Well, that didn’t go as well as I’d hoped.

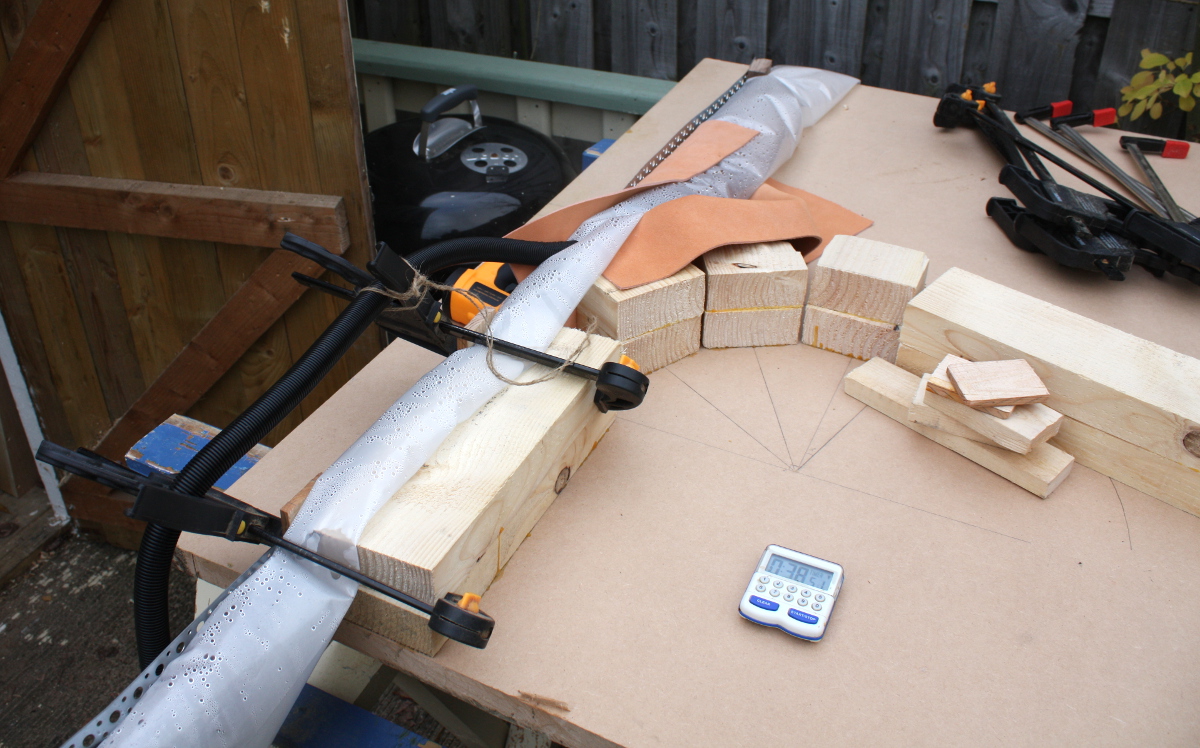

The steaming jig was ready, the drying form was ready. all the shopping and other stuff was done yesterday, so this morning I finished planing up the two candidates for uprights so they matched perfectly in size, rigged up a wide compression strap from three narrower ones (thanks addresspal for losing my order for a wider one) and then into the plastic tubing one went, and in went the tube from the wallpaper stripper and away we went.

It got steaming pretty quickly, but it was a rather chilly breezy day today (down around 10 degrees or so air temperature at this point) which was depressing the temperature a bit every time the wind breathed wrong.

Some insulation was needed, so the airing cupboard got raided for towels.

And then it was just a case of waiting while the wood steamed, and refilling the tank of the wallpaper stripper about 45 minutes in before it ran out.

