Small delay getting to the shed on Sunday.

Well. It’s a kind of woodwork.

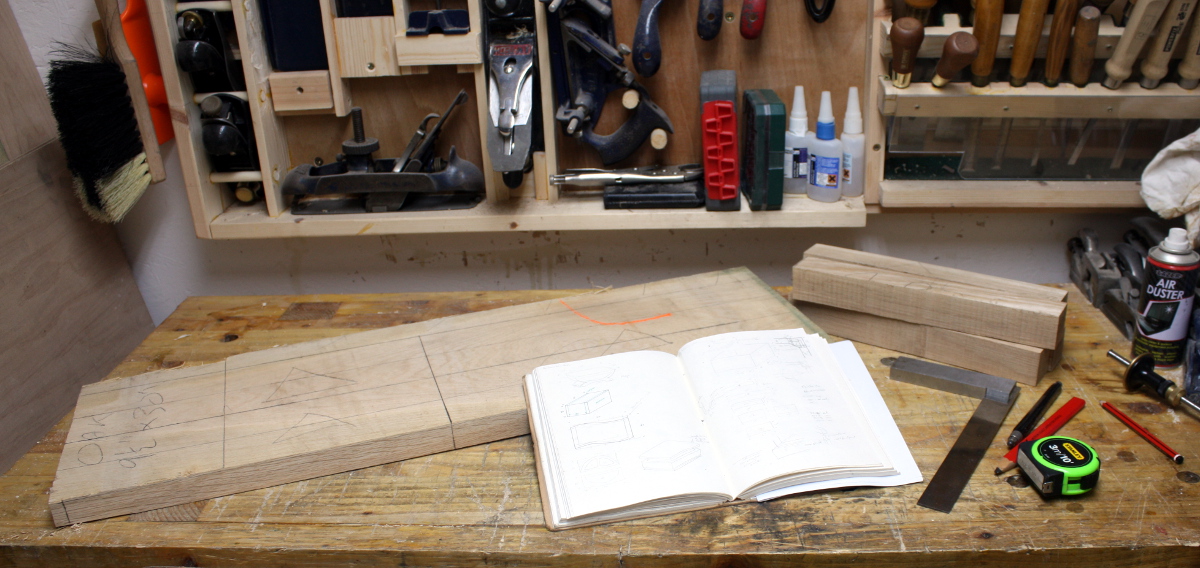

Anyway, that evening, at around -3C in the evening. off to the shed. There were feet to shape.

