We had to run off to a graduation on Friday, but when we got back I spent a rather rushed half-hour in the shed. Thing about that sort of thing is that it gets… messy…

So first things first on Saturday, clean up a bit…

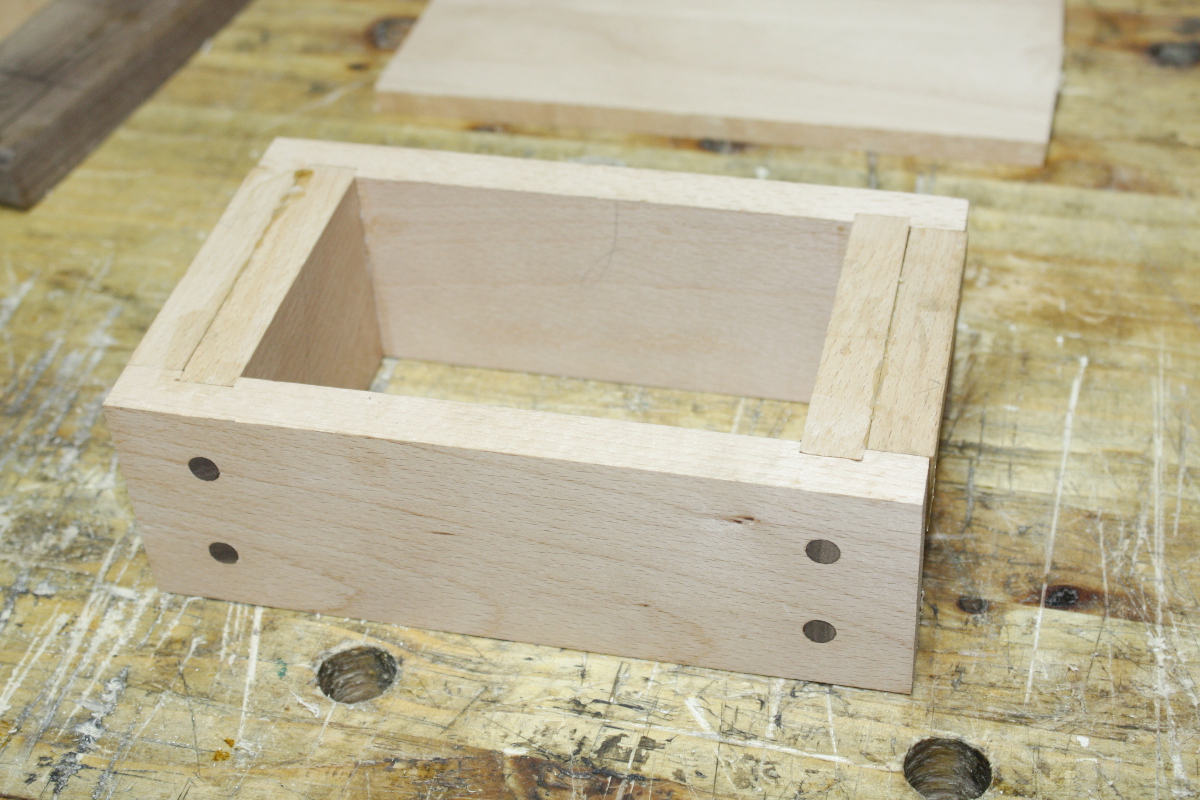

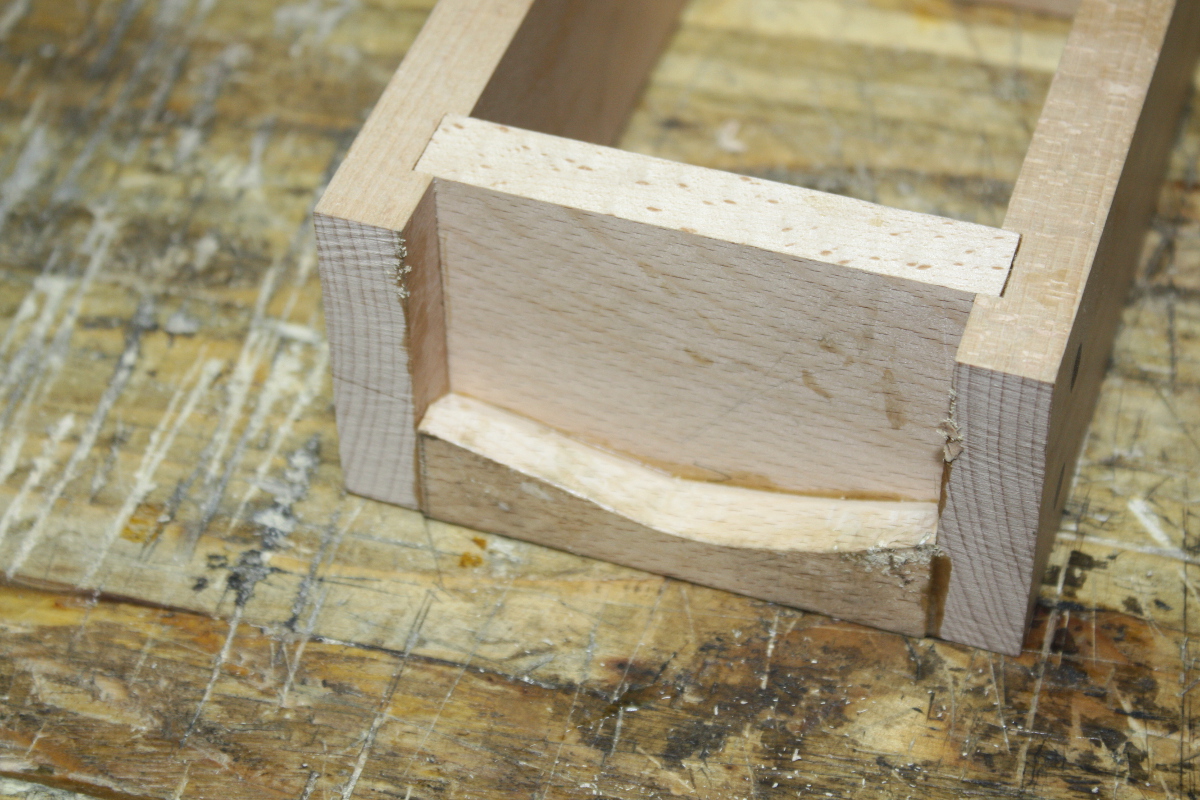

Right. Next, trim up the other end cap, and set the locking wedge position and glue it in place…