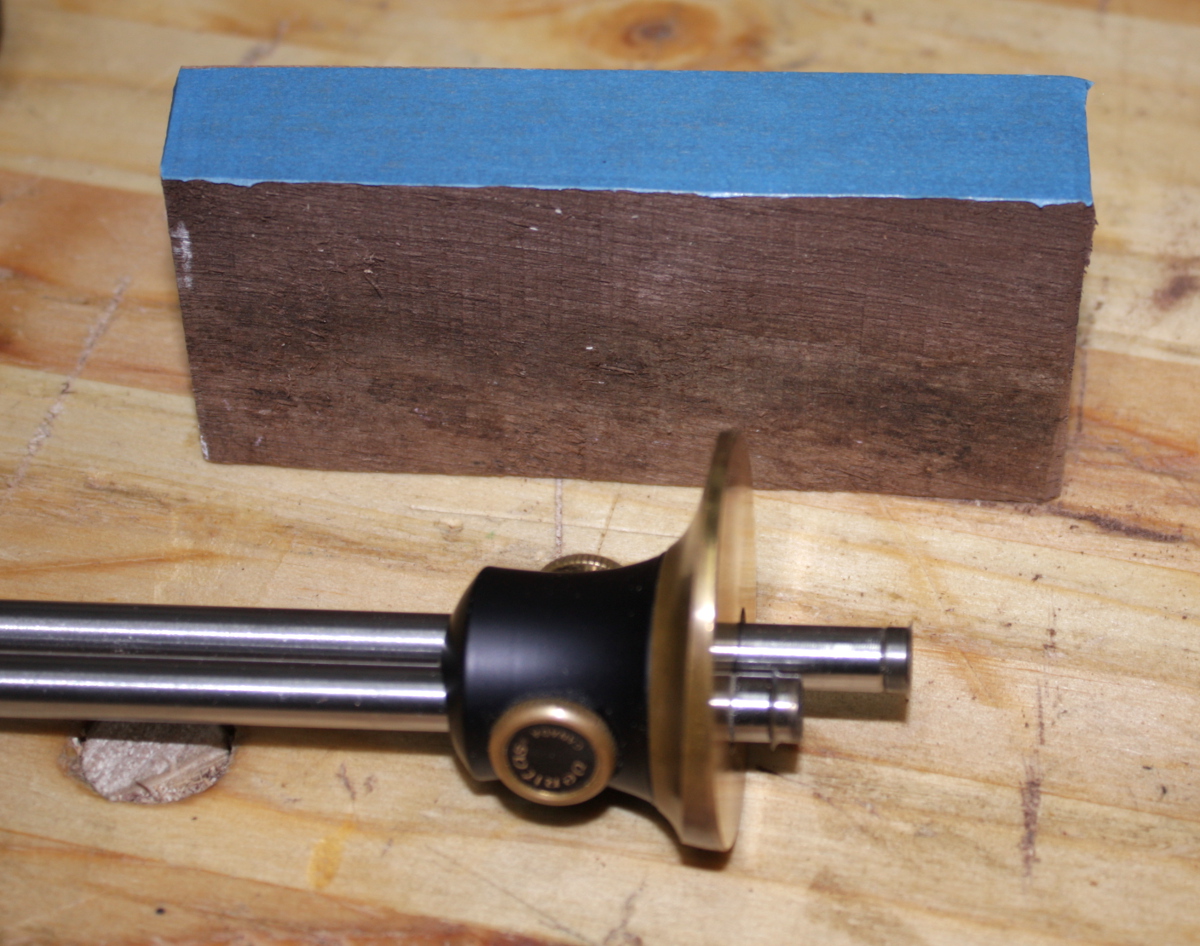

While waiting, I worked on the platform for the mattress. First up, double-check that the components matched in size.

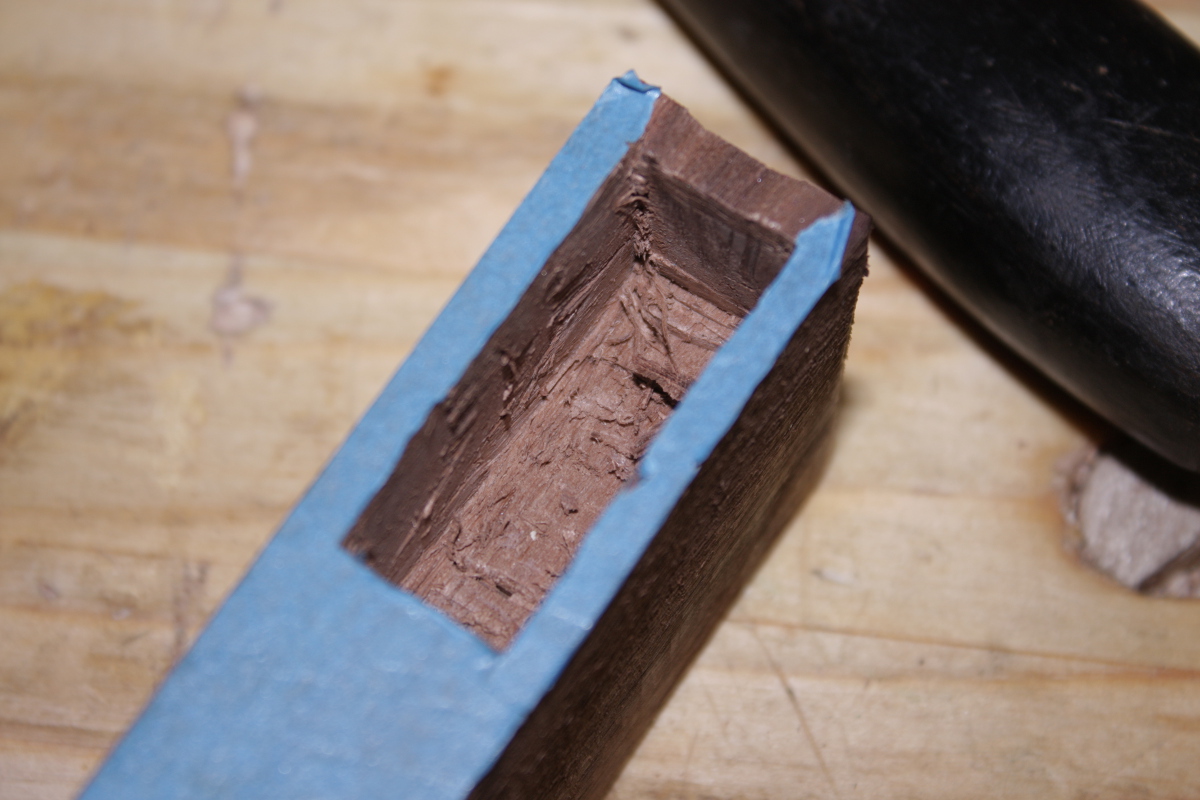

Yup, all good. Then took the crossmembers, left the middle one aside for now, cut the other two shorter by about an inch, marked up for a half-inch wide mortice and tenon joint at each corner, and got chopping and sawing. I tried that method where you clamp a board in the face vice and put the board you’re morticing on the benchtop and clamp that to the board in the vice, and it works better than the method where you clamp the moticee board in the vice (morticee board? the thing you’re chopping holes in).

It didn’t turn out too badly. I’m tempted to drawbore these, or at least pin them, but I think the glue will hold them when I glue up. I checked the fit against the mattress again at this point and yup, it’s a solid match. Grand.

Now the downer. Continue reading →