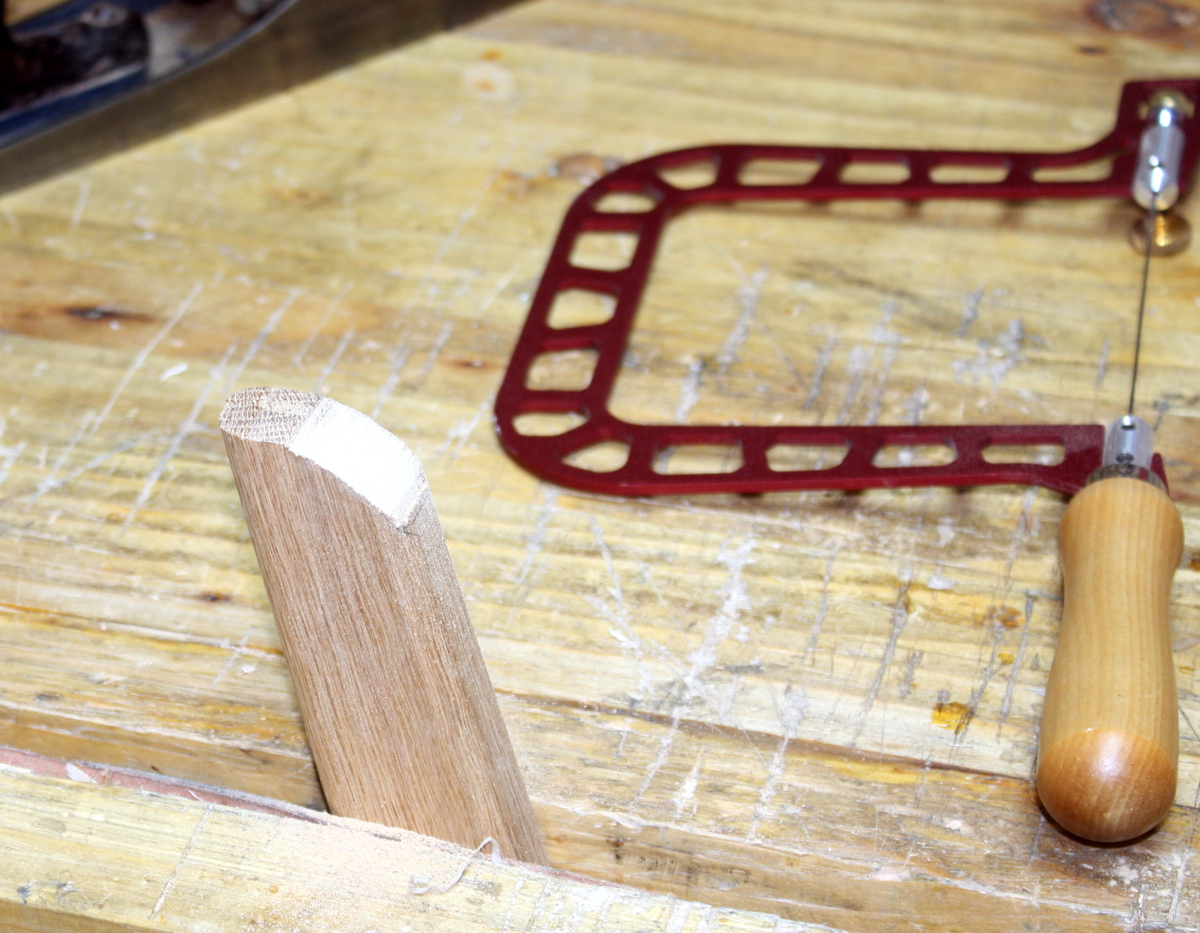

I know, I know, Richard Maguire does it with a chisel. He also has enough room in his workshop to stand at either end of this bench. Anyway, the fretsaw was in need of exercise. So once the curve was cut, I used the spokeshave and a paring chisel to clean it up and cut a chamfer around the feet.

Dainty.

And they don’t rock, happily. And I’d put in a bullnose profile on the front sides using then #5 and #4 and a cabinet scraper.

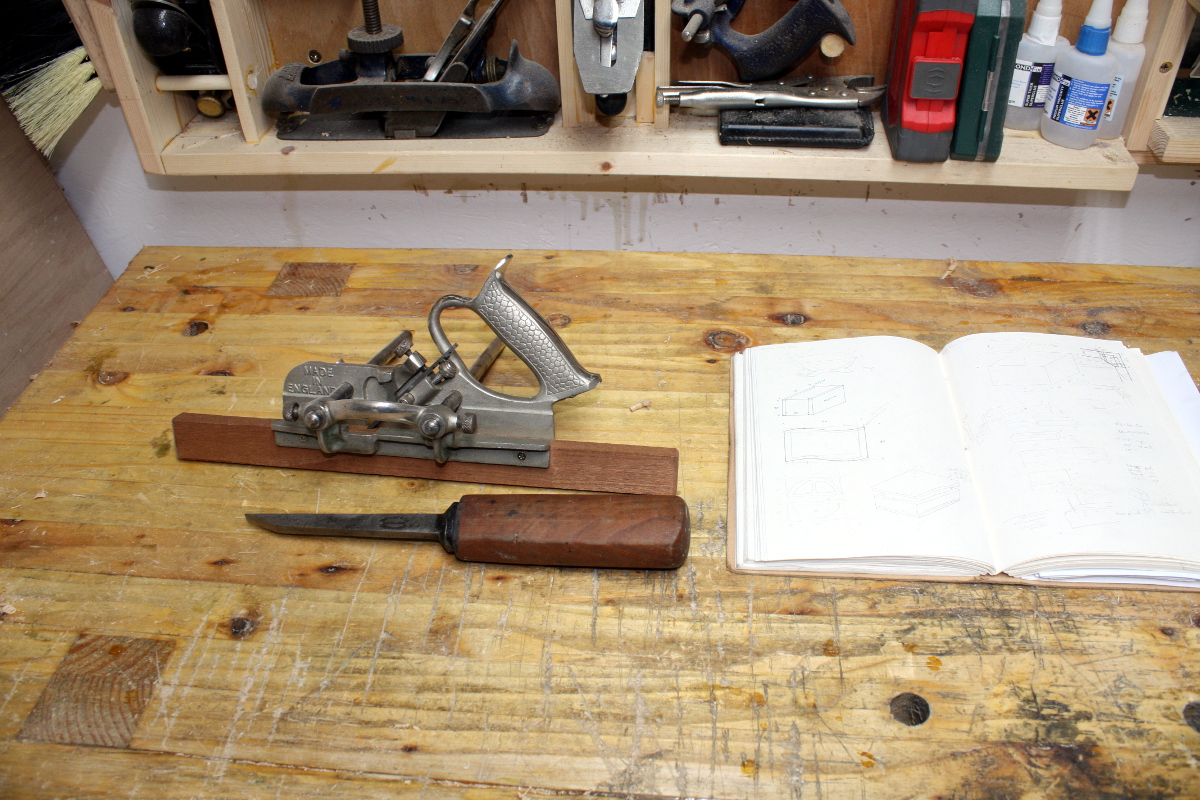

Unfortunately, that meant it was time for the job I was putting off. Out with sid…

Before:

After:

Also after:

If anyone ever asks if it hurts to cut yourself with a chisel, the honest answer is no, they’re so sharp you don’t notice you’ve done it till later. Slipping with the scrub plane and slamming your hand full force into the dull edge of a planed-square board with a metal plane behind it, now that hurts.

Still though. Pretty.

Okay, time to set it on fire.

