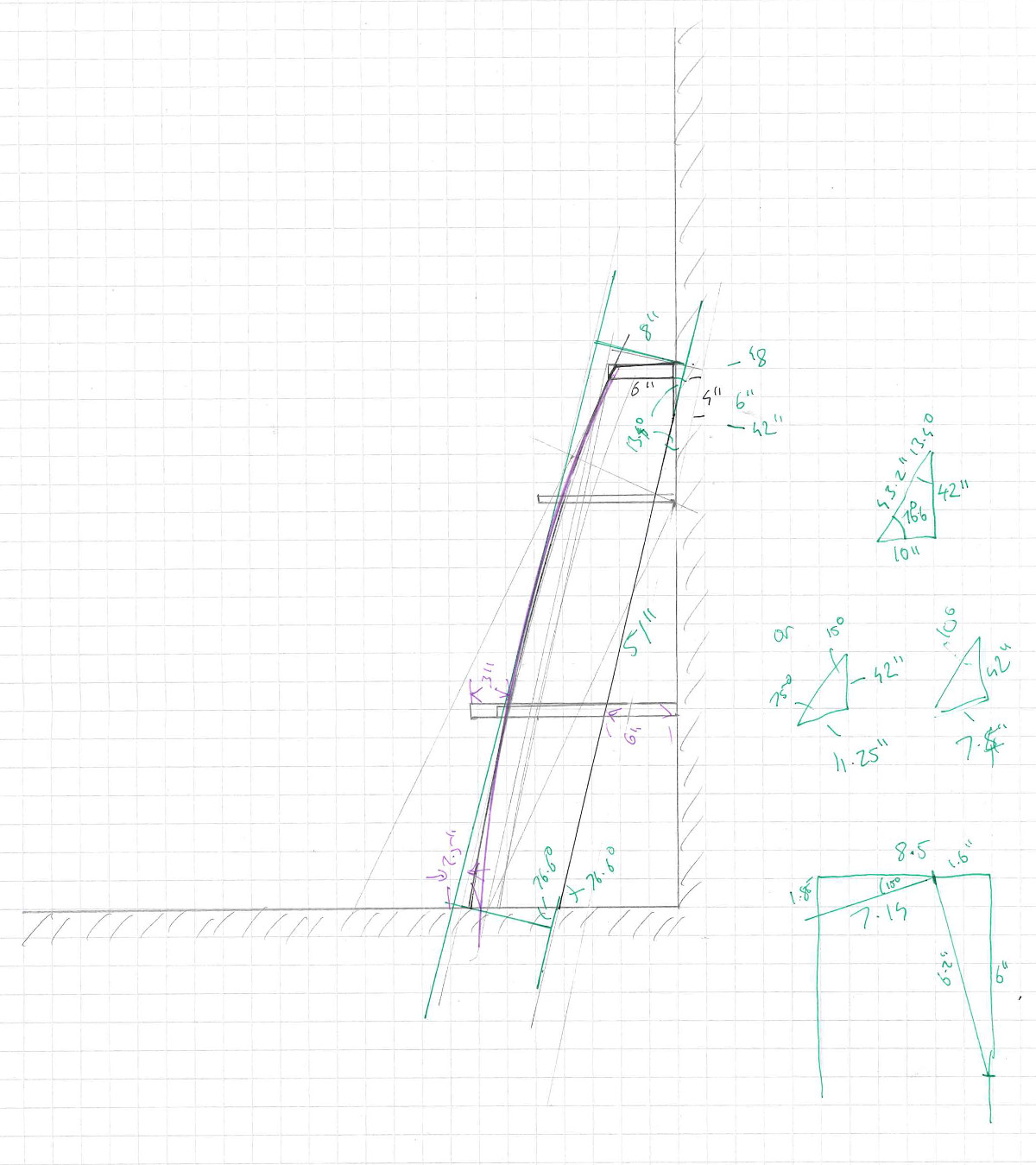

So asking on UKworkshop about that clamping problem I was thinking about with the shelf/desk project led to the conclusion that housing joints won’t work and tapered sliding dovetail joints are the better choice. That will probably mean some router work because of the precision needed – I could probably make a tapered dovetail joint that wouldn’t pull out, but one that would be precise enough to maintain the shelves against racking would be beyond me. So a new router bit, get that router table out of storage and actually assemble it (I basically picked it up in Lidl intending to use parts of it in a proper router table at some point and then just developed a dislike for routers in general 😀 ), and that sorts two of the shelves out; the third gets dovetailed into the top shelf which will also help with racking.

