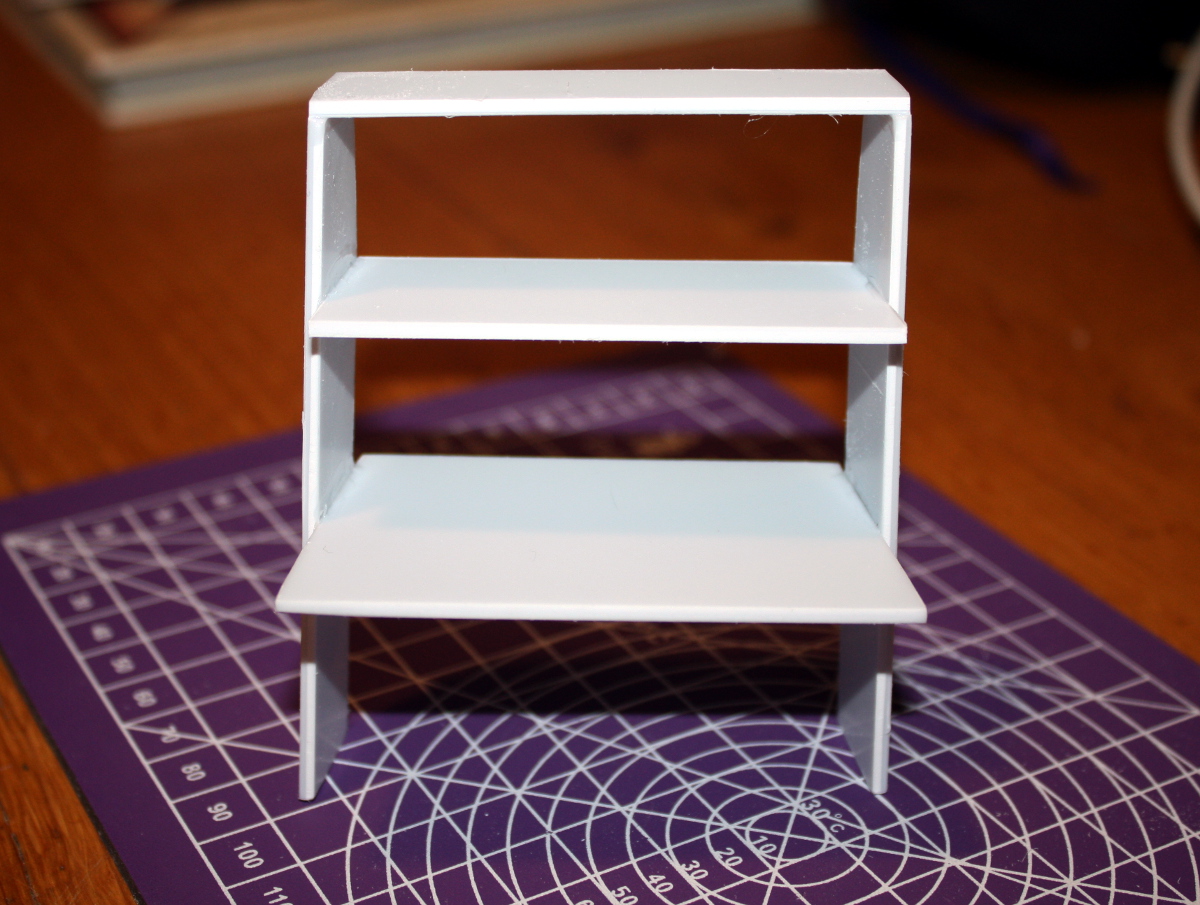

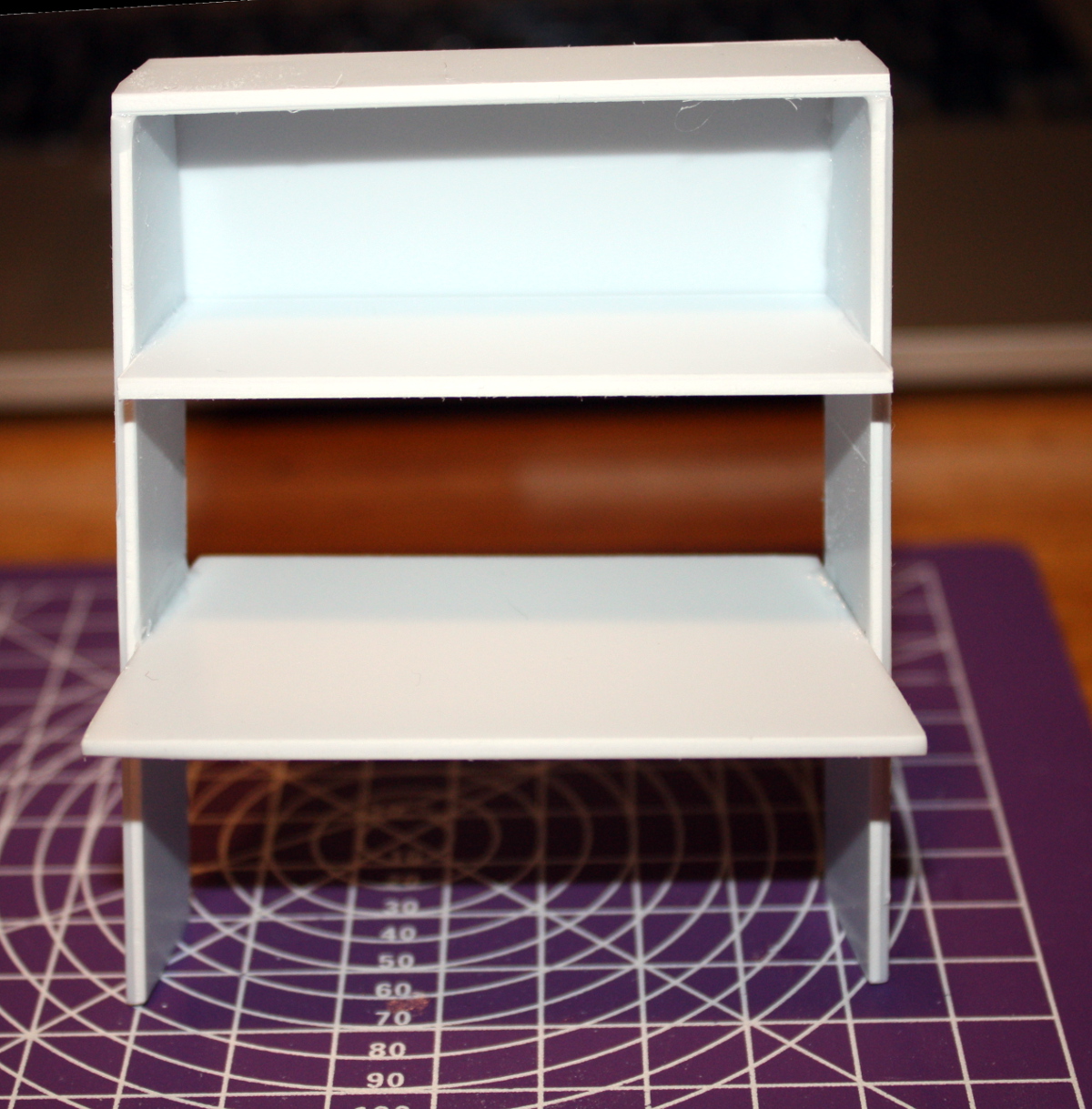

So I was really just at a low energy setting this weekend, and it was one of the first rains of the coming winter and even just looking at the shed was making me tired, but I have been wondering about something with the design of Calum’s shelves/desk thingy, which is whether or not to put a backing board behind/between the top two shelves. It’d stop stuff falling off the back of those shelves, give a larger contact area with the wall, and stiffen up the whole carcass; but it’d change the look of the unit quite a bit and the joinery might get complex unless I cheated and used a router to carve out a rabbit for the panel.

So, what do you do when you’re too tired to go to the shed and still want to see what it looks like? Well, there’s this stuff called styrene (or plasticard or ABS or any one of a dozen other names). You know it, it’s what airfix model kits are made from, and sheets of the stuff are where you start for scratch-built models. And I had a few sheets because Paul Sellers had pointed out a while ago that it was handy for templating curves and I was planning to use it for some boxes. Then this weekend I was watching an Adam Savage one-day build doing some scratch-built modelling for fun, and thought Calum might find that fun to do (because he’s kindof young for the complex airfix kits, but he’s more than ready for scratch-built stuff) and went off and got some solvent cement and we had some fun (modelling, not sniffing solvents). I mean, he’s more looking forward to painting it, so I’m off to the modelling shop for some thinner and paints for the airbrush tomorrow, but he got a kick out of seeing it built.