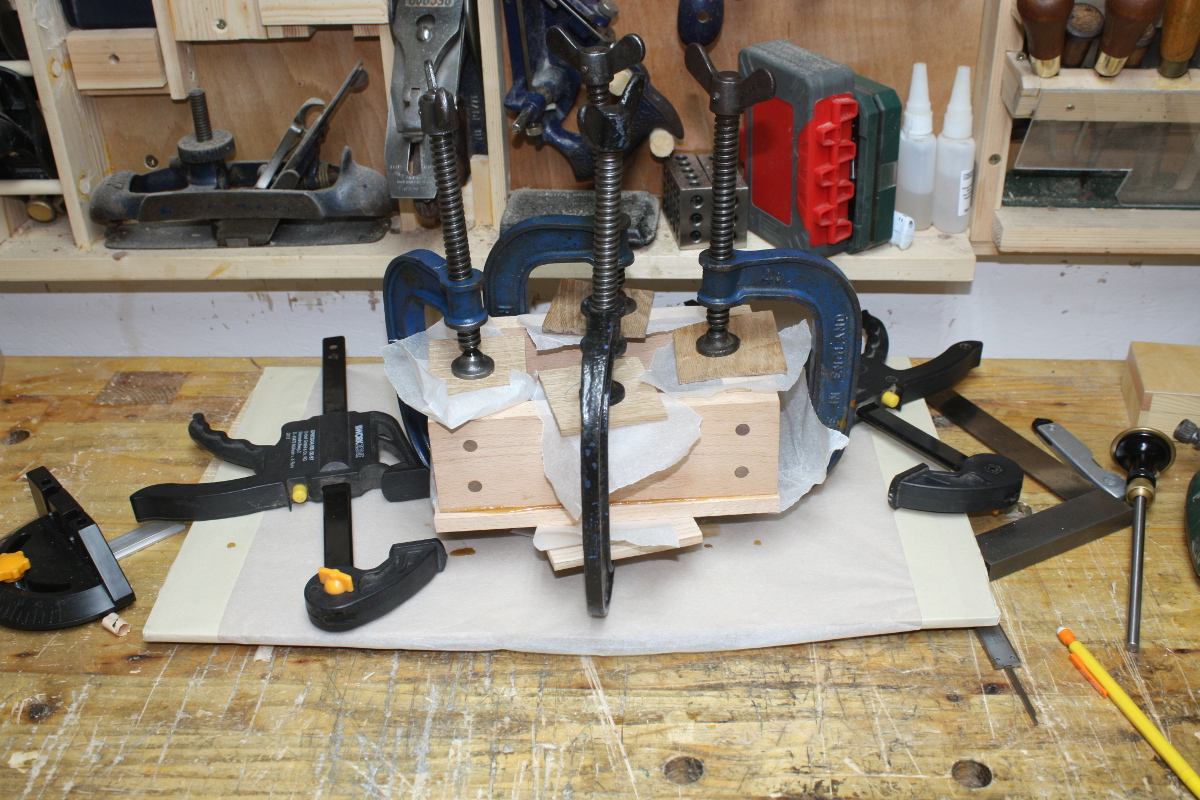

And yes, that is the finish starting to go on the box and the key; and I have jumped the gun there a bit and I pay for it later. The finish by the way, is half danish oil and half turps, mixed in the cup (the office has a snacks thing they do where you can get free peanuts and we use those little paper cups to serve them in; I just hang on to mine and they come in useful in the shed later).

I don’t use Rustins for any particular reason; it just happens to be the brand I could find in the shop. I don’t use danish oil all that much really, but the consensus was that it works well for beech when I asked around. And I have to admit, it works quite well, though it’s a strong-smelling finish for the first day or two.