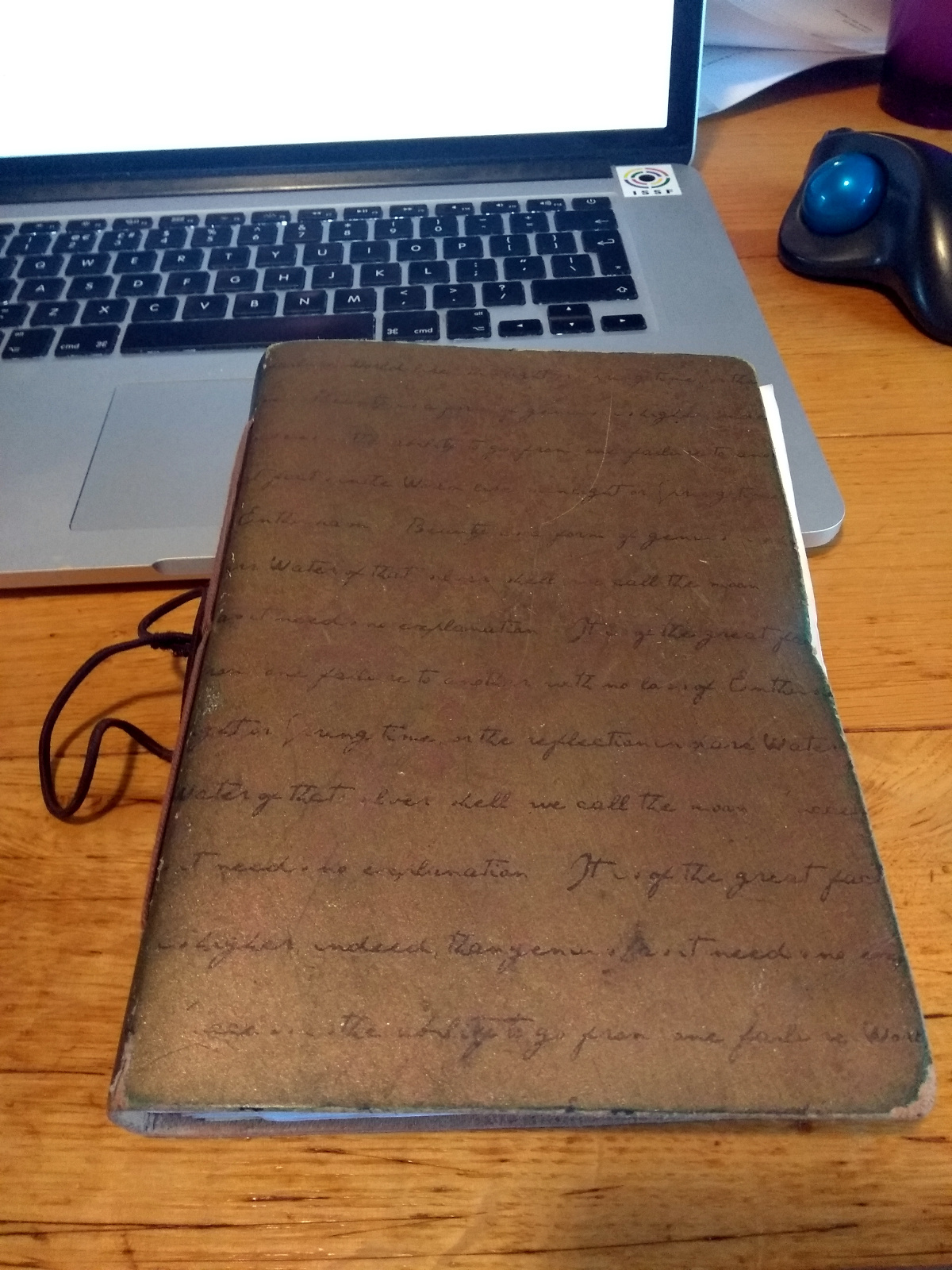

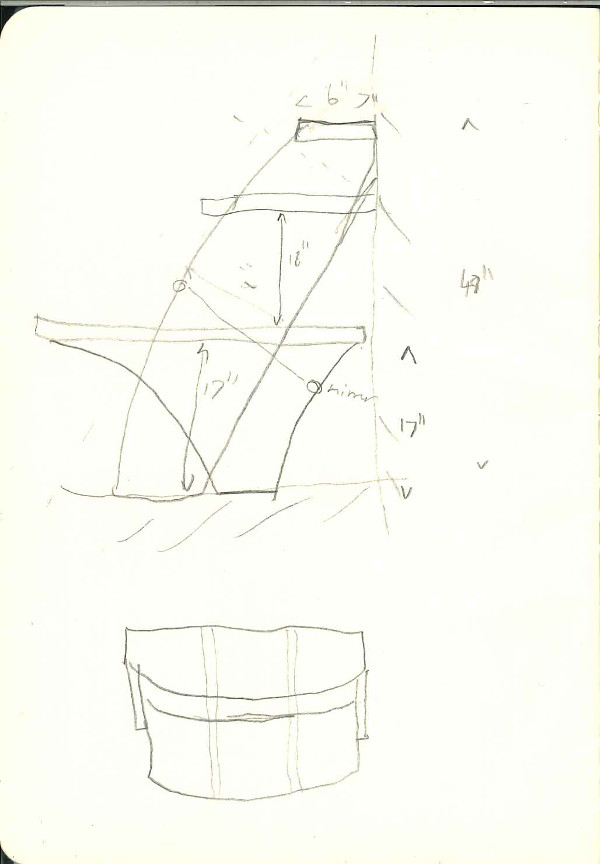

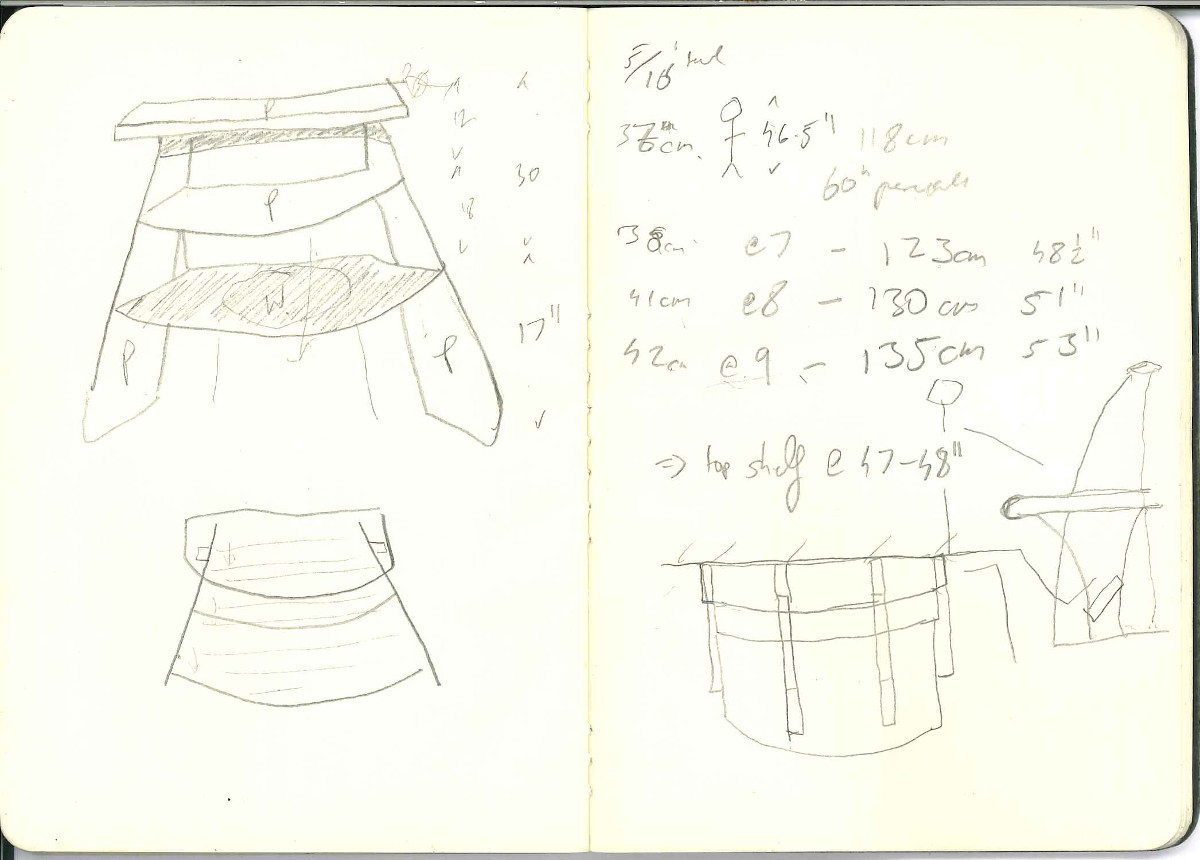

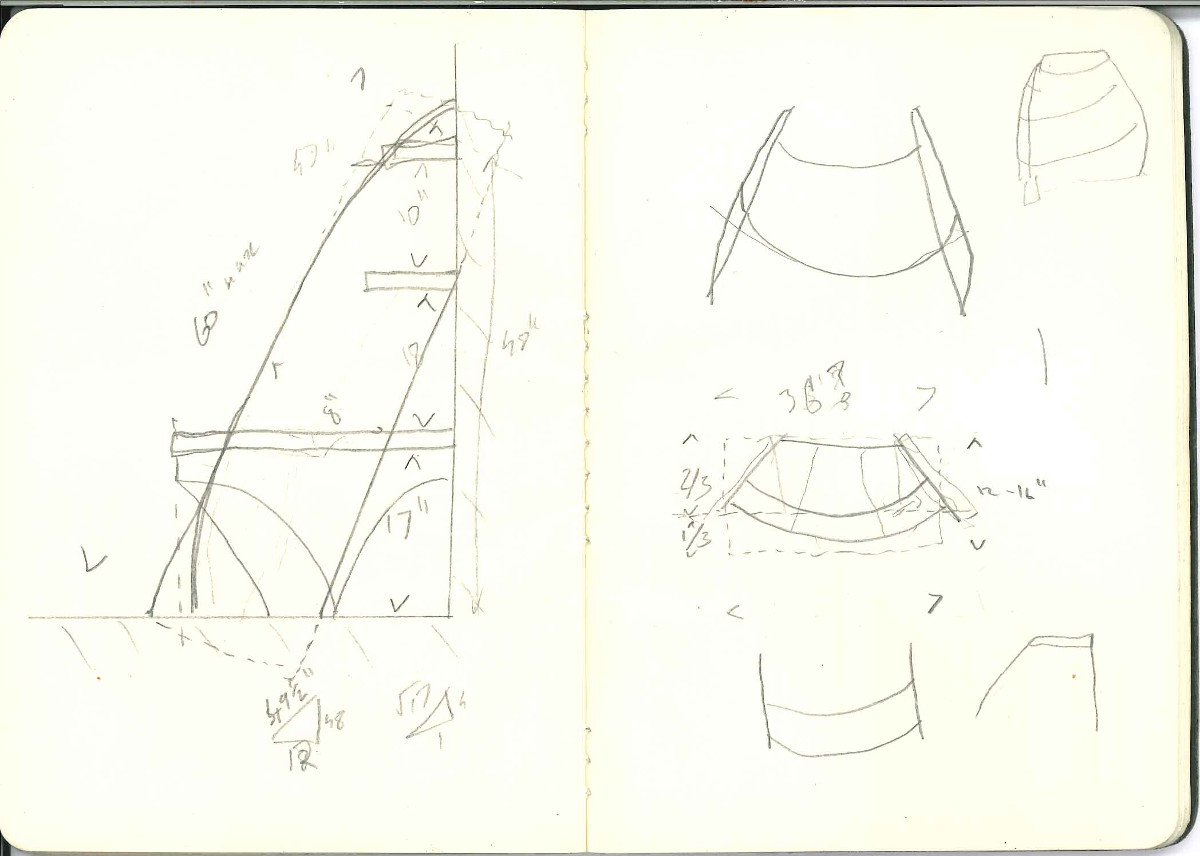

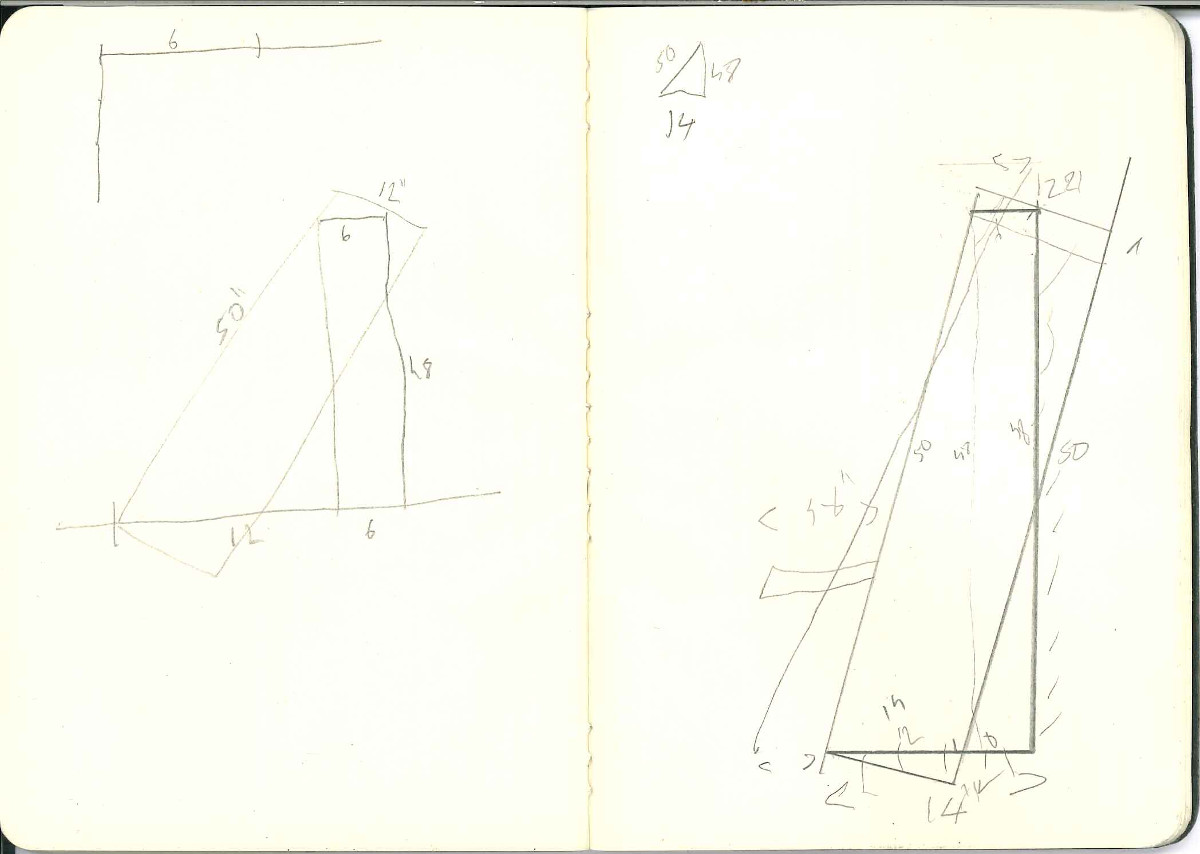

And I keep sketching the idea in my head to try to nail down the bits of it.

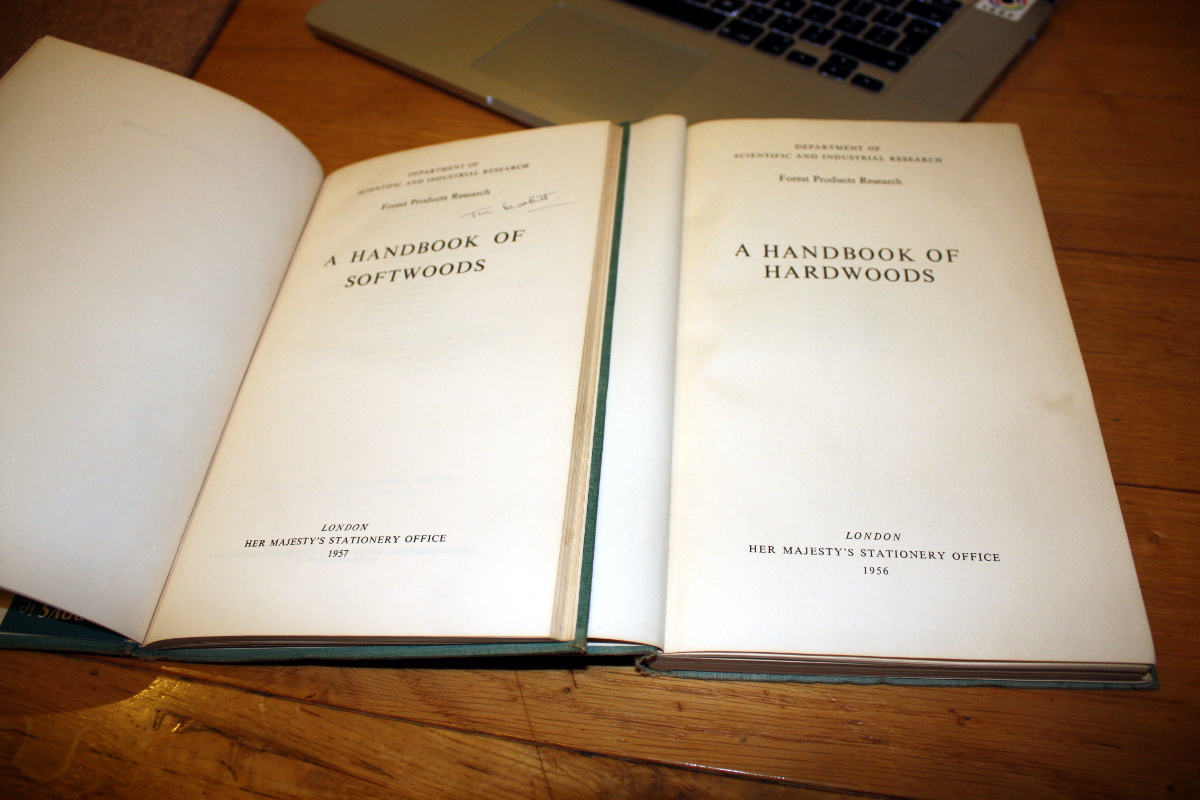

It does feel like I’m trying to squeeze the shape I want out of almost not enough wood; the 8″ wide poplar planks I have might not be wide enough and I might need to do a run to the timber yard for some 12″ wide boards. Which would mean a half-day off work and I’d wind up buying a lot more than one board because if you’re giving up vacation time, you buy in batches. So I’d rather get the pieces out of what I have, but if I can’t, there will be more walnut and poplar and maybe some utile to see what that’s like to work with… see, this is the problem with going to the timber yard 😀

Meanwhile, we’re in a heat wave here and the poplar I have has these green streaks, so I figure I’d let it sunbathe for a few days to get rid of them and get that lovely honey colour poplar gets…

Better than a shop dog 😀

The colour of the wood is easing but it’s not a one-day thing…

Before on the left, after on the right in both cases there (the badge is to get a white balance reference but even that didn’t help much, the direct sunlight just blows the camera away).

