Hm. Well, I guess not every day is going to be a great shed day. Stupid “job” and stupid “mortgage payments”…

At least the walnut blank for the bandsaw box came out allright. (That white glue streak is from where the bad saw cut was. The design will have to cut around that).

(That white glue streak is from where the bad saw cut was. The design will have to cut around that).

But I couldn’t drill the tabletop for the threaded inserts because they’re not here yet, so I just cleaned up the glue squeezeout from the table legs.

The new plastic razor blades were actually really useful here.

I guess you could just have a thin plastic knife for this (or a scraper if you didn’t mind then scraping out any scratches from the surface finish). But they were on sale and try anything once.

I got out the feeler gauge as well. There were places here and there where I could get a 0.2mm gauge in, but only on one shoulder was that consistent. And the ends didn’t look too bad.

Mind you, the bolts that are to hold the tabletop on… they were 70mm. They really should have been 75mm (but I couldn’t find those. Time to go hunt round the pick-n-mix hardware section in Lenehans and Woodies I suppose).

I mean… they’re nice and all but… I don’t think 5mm of thread is going to have much strength, y’know?

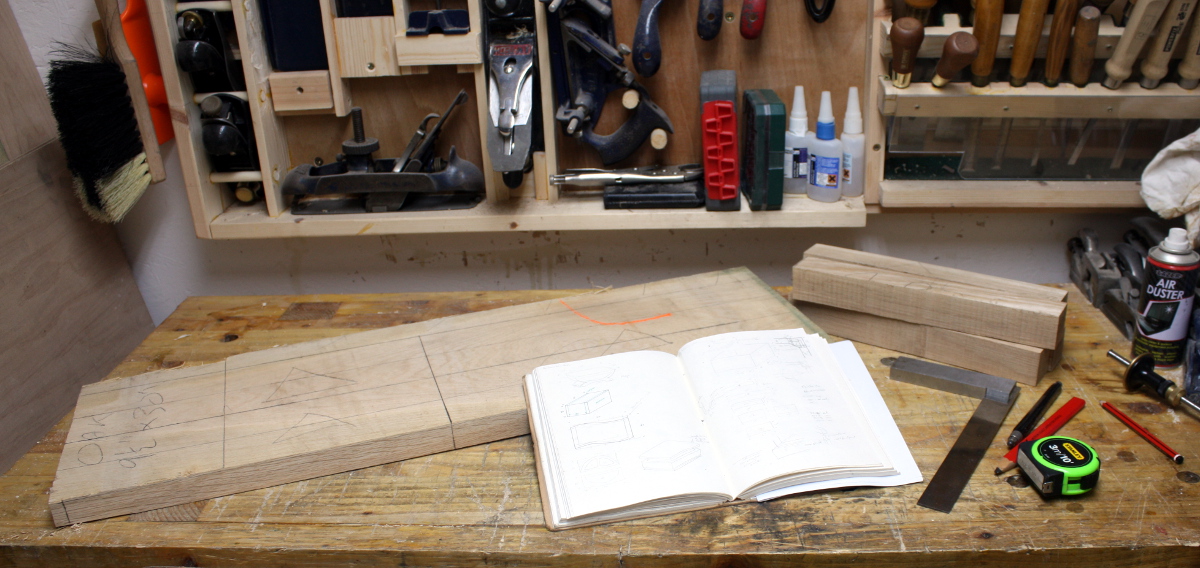

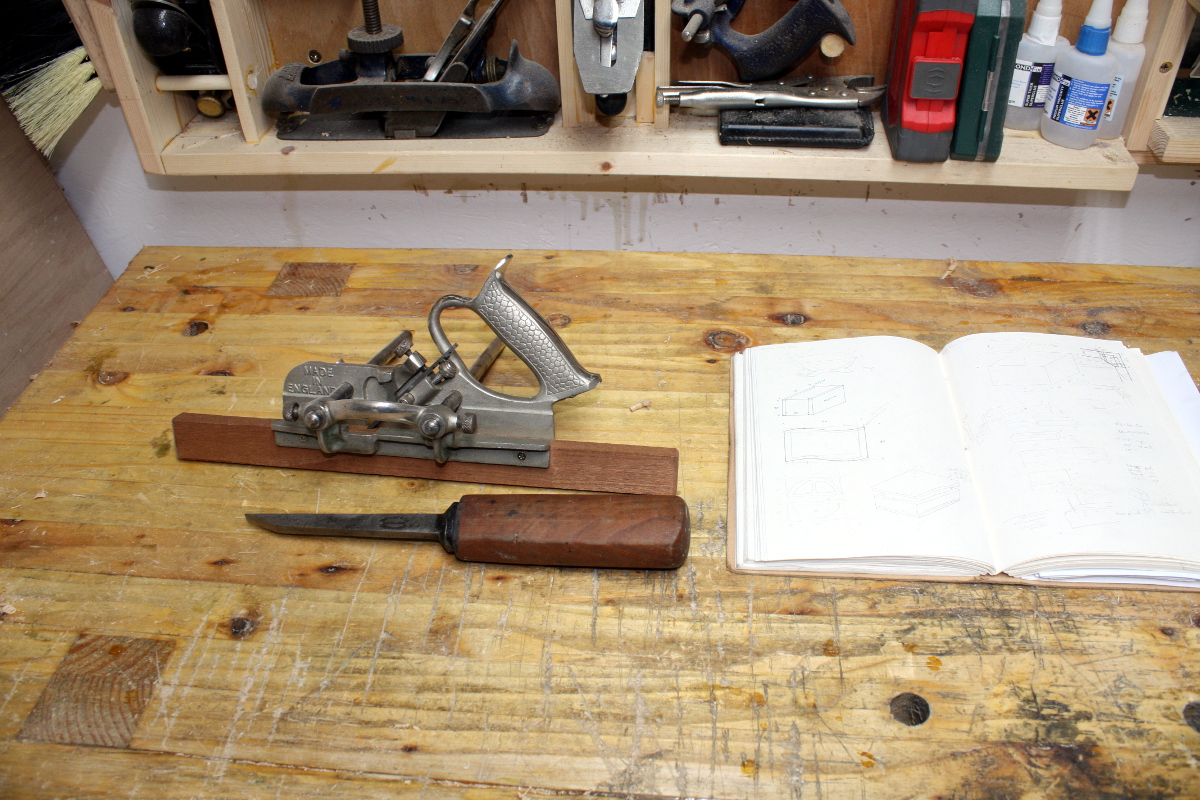

So, suitably annoyed I turned to the new project. Now it was 2100h by this point, so anything noisy was right out, but there was still some marking up to do. And I had to hunt up some timber for panels.