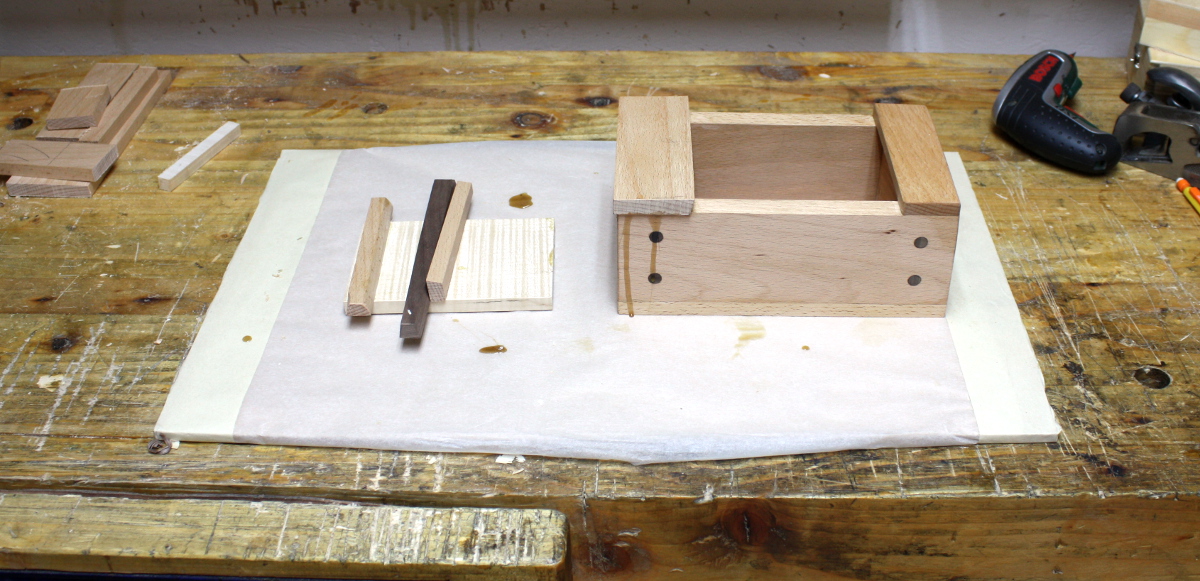

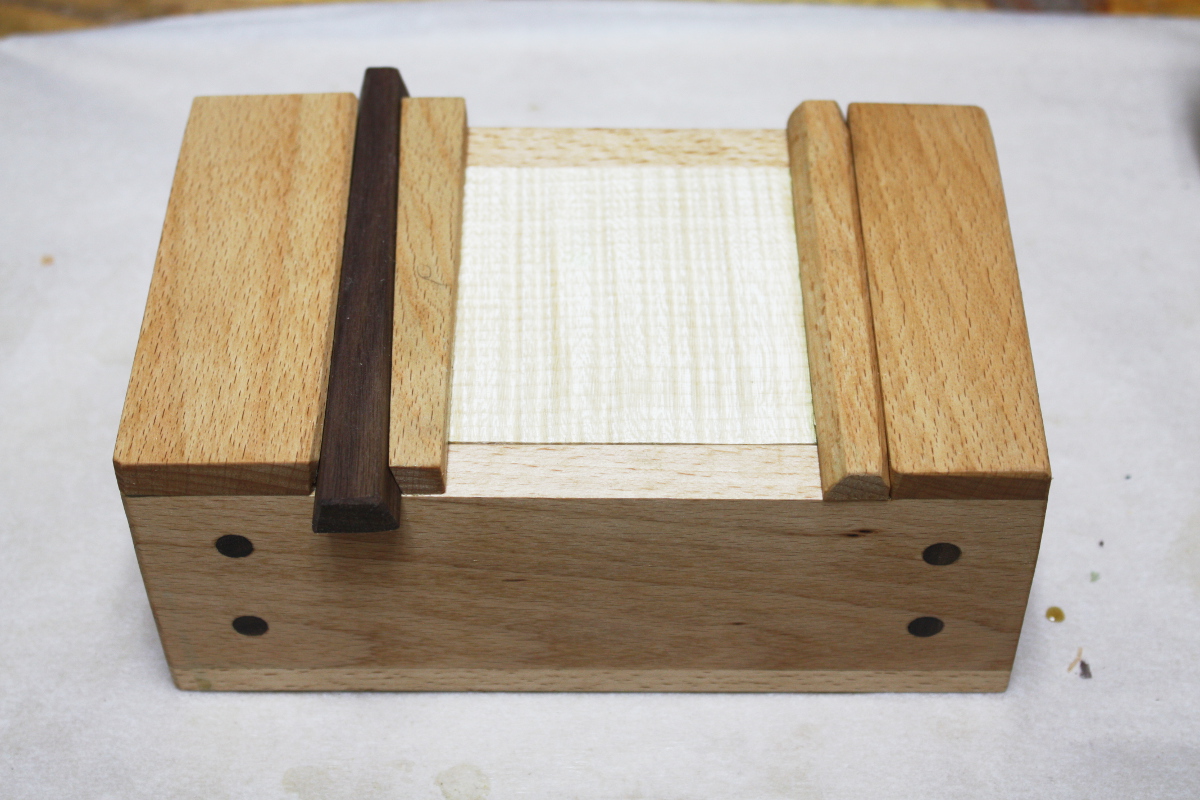

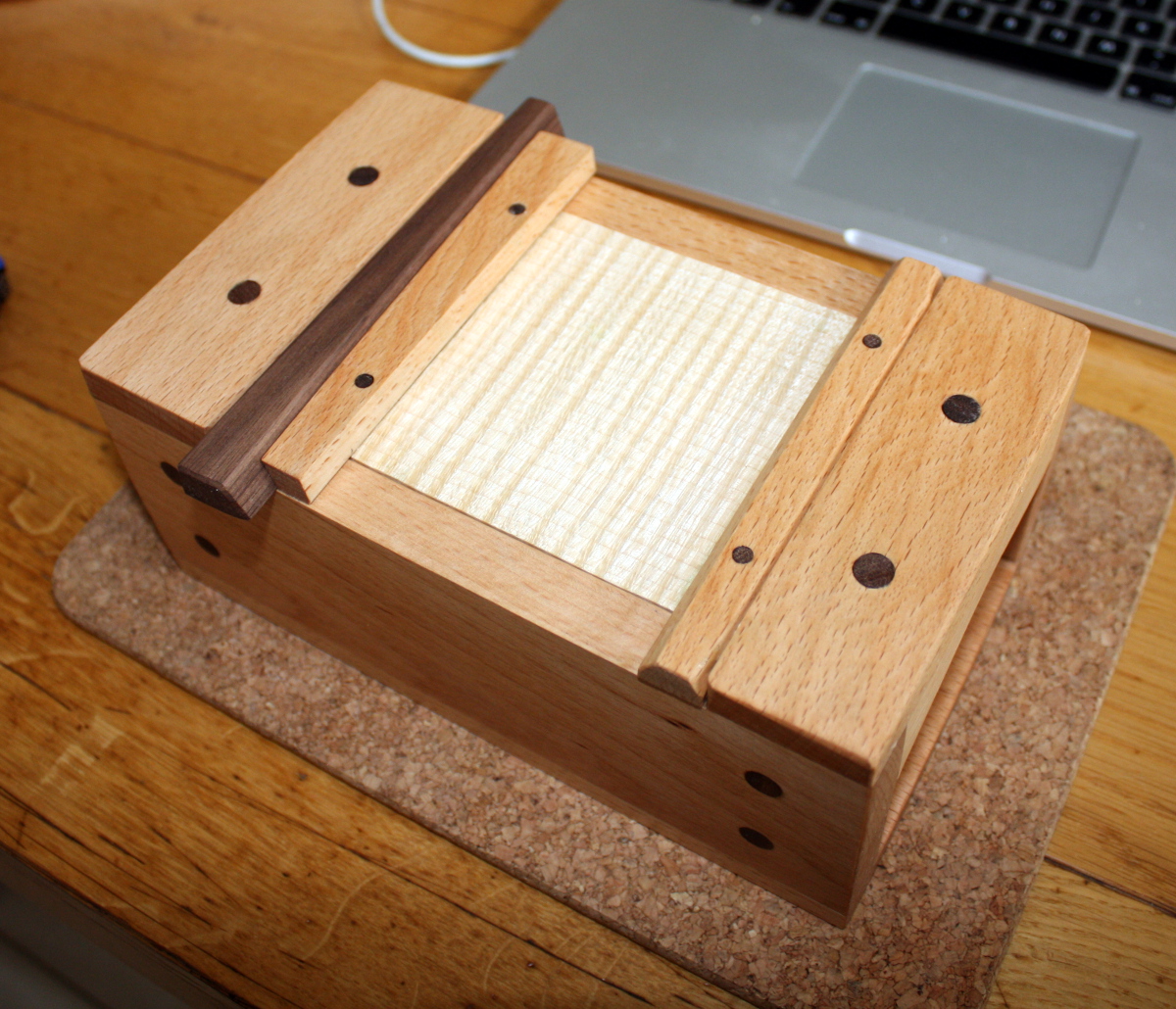

All glued up and finished with the first coat of oil&turps…

And then after it had had a few hours to dry, a test fitting…

BTW, that’s the third walnut key I made. The first one I cut looked fine but by the time I’d pushed it in far enough to lock the lid, it was half-way out already. I re-cut it and somehow mixed dimensions up and had to redo the redo…

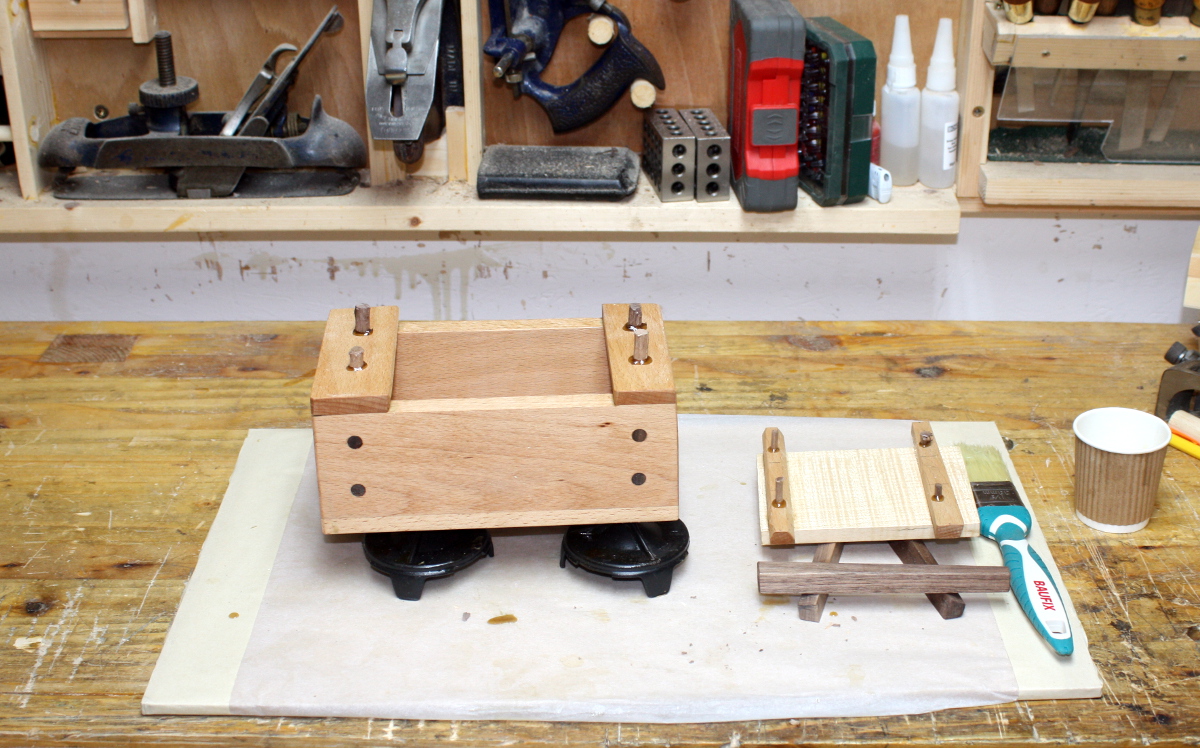

It was at this point that I realised I’d forgotten a step…

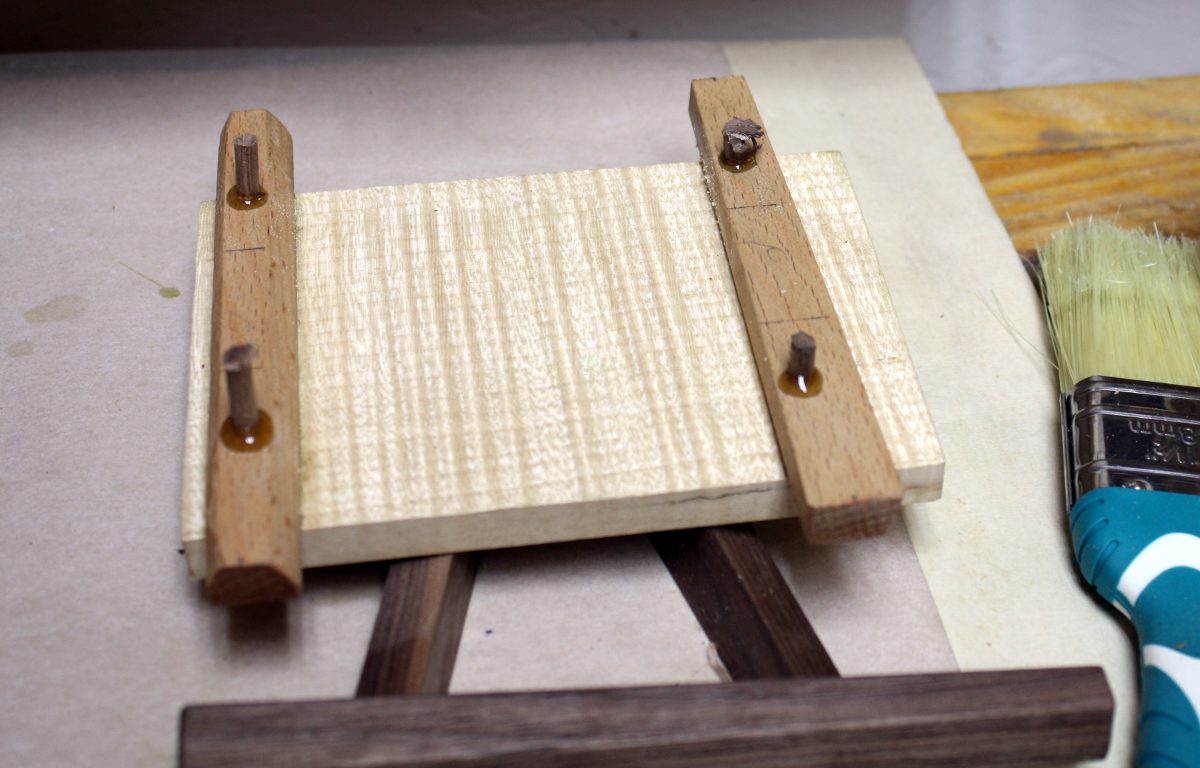

No pegs in the top. I mean, the glue would probably hold but the forces on the top pieces are all shearing forces acting across the lid so the only thing holding the pieces in place if you really shoved on the wedge would be the glue, and along what is probably its weakest axis. And I get paranoid about such things so…

Yeah, I know, drilled right through the finish too. Oh well. Now the end caps are fine, the five-sixteenths size pegs there don’t come close to blowing out the five-eighths material, but the stops on the lid themselves are far thinner, so I needed a smaller peg, somewhere around an eighth of an inch or just over. And my dowel plate only goes down as far as 1/4 inch and worse yet, with small pegs like that, matching the peg to the hole gets more critical and all my drill bits are metric (the auger bits are all imperial but don’t drop down that far). I was going to use the Bosch drill for the lid because for small thin stock and small holes, you really do want some speed with the lidl-standard drillbits I have; which means the eggbeaters can’t really cut clean holes in small stock. Which means the pegs have to be metric for two reasons.