I’ll keep doing that for a few days, see if it helps.

I also took the opportunity to see what the side would look like with a 1:1 sketch.

(Yes, we’re reseeding that bit of the lawn, we’re just waiting for the weather to break next week or the seeds wouldn’t have a chance).

That bottom desk shelf really looks too low, I know, but I measured Junior’s knees when he was sitting down and nope, that’s the right height. Kids are just small and the scale looks all wrong 😀

And today, since it was the middle of a heatwave, I had some hardware, tools and a chunk of a tree shipped to the office so I could carry them home…

These quadrant hinges are very definitely *not* brusso hinges 😀 But they will suffice to learn and experiment with. Plus, no damned nails, so hopefully less fiddly.

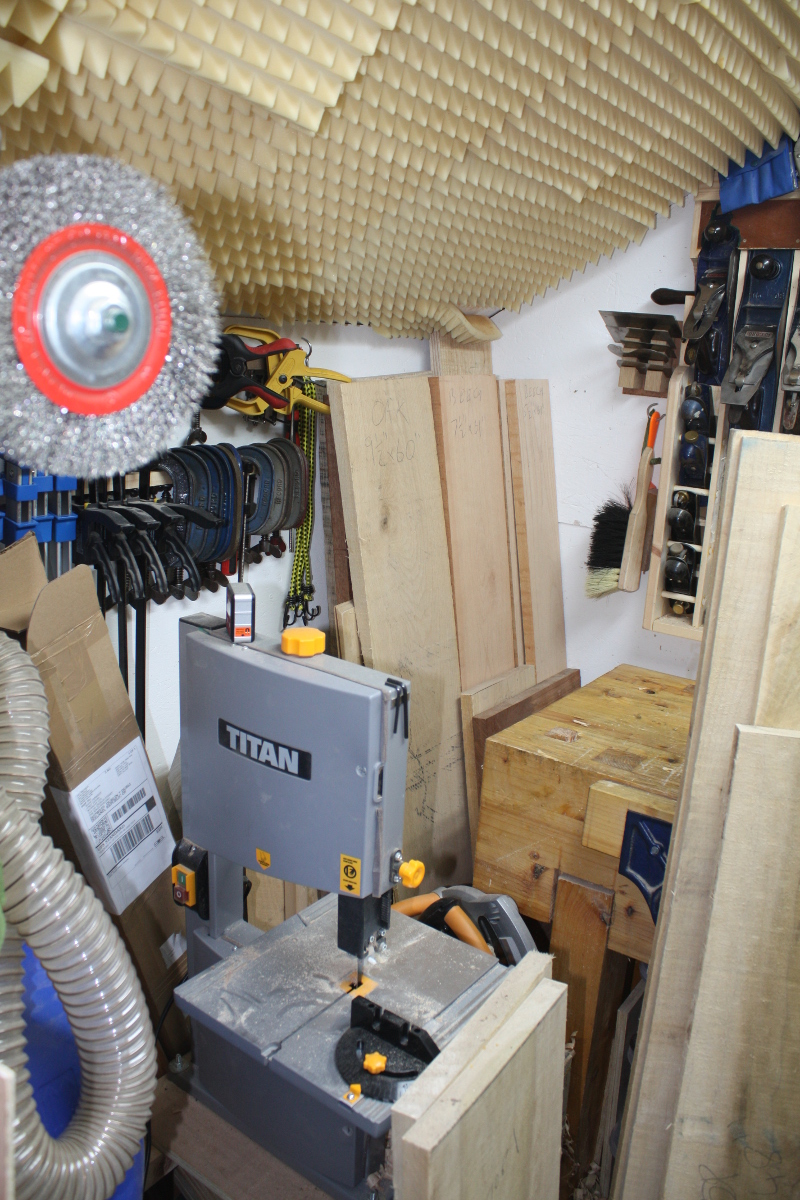

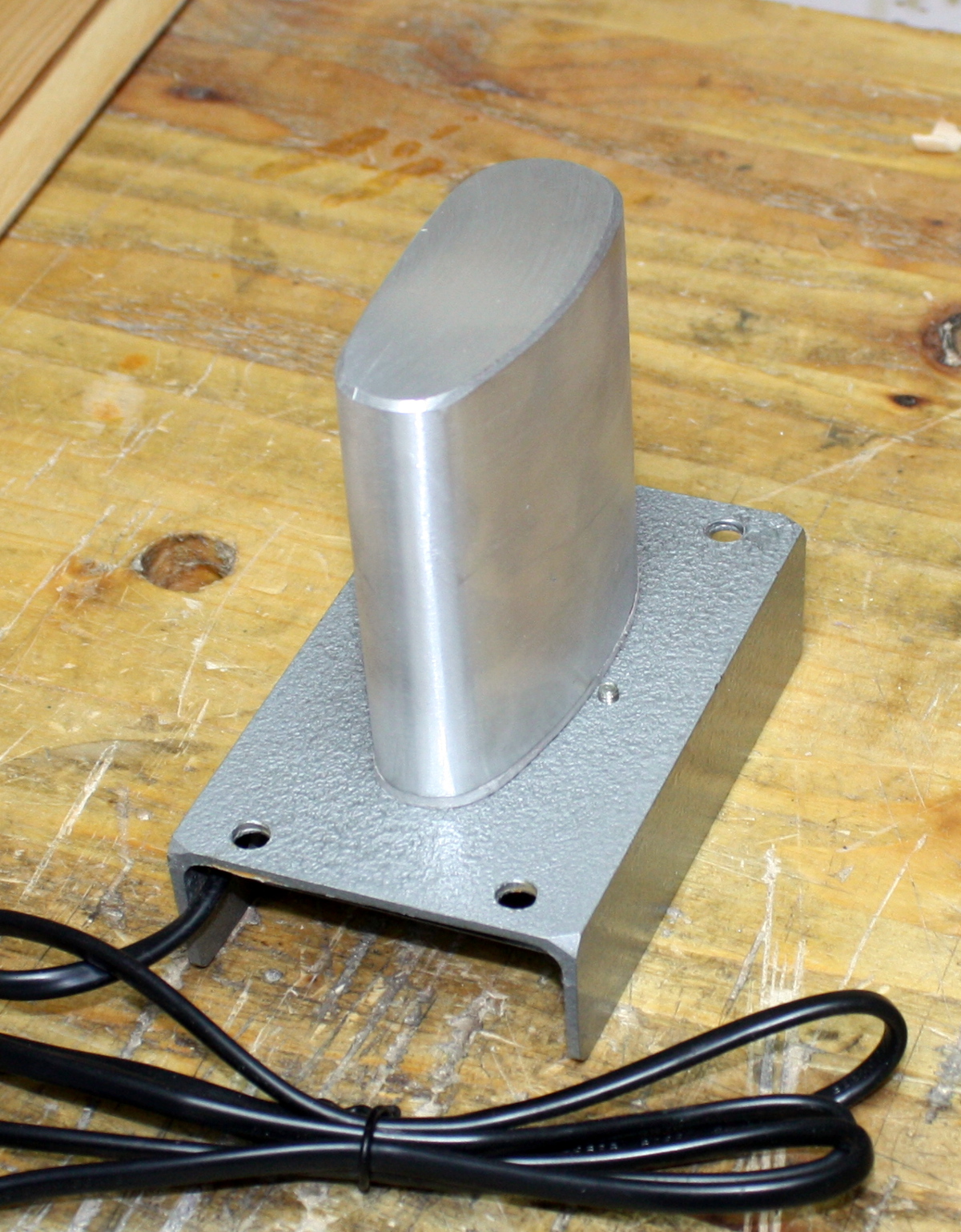

Nobody in the office could identify this 😀

It’s an electric heated bending iron, normally used for making violins. This one’s not temperature controlled, it’s just a PTC resistor in a metal housing that you plug into the mains. The fin bit heats up and then I can use that to bend stringing around sharper corners. Yeah, I could have used a hot air gun, but here’s the thing – in an 8×6 shed, any hot air (at 100C or so) that leaves the gun tends to hit something while still hot enough to damage stuff, especially with foam on the roof for soundproofing, so I decided to go buy this thing (hey, it cost a total of €37 delivered from China via the customs department) instead.

But.

There’s a rule I have for electric stuff you buy off aliexpress (or ebay). If it’s on batteries, it’s probably okay. But if it plugs into the mains, you take the thing apart and check it before it ever goes into a socket, so this got disassembled in the electronics lab and tested for shorts, for the case being connected to the live wire, all that sort of stuff. But no, it seems grand, so out to the shed…