This should do it, but there’s a catch… that has to get resawn.

I’ll rip it down the centerline (well, not the centerline but the center line of the grain pattern, for symmetry) and trim off the edge waste with the bandsaw, but the resawing has to be done by hand because the panels are too wide (they’ll be 4 and five-eighths wide and who invented this stupid system of measurement and I’ll be converting this to mm as soon as I finish converting the rules-of-thumb on panel sizes and groove depths).

I remember the resawing from the cot. I’m not looking forward to this. I’m just hoping that it’s easier to resaw a 4 and 5/8″ board than an 8″ one. And maybe I’ve gotten better at this in the last year. Maybe.

So the posts are cut long to leave horns (yes, that’s the term) above and below the mortices (and leave space for legs as well). Once the mortices are chopped and the tenons fitted those horns can get trimmed off but during the mortice chopping they give some extra strength to the piece. I forgot this when making the front legs in the sidecar cot and chopping those out was a bit of a faff as a result to avoid accidentally splitting them out.

So the posts are cut long to leave horns (yes, that’s the term) above and below the mortices (and leave space for legs as well). Once the mortices are chopped and the tenons fitted those horns can get trimmed off but during the mortice chopping they give some extra strength to the piece. I forgot this when making the front legs in the sidecar cot and chopping those out was a bit of a faff as a result to avoid accidentally splitting them out.

