May day bank holiday weekend. Going to try to finish up the box. First up, the lid, which I already have a piece prepped for:

Also, bought two new tools, this time off aliexpress.com rather than ebay.co.uk. You wouldn’t think of aliexpress for hand woodworking tools, but there are a few…

A clone of the shinwa saddle mitre square, and…

A marking gauge. Works like a normal marking gauge on the right hand side there; on the left hand side, you have two contact points that rotate, so you can mark a line “parallel” to a curved edge. Neat.

Oh, and I want to try that resin experiment again, but this time seal the oak grain so the resin can’t wick into it.

The lid’s been sitting around for a while. It had twisted very slightly. Fixed that with a few #04 swipes and then took the #80 to the surface to clean it up nicely, with a few focussed bits from the cabinet scraper. With that done…

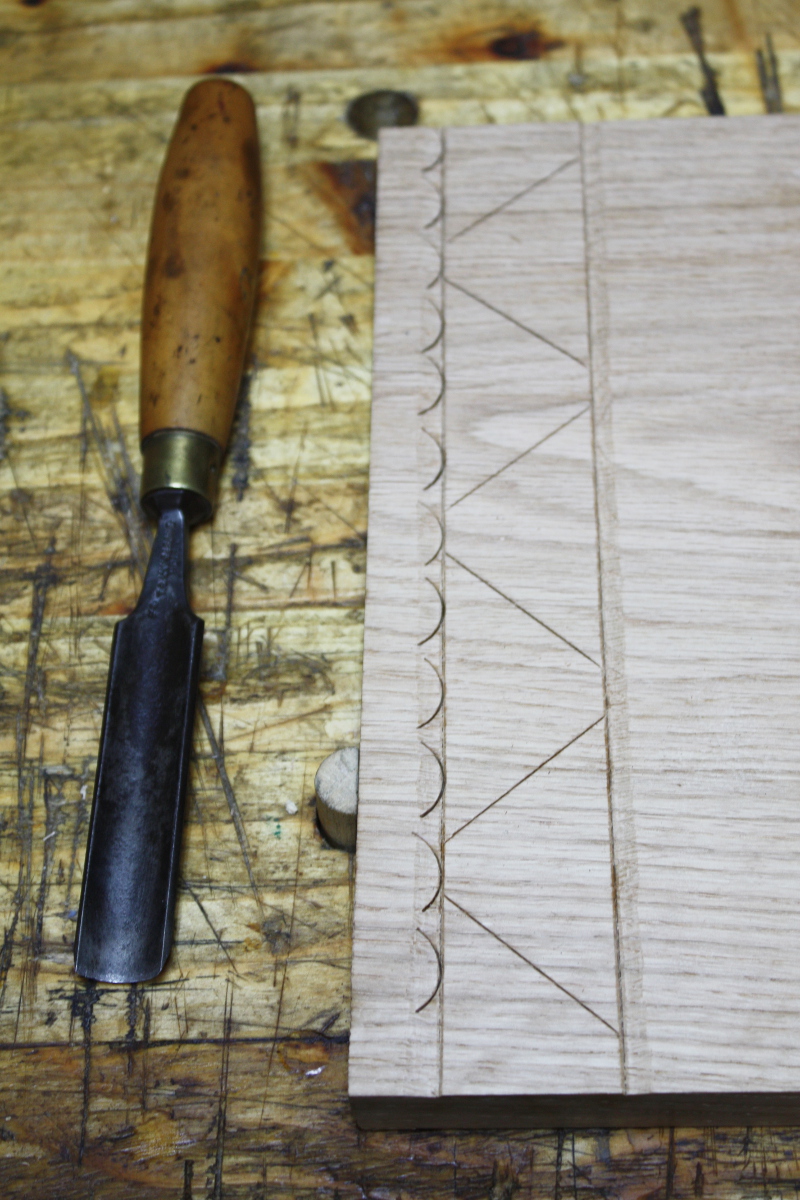

Just a little decoration on the top.

Some straight-chisel work, and then I want to treat the long lines like a knife wall, so there’ll be a little low relief to it.

That’ll do. Next, gouges…

A bit of experimentation and picked out two.

Right, so chopping with the larger chisel to set up the pattern:

And now use the smaller gouge to take out some scallops so the endgrain edge has some decoration.

Okay, now some punchwork to add a few decorative points.

I’m happy with that.

Okay, now just some breaking of edges and shaping of the front edge:

Gooseneck scrapers are great for this.

Okay, that’s the lid done.

Add some linseed oil and that’ll fit in nicely.

Now the base. I don’t have enough ash offcuts to make a shiplap base, annoyingly, but I have a small offcut of an ash board that I can use if I hack it in half and make it into a panel.

Flattened it with a #05, but I’m not thicknessing this by hand.

I hate the noise, the PPE, the mess and the fuss, but the speed is nice.

Done in about 15 minutes. That would have been a few days before now.

Okay, so #05 to clean the edges, then do an edge joint with the #05 and #08 and glue up with liquid hide glue.

That’ll be ready come tomorrow and I’ll just attach the board to the base and fit the hinges, douse it in a few coats of BLO and that’ll be that.