So the early start plan kinda went to pot because of other duties, but I did manage to get to woodies and get another tin of the willow colour of paint to do the second coat on the shed. And then, annoyingly, got the second coat out of the remainder of the first tin. Gah. Oh well, I’ll find something for it. Meanwhile the shed’s looking okay, but I didn’t manage to get the first coat of the cream colour on it, so that might make getting everything finished tomorrow a bit of fun.

Can’t say that it looks like a massive difference with the second coat, especially as the colour darkens very noticeably on drying, but this stuff really does need the second coat when you look at it close up.

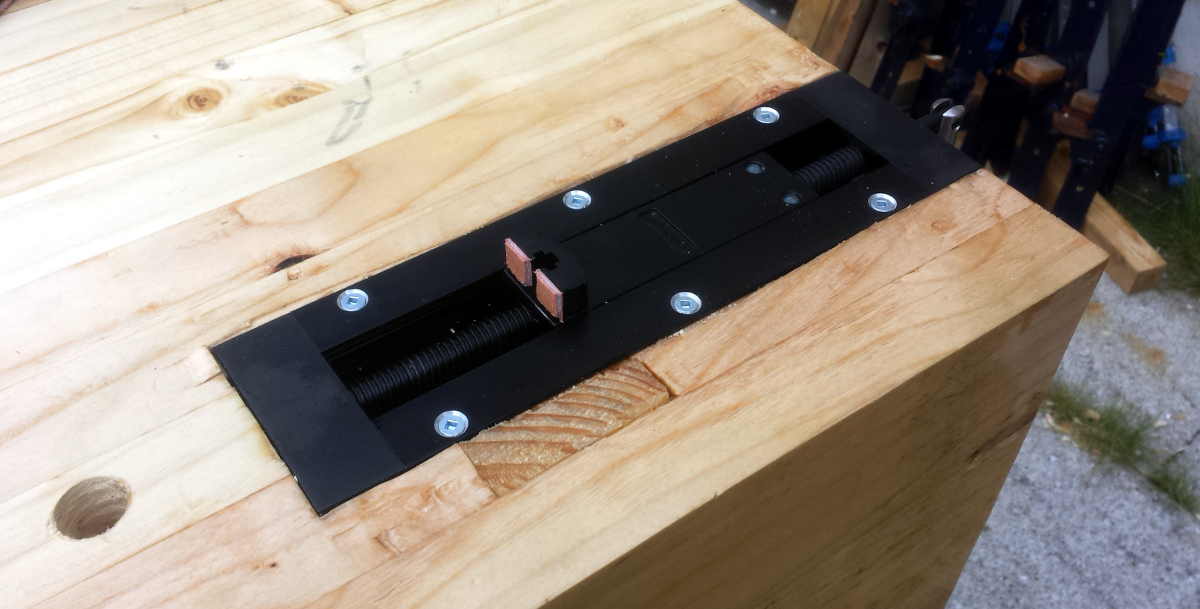

Then on to getting the cheese press done. I picked up the needed bits of threaded rod and such at woodies while getting the paint.

The threaded rod will get cut into 1′ long sections to form the two side supports and the main screw and the various washers and nuts will secure it (the hooks are for my bench brush which is in need of a better home than hanging on the quick-release of the vice).

The more difficult part of this has been getting a 2×2 chunk of wood down to something that vaguely looks like a handle if you squint and are blind. I was able to saw out a big chunk of the waste, and carve the basic shape very roughly with the gouges, but trying to get it even close to smooth was being a pain so out came the spokeshave, which promptly tore the crap out of the surface no matter how I twiddled with it. So I took a tip from Richard Maguire’s spoon rack series, took off the adjustment knobs completely, and set it by keeping the base flat on the bench and letting gravity put the blade in contact with the bench, then tightening the clamping screw. And it worked like a charm. It went from biting and skipping and destroying the face of the wood to looking like an actual woodworking tool being used by someone who was competent. Not sure how it managed that last bit, but I wasn’t complaining much. Before long I had an ugly lump-shaped chunk of tree branch and figured I should stop before I broke it too badly.

Some butterfly nuts on the two side supports to cinch the crossbar on to the top of the cheese vessel, and a chunk of wood on the bottom of the screw to push against a plate in the cheese vessel and that’s your cheese press, more or less. First, some nuts needed epoxying and there was a small void to fill on the face of the board.

Tomorrow I’ll clean up the boards and get them flat and shellac them, add the block on the end of the screw and I think that’ll be it finished. It’s not a very fancy thing after all. I’d like to put some springs on the side bits of threaded rod, but I couldn’t find any. Oh well, easy retrofit.

Of course, that last spokeshave session had a casualty…

I know I said I’d make a hardwood vice face later on, but I think it might be sooner than I thought. I re-screwed it on, but I don’t want to glue it and I’m not sure those two screws are going to last. I’ll have to think about this one.

First though, on to resawing ash for slats. One or two of the resawing boards tonight were pains in the fundament with the blade wandering out of nowhere, but I was able to use the disston to get the line back on track and finish the cut without losing a board. Which let me write a very nice number indeed…

20 slats out of three boards, with another three definitely unusable and another one as a very marginal call (ie. use it if we really need just one). That’s all the original plan called for. I don’t doubt I might find I need another two or four more, but I’ll try not to 😀

In case anyone was wondering, yes, you can resaw 1″ thick 8″ wide ash boards by hand, and it’s not actually the most strenuous job in the world… but it’s not a lot of fun either really, and it can be finicky keeping the blade from wandering. As soon as I’m able to house it, I’m going to get a bandsaw.

Now, for the coming week, it’s planing in the thicknessing jig to get those 20 slats all down to size…