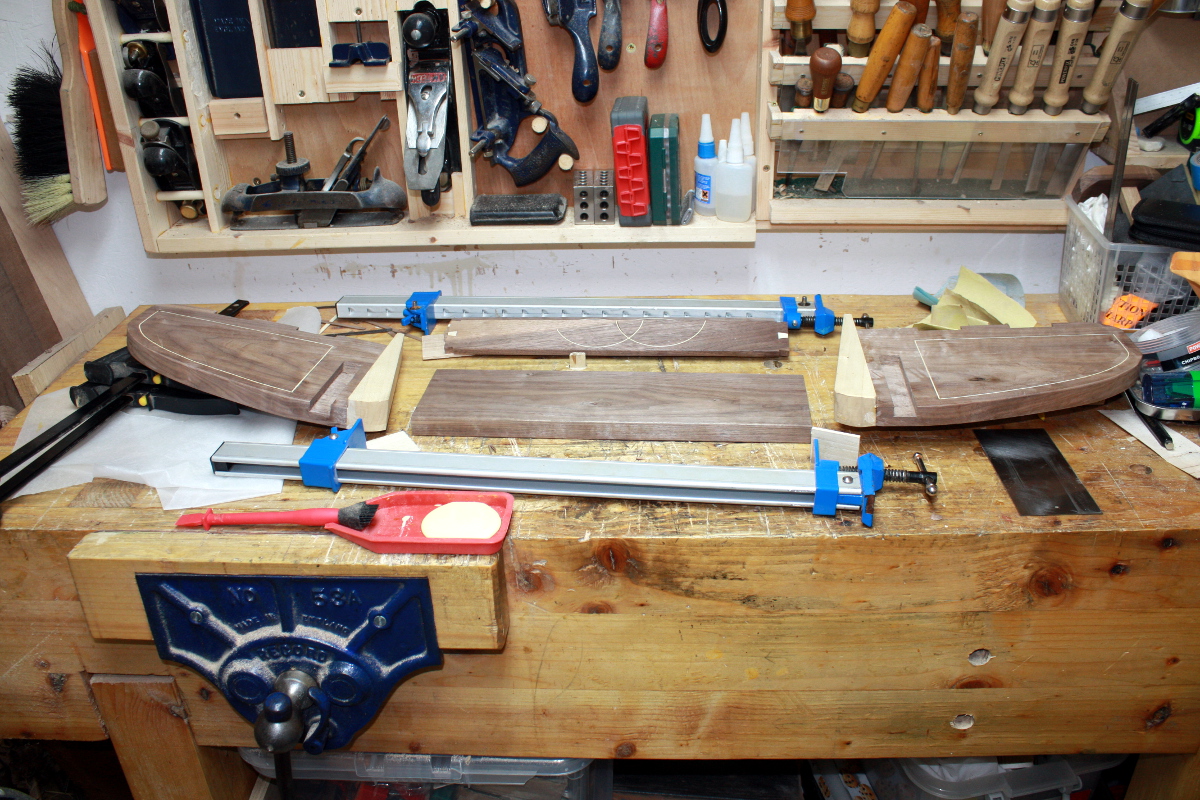

So time to take the shelf out of the clamps and see if it’s okay…

holds breath…

That’s not too bad from the front 🙂

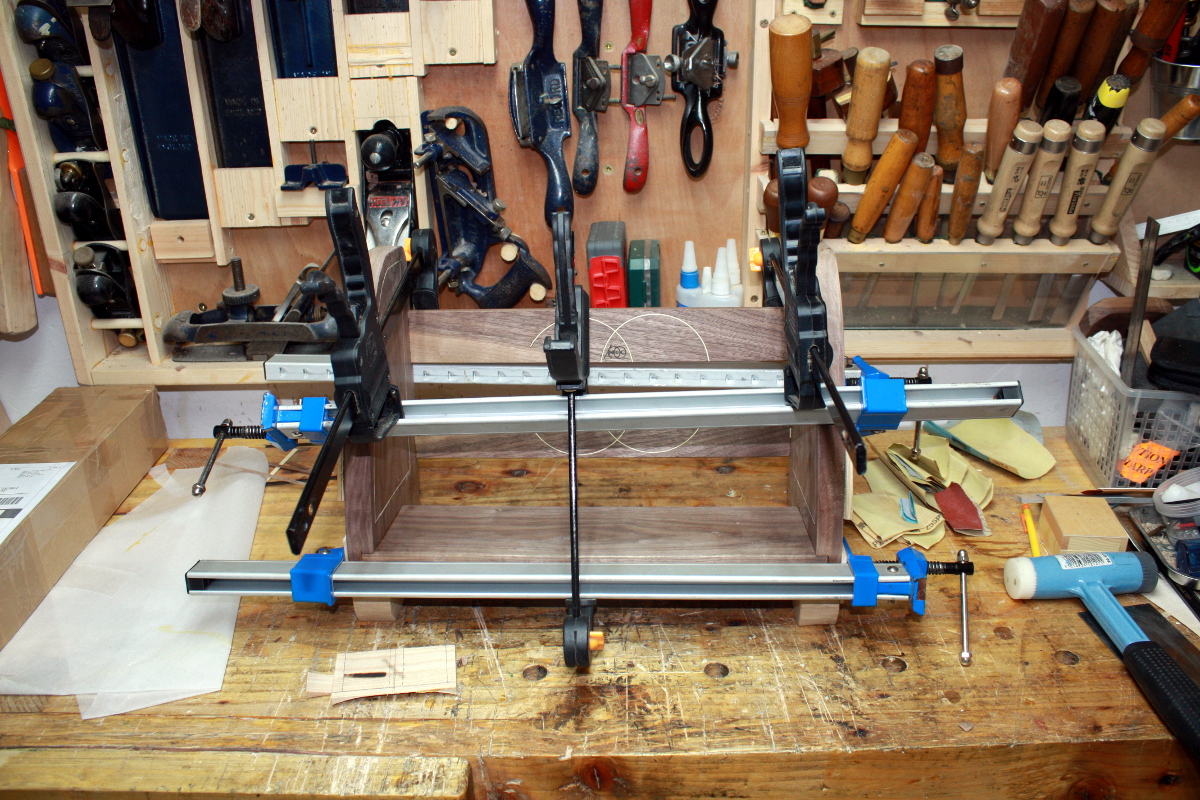

Different story from the back mind…

Urgh those dovetails. There will have to be some remediation work there. At least the white inlay bits worked reasonably well (you just can’t do dovetails from end to edge like that if there’s more than one tail, the short grain on the pin means it always breaks off, so I deliberately broke off the pins and replaced them with some sycamore chunks).

Okay. Time to start finishing. I could keep trying to touch this up for ages and never finish 🙁

Going for a simple finish this time, just some thin coats of osmo and buffing it out.

Magic time 🙂

Little better at the back after some touching up.

That might be nice once the rest of the coats go on…

And then the surprise for the day – Custard over at the UK workshop forums offered to send me some thick sycamore veneer while I was trying to sort out a commercial vendor here for the stuff (the laminated 0.6mm stuff is workable but fiddly as feck and occasionally bits delaminate and you don’t know it till you expose the delamination while trimming off the excess and you now have a double thin white line instead of one slightly thicker line; and it’s hard to thickness properly as well). And the box arrived today. “I’ve thrown in one or two other bits” he said…

2.6kg. In veneer. What the hell is in that box?

Holy shit.

So that small sheaf at the front left over the vice? That’s all I was hoping for. Look at the rest!

Thick ebony and boxwood veneers – boxwood is bloody lovely stuff and with an interesting history and source. And rippled sycamore. Wow. That stuff is stunningly pretty. (If you’ve not seen it before, that plank is perfectly smooth – the lines are figuring, cellular anomalies in that particular part of that particular tree, we don’t quite know what causes it and it’s become very fashionable these days (in the 17th to 18th century it wasn’t so much because it’s not as strong as straight-grained wood, but when veneering was invented you could use stronger wood for the substrate and let the veneer of a figured wood be the final decorative layer).

And the walnut is even prettier when it’s figured like that. And the cherry is figured as well – I’ve not even seen cherry in the flesh before now, I can understand now why it’s so popular for furniture making. It doesn’t come across well in photos (well, in mine anyway) but it’s very very pretty up close.

Custard, the stuff is incredible, you’re a maniac. Thank you!

Oh, and the resawn beech still hasn’t pretzel’d on me…