No, seriously.

There. Nice and discreet.

Then back upright for the last time.

And one good stare later (and a few minutes cleaning up the stuff I spotted with the cabinet scraper), it was time for disassembly for the finish.

For the top, it’s pretty simple. I chose the grain for the top and planed it to look nice, so that just has to get shown off. It’s getting a few coats (probably three) of osmo:

Just ragging on and sanding back when dry with 600 grit paper (it’s resting on the four bolts in the inserts there, I haven’t figured out how to levitate wood yet).

Nice rich colour when it’s wet, we’ll see how it holds up when dry. Then flip over and apply the first coat to the top nice and carefully.

The legs are getting a slightly different treatment – they got sanded down with 240 grit to open the pores from the plane finish they had, and then painted with oak shaving tea (collect two handfuls of oak shavings off the floor, boil with some water in a saucepan and then simmer for ten-twenty minutes, put water and shavings in a jar when cool):

The idea is that the liquid is now very high in tannic acid without having to go on ebay and buy tannic acid crystals. Paint that on the oak and you raise the tannic acid levels and raise the grain at the same time. So on monday night, I sanded down the legs with 240 again as they had dried (not bad going given that the shed hit -5C overnight) until they felt dry and smooth again and then repeated the oak shaving tree routine. I’ll sand them down again tomorrow and reapply the oak tea for the third time but this time I’ll just let them dry for a half-hour or so until the wood is damp but not wet; and then I’ll apply the other half of the magic, a solution of vinegar that has dissolved steel wool over the last week. The iron and the tannic acid will react and ebonise the oak. The end result should look like this if it all works:

In the meantime, something arrived in the post…

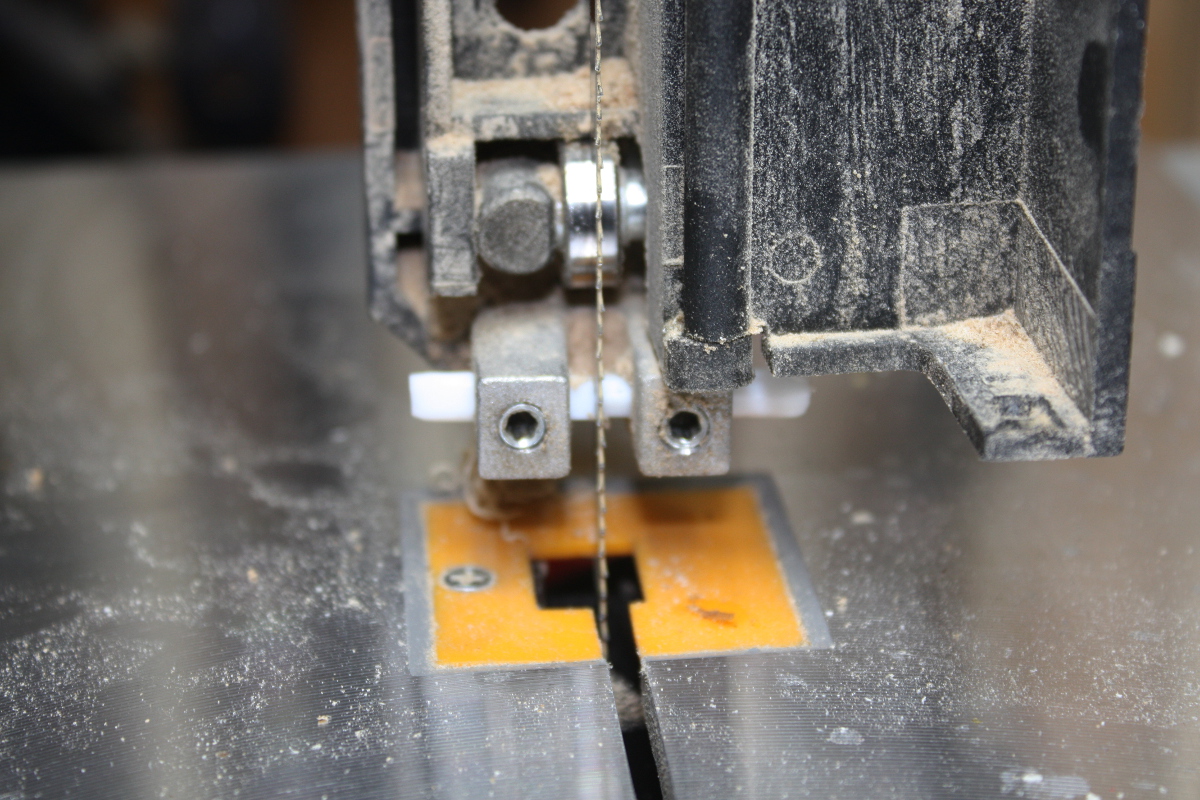

New bearings to use as thrust bearings in the bandsaw with a larger blade size. Gotta love the lego-parts aspect of mechanical engineering…

…downhill on a wet slope towards a brick wall while blindfolded.

…downhill on a wet slope towards a brick wall while blindfolded.