BTW, ignore what Savage builds there, it’ll only depress you if you try it, remember he worked professionally doing modelling for years for Industrial Light and Magic, so he might act the eejit all the time, but the man knows his modelling, and so do you if you ever watched Star Wars in the last 20 years or any one of a few dozen movies.

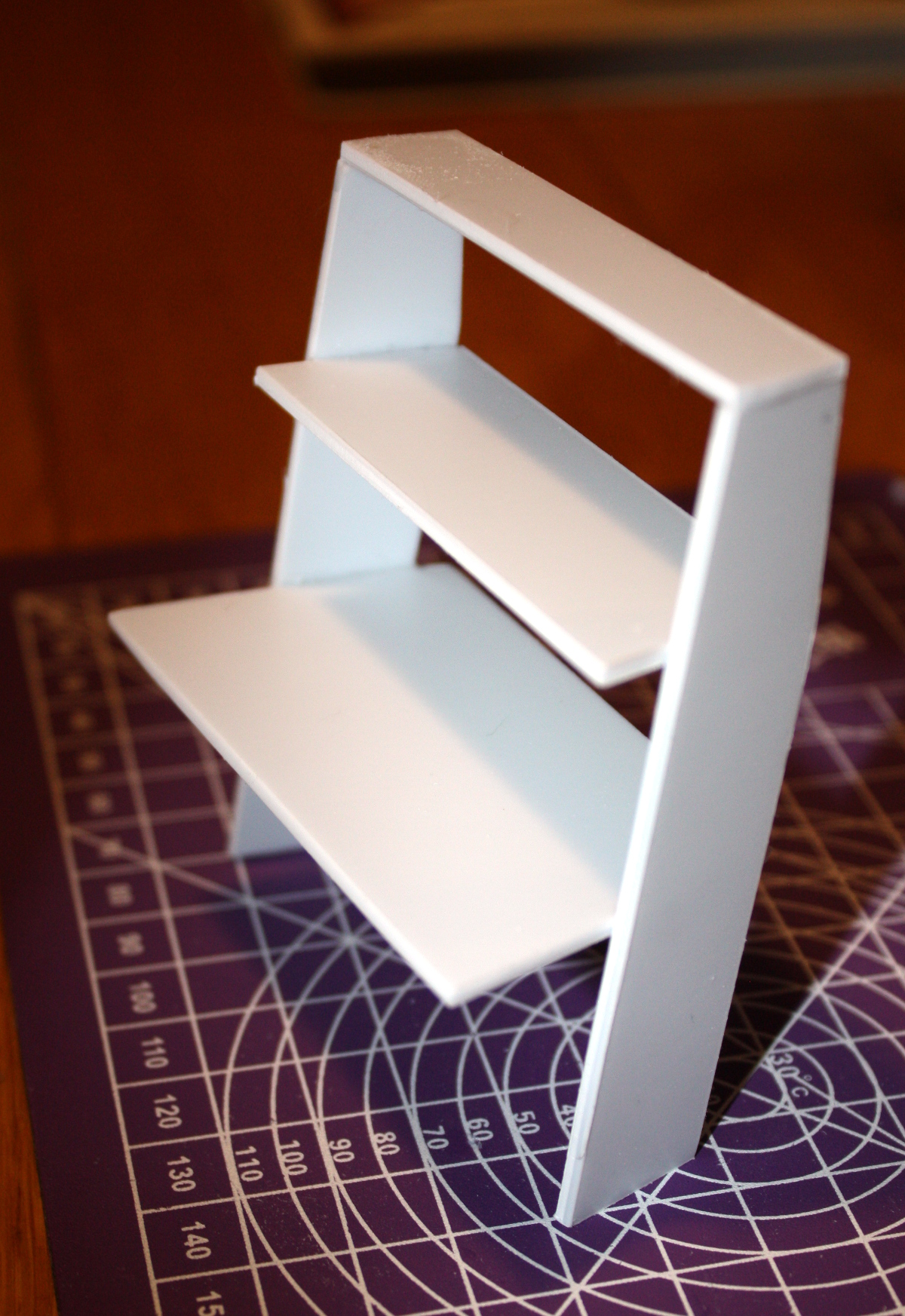

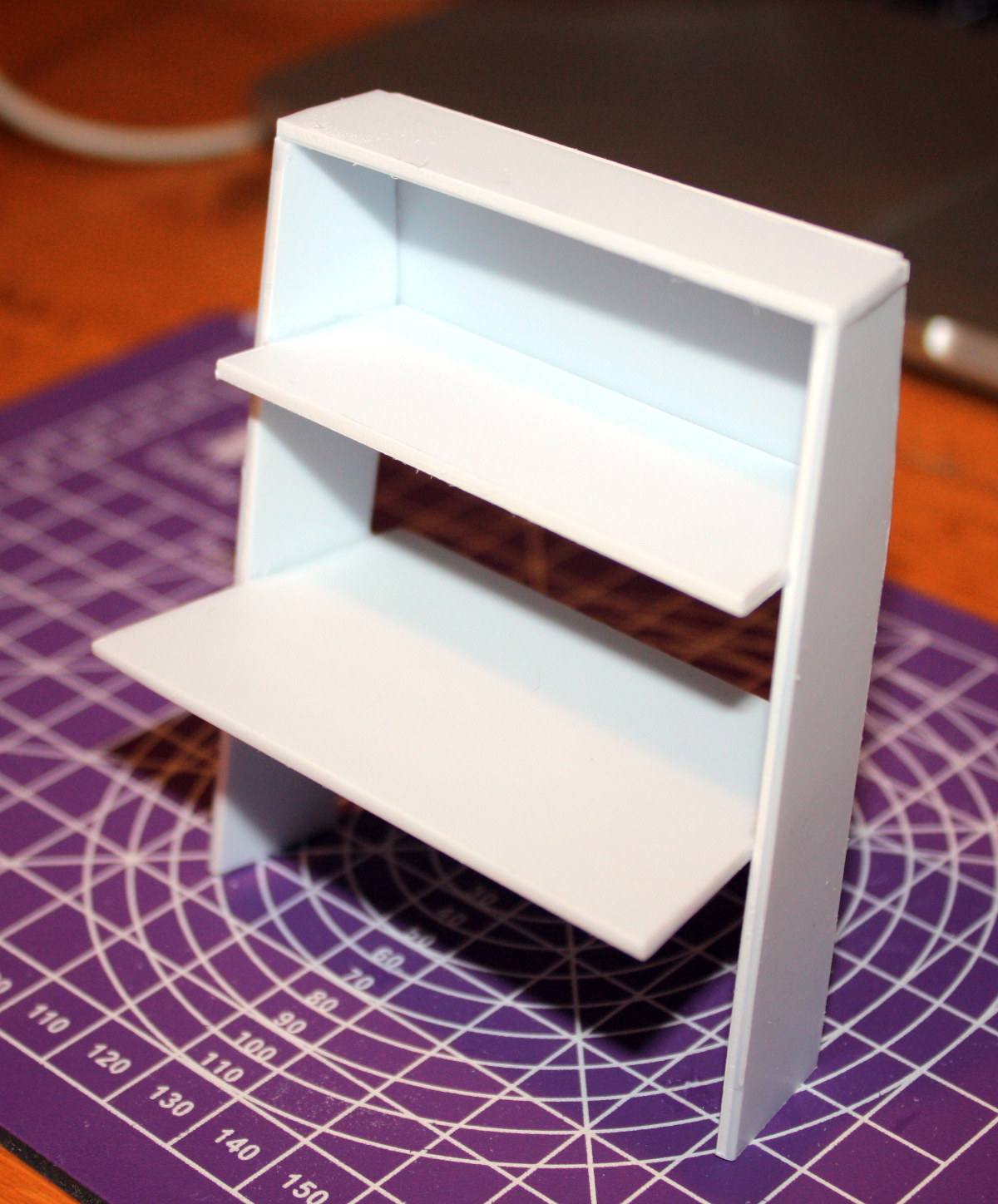

So anyway, after we’d built a little boat-spaceship-box-thing for Calum, and it was after his bedtime, I did a bit more cutting with the 2mm thick styrene sheet I had, at a 1inch to 2mm scale, and built his desk/shelves unit:

It’s nice to be able to see it from all around. It’s like CAD for old people.

And then I could quickly add on the backing board I was wondering about and compare them:

I mean, messy as all get-out, if I was serious about modelling it there’d be a lot more sanding and some painting (hell, might do that just for fun with Calum later), but it’s not terrible for 15 minutes of work at the kitchen table with a ruler, scalpel, emery board and solvent cement.

I must remember to do this next time I build something and don’t have a full picture of it in my head (or even if I do, it’d be an interesting thing to see how close the model matches the final product).