Then looking at the rails and stiles. The rails are straight enough, so I have face and edges nominated, and I marked them off for a 3/4″ thickness.

The stiles on the other hand, all have a kink that I’ll have to cut out.

Lovely rays though.

I’ll just mark off the straight portion and roughcut that on the bandsaw and then plane the faces (I’ll do something similar on the rails – roughcut outside the line and plane the faces – I’d like to save a chunk of the waste though, quarter-inch stock is handy for boxes).

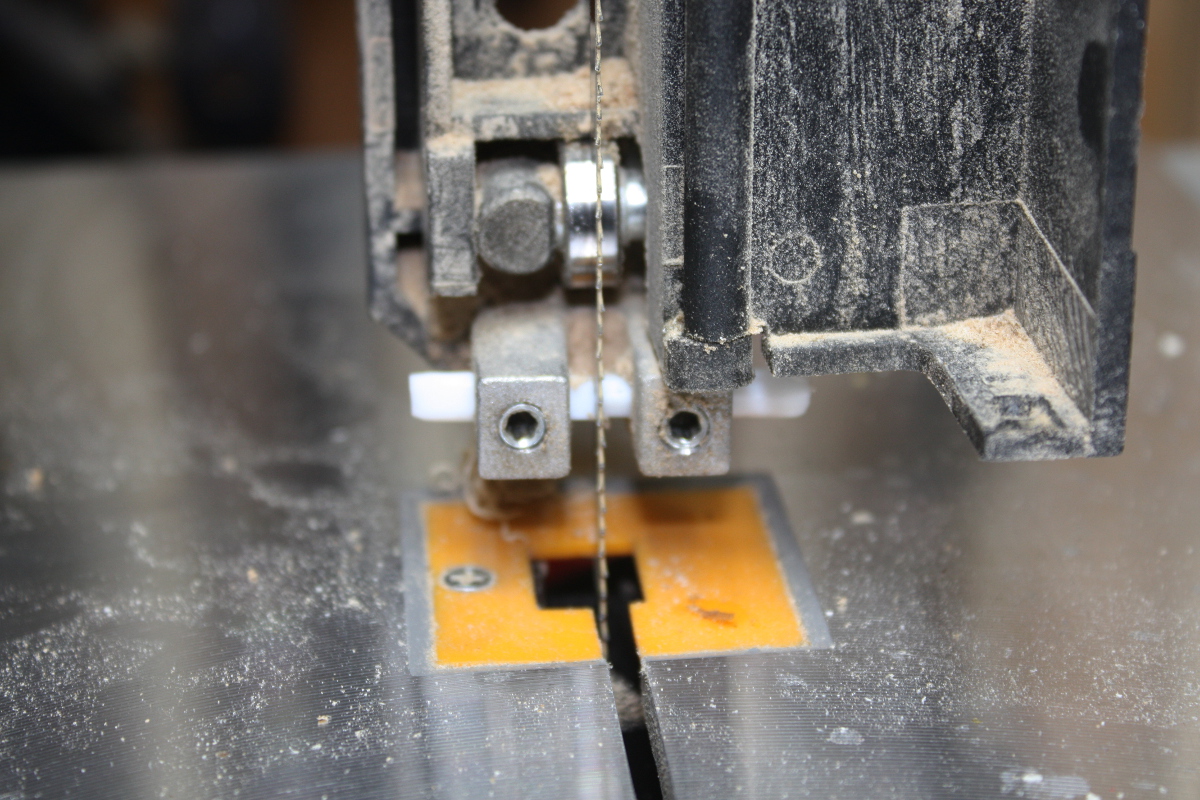

Prepped for tomorrow. I’ll run a scrap through it to see if those guides are behaving themselves first, but I may need to swap them out and maybe the blade as well.

…downhill on a wet slope towards a brick wall while blindfolded.

…downhill on a wet slope towards a brick wall while blindfolded.

Some brass-plated hinges for the next project, a silicone hose adapter to try to improve dust extraction from the bandsaw:

Some brass-plated hinges for the next project, a silicone hose adapter to try to improve dust extraction from the bandsaw: