Last project finished, next one not properly started yet (just have the rough cuts done) and another in mind but not off the notepad yet. So now’s the time to work on the shed itself…

That’s the dust collection for the shed (it’s collapsed because the vacuum hose got clogged with shavings and the shop vac managed to pull enough air out of the barrel for atmospheric pressure to crush it). It’s a bit… big. For the shed at least. So a while back, I got a smaller drum.

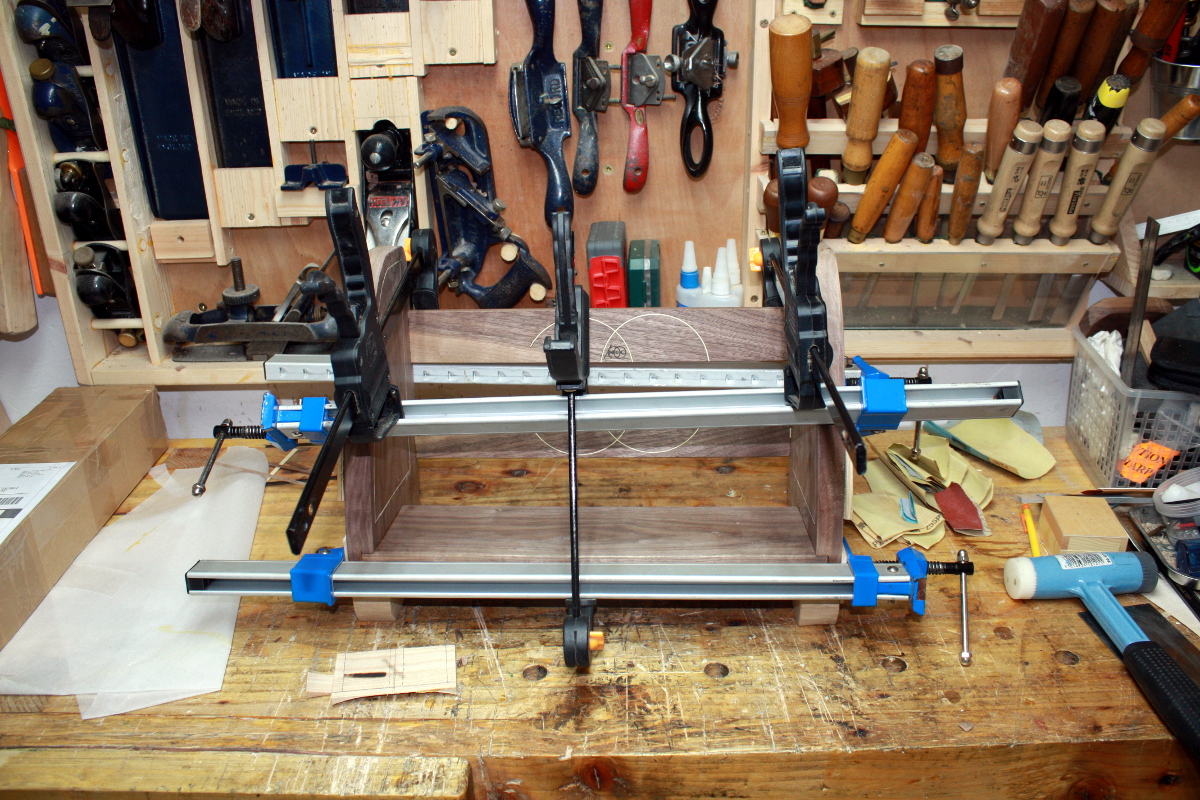

And it’s been sitting there since I bought it, getting in the way, because I was trying to get other stuff done. So…

Out with the old…

Out with the old…

And mark out and measure for the minicyclone seperator in the lid of the new drum, cut out the large hole with, of all things, the lie-nielsen radius cutter I was using for stringing on the last project, and then drill the holes for the attachment screw and fit it. In the end I didn’t use the sealer though, I’m not sure if it’s needed just yet.

It’s a wee bit smaller 😀

May need to re-jig how it’s held upright because unlike the older drum, this one has no side handles to thread with bungees.

Much smaller and neater. I didn’t use the sealer yet – I was mucking about with a safety valve to stop it getting crushed like its predecessor, but discovered that even with the 10mm hole in the lid wide open I was still getting suction on the main hose, and if I blocked that main hose, the 10mm hole wasn’t enough to stop the vacuum trying to collapse the drum. May need to rethink that a bit – it could just be that the smaller size results in far more rigidity and I don’t need it. Or I may need it later due to wear and tear. We’ll see.

Either way, more room!

And more clamps! There were a few 3″ clamps going for a fiver per pair on ebay so I grabbed them. They’re getting some PTFE lubricant here. At some point I really ought to take off the old paint and repaint all of these but I like the old record blue and I’m not sure I want to go into learning how to stove enamel stuff in the same oven we cook dinner in…

(Oh and the calculator is because I can’t multiply by 1.618 in my head)

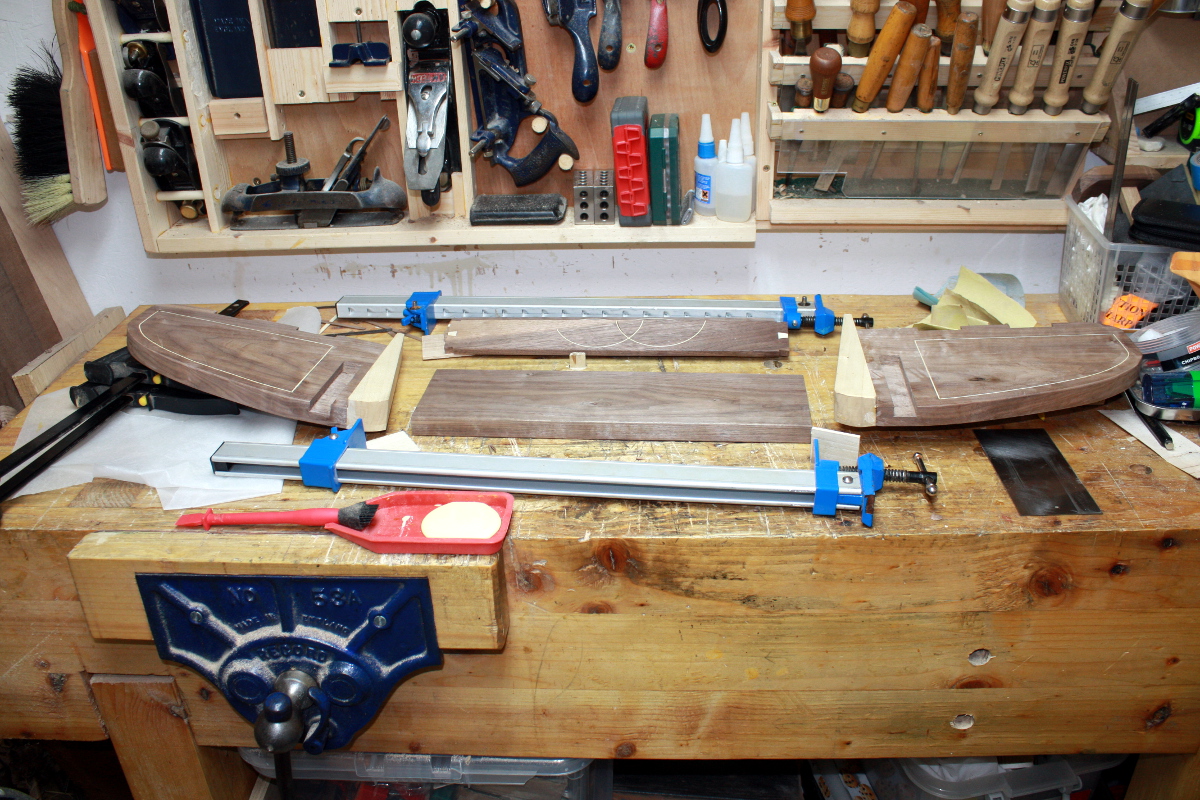

And this is the next project after the next one; it’s not off the notepad yet but I was looking at how beech and walnut look beside the rippled sycamore that I want to use in it, trying to figure out colour contrasts so things look matched rather than looking garish, but also letting me keep mucking about with stringing.

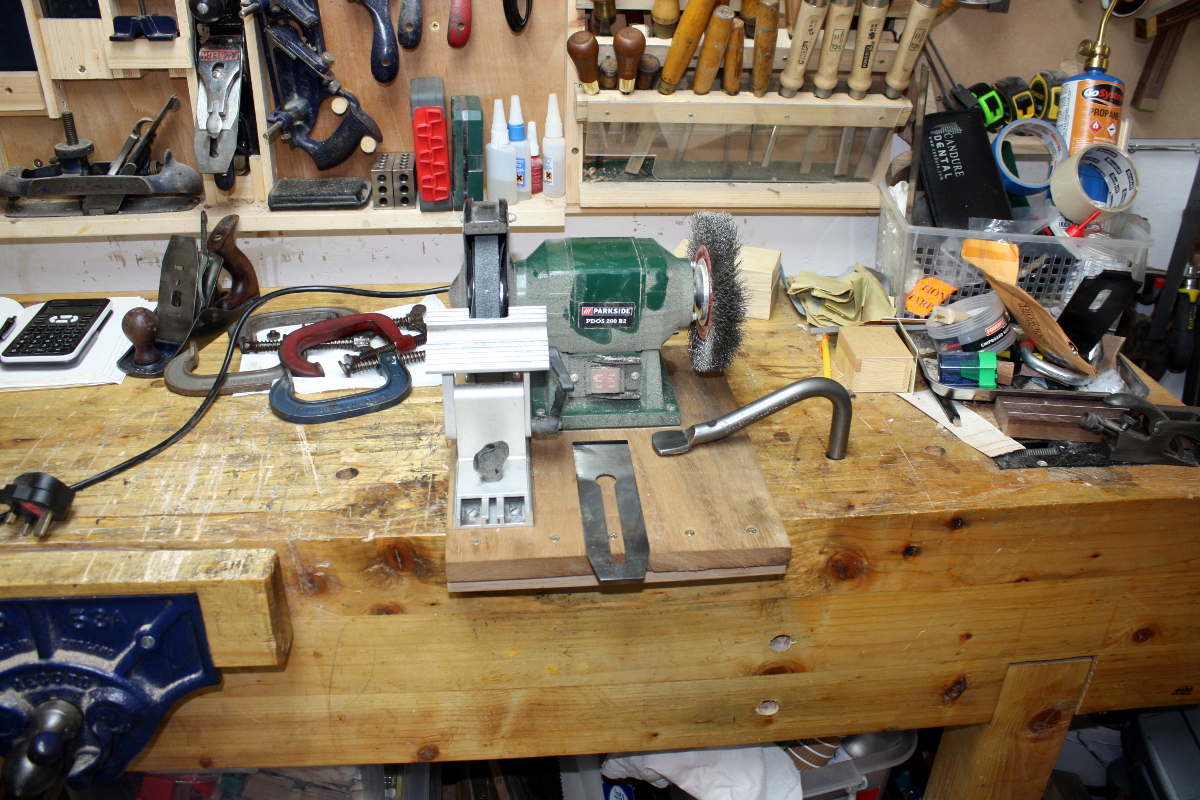

I do have one shed task left though, and that’s to grind a camber in the new scrub plane blade. It won’t be anywhere near as severe as Sid’s camber, that was something like a 4″ camber, this will be about 7″ or so. I’ll get to that next, and then I’ll get back to the locker.