So this:

is a shooting board (this one’s from Popular Woodworking, mine’s not as neat). Idea’s simple – for thinish boards (once you get up to an inch thick, you start just holding it in the vice and running a block or bench plane across it), you feed the board into the plane which is on its side and it will true up the end so it’s exactly 90 degrees to both faces and edges. Which is handy for making things that don’t look like they were drawn by Escher while drunk. Problem is, most of my planes don’t have big sides – they’re the traditional bailey pattern and have rounded cheeks:

Which works, but it is a bit tippy. And the sides aren’t quite 90 degrees to the sole either, they’re a degree or so off. No problem most of the time, but for shooting board use, it’s a pain. Plus you have to use the lateral adjuster to get the blade exactly vertical and then use it again when you finish using the shooting board and so on. There are specialist planes made for this sort of thing, like the Veritas one:

But that’s about three hundred euro, so no 😀

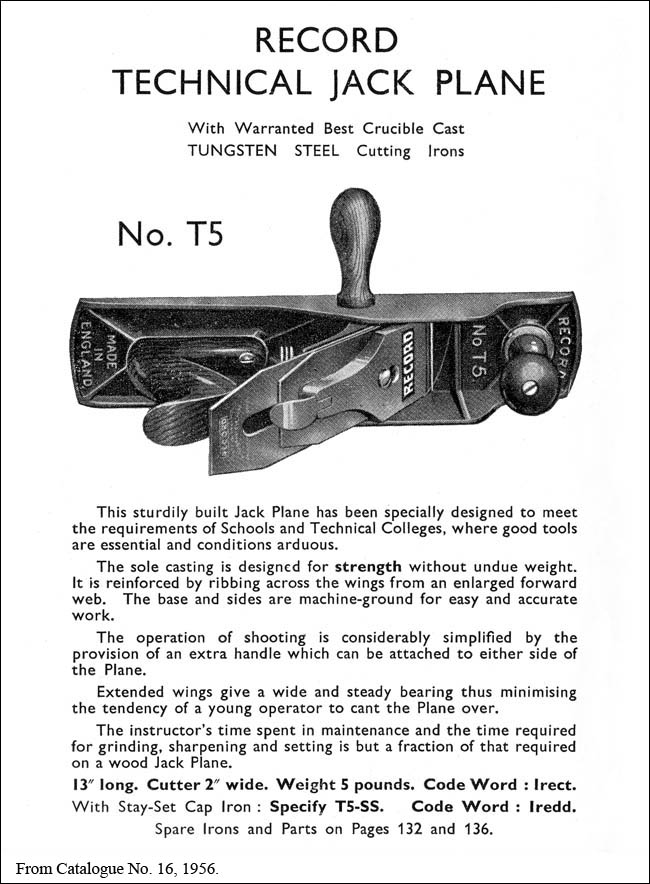

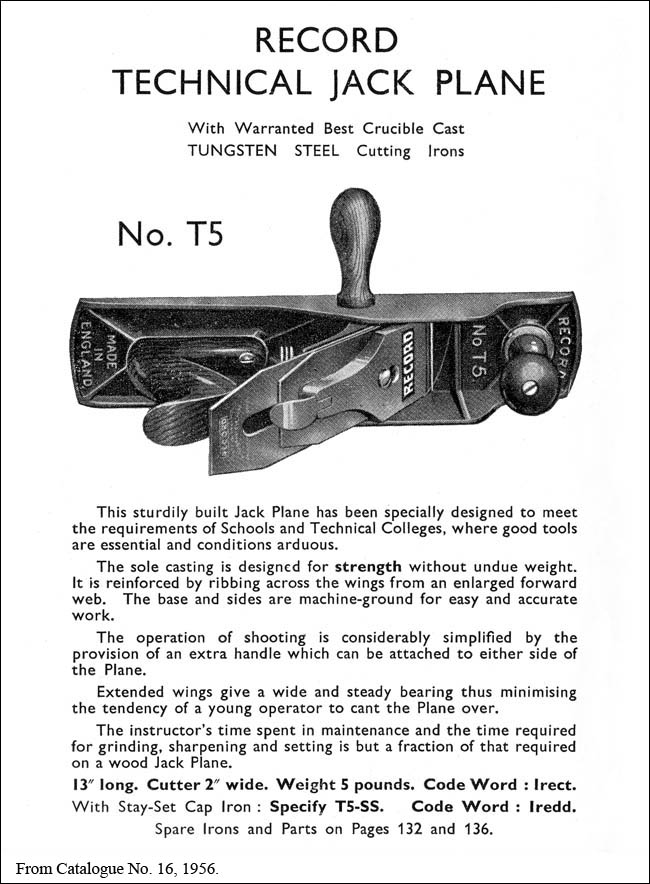

However, Record did make a plane that was intended for use in schools, called the T5 (for Technical apparently):

(that photo from recordhandplanes.com btw, which is an excellent reference for these things)

So I’d been keeping an eye out for a T5 in decent nick on ebay and recently saw one and won the auction for it (by about 51 pence, cheekily) for a sixth the price of the veritas, and today it arrived:

It’s in marvellous condition, perfect paint job, perfect varnish on the handles, shiny brass, damn near ready to use out of the box (the blade needs sharpening, but that’s normal). It’s probably in better shape than any of my other planes, except a #4 that’s also immaculate (I don’t think anyone ever used that #4, it just got displayed and then sold 60 years later). If you’re looking for this sort of stuff, I’d recommend the ebay seller I bought this from, lovely chap to deal with and excellent quality stuff.

But enough on the new toy (which will be getting a workout with the slats for the crib I suspect), on to the day’s work, and today was to finish fettling the back panel. This proved fiddly, eventually turning out to be off-square because of an unevenness in the groove for the panel in the bottom rail because the fence of the #44 plane was riding on the benchtop. But I got it square and most of the gaps were gone or down to less than half a millimetre. The idea of drawboring these grows more and more attractive (that block of white wood behind the T5 above in those photos is an offcut I got a while back which is a lovely contrasting colour and is perfectly straight-grained, perfect for making small dowel pins with. I’ll test it on some walnut off-cuts and see how it goes.

With that done, I cut the front panel using the back panel as a template, cut the rebate in the back and the bevel on the front, making the rebate a bit deeper on this one because I’d like the center of the panel to be lower than the rails or at least level with them as it’ll be butted up against the side of the bed.

Then on to the frames, again cutting the long rails using the back rails as a template and then marking the mortices onto the curved front rails from the back legs. More mortice chopping and tenon cutting and cleanup and fettling followed.

By the way, when cleaning up tenons with a chisel, don’t blink…

Those things are just plain unpleasant…

Anyway, some fitting and checking and fettling later, with a lot more stress this time because a mistake with the curved rails would be difficult to repair, and the front frame was done… okay, minus the grooves for the panel so it’s not fully assembled but here we are….

Heh. Elephant-y. Lets stand it up…

Er. Hm. This was a problem I had not considered. That is literally touching the ceiling on both sides and sitting flat on the bench. The foam isn’t holding it up – it’s actually in compression like a spring between bench and table. Assembly… may be challenging. I may need to do it outside the shed, and the weather is not forecast to be great (as in, driving rain and gale force winds and freezing temperatures, none of which react well with hide glue, walnut, ash or humans).

Gonna need a bigger shed.

Like this:

Like Loading...