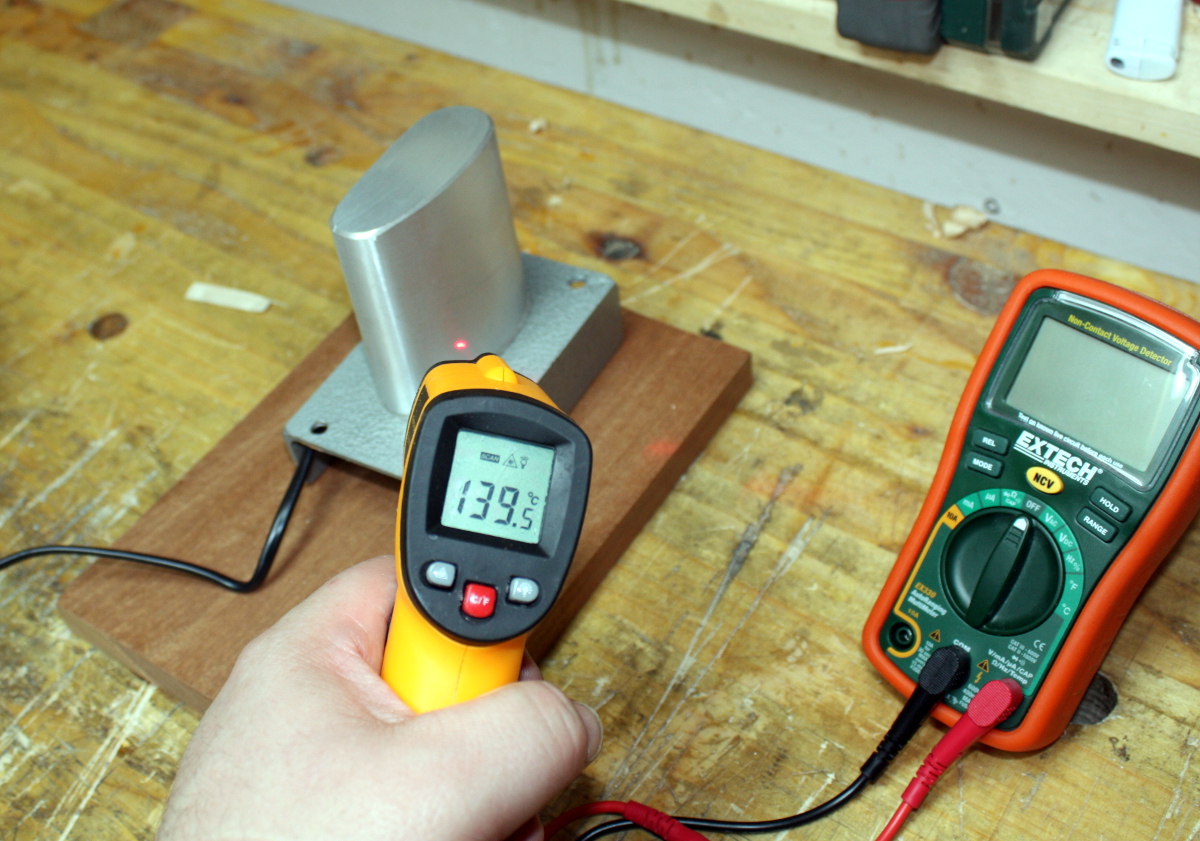

I said it looked grand, not that I trusted it yet 😀 More testing for voltages, waiting to see if the temperature stabilised properly and so forth (that bit of sapele there is to become the base it gets fastened to so I can holdfast it to the bench). All the electrical tests seem okay so far…

The temperature seems a little high mind you, but I think it was made for 110V rather than our 240V. More monitoring needed really and I might want to put some handles on that bit of wood because the fin is not very well isolated thermally from the base…

I worry about the temperature running away too far – if it melted insulation then the case might wind up live and that could be fun. I mean, there’s no ground in the shed really, it’s a wooden floor, but still. Not exactly ideal. Hence, add some handles to the base to pick the thing up and move it about. And maybe some wooden rails along side it to act as hand rests for when I need to steady my hands for particularly delicate bending work.

And what will it be bending? Well, I finally found a commercial source for thick veneers (in this case, 1.4mm thick which is perfect for what I want it for – it’ll get a bit of handplane work to trim it to the thickness of the groove, but with one side of the strip being thinner so it wedges in there).

Some sycamore…

and to compare it against, some maple…

and just for fun, some cedar of lebanon…

That last one is seriously aromatic. I have got to find a source for actual boards of this to use as drawer bottoms, I now know exactly why they used to use this for that purpose. It’s a nice smell, but you know you’re not getting mothholes in your shirts if the drawer is made of this stuff.

Even the bit of hardboard they used to ship this stuff will be of use, if only for drawer bottom material and the like. Happy with that find, now I just have to wait for brexit to screw up the trade rules between here and the UK and for all this wood to become unavailable again. Hell, it might be an idea to stockpile, the way things look to be going…

(You laugh, but you know how house prices in Ireland are rising faster than a SpaceX launch? And you know how we use timber for building houses in everything from making doors and stairs to roof eaves, scaffolding and so on? That timber all comes from the UK because Irish timber yards are too small to buy on the continent because we’re just not that big a country – we have 4 million people, they have 50, and they build more so they buy wood by the hundreds of tons and we buy off their yards and ship it to here. Brexit is going to throw a huge spanner in that, stuff will either have to come from the continent meaning higher purchase prices, higher logistics cost and so on; or yards here will have to buy stuff from UK yards at enormously higher prices. And all that gets passed on to the final house price here. Stockpiling doesn’t seem so ridiculous now, does it, eh?)