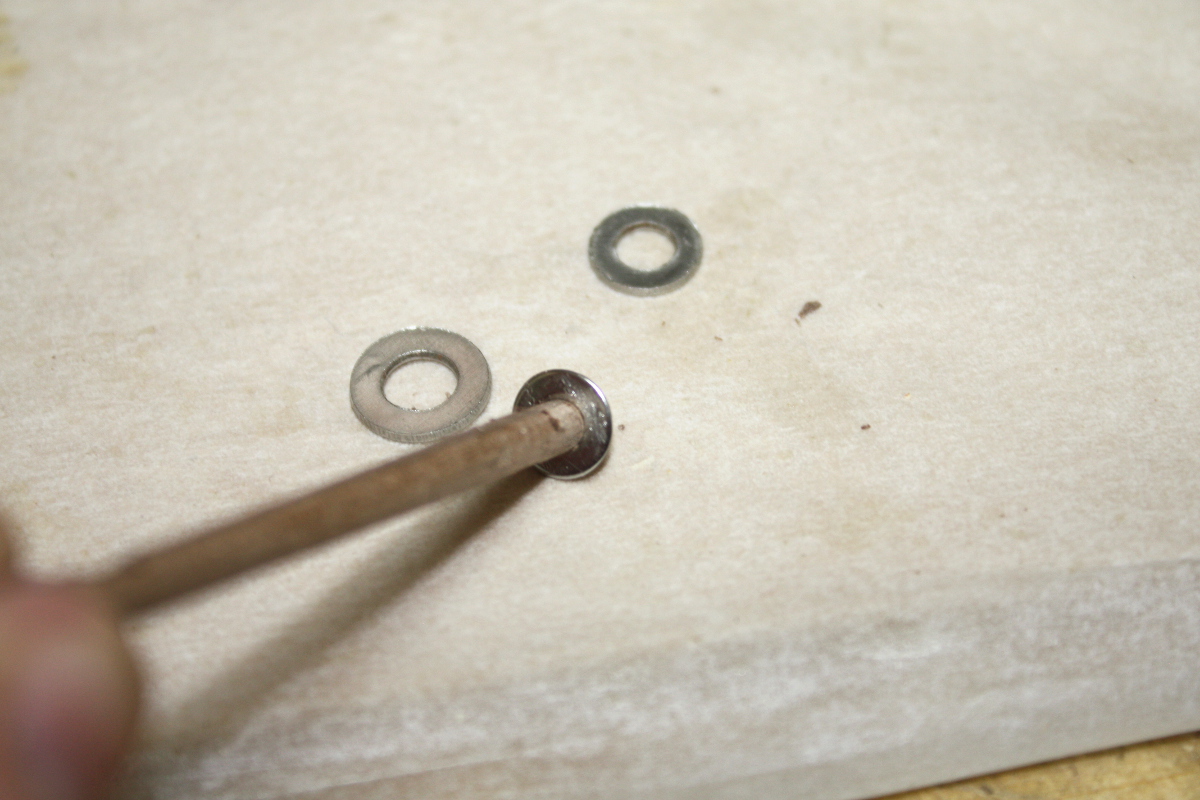

So… steal another Paul Sellers idea. Knock a few pegs down to 1/4 inch size, then whittle an end to a point and use washers as little metric dowel plates…

Tappy-tap-tap…

Also, the Record Imp earns its pay again! I had no other way to hold those washers well. Trying to use the dowel plate would have been awkward at best. Now just work down through the sizes, running through the washers a few times to get a reasonable surface finish before dropping down a size.

End result; not too bad. Mind you I broke three getting those two made – belting something that size through a too-small opening with a lump hammer is kindof a delicate task. If your alignment is off, the peg shatters.

Worked though.

Now, wipe off the excess glue with a damp rag and wait for an hour for it to set up enough and then…

Flush-cut saw, chisel, and then a pass with the #04 to get a smooth surface on both sides of the lid and on the end caps. The lid is a tad more delicate, but…

Not too bad. And repainted that first coat of finish over the reworked parts.

I rather think that the danish oil works well on that rippled sycamore. It dulls the whiteness, but the figure really does pop.

And some CA glue and felt to line the base and that’s it all complete. Just left it overnight for the finish to dry a bit more, then on Sunday morning while herself is off at a fun-run (don’t ask, I don’t know why those two words are beside one another, it makes no sense to me either), brought it into the house, buffed it up and gave it a light coat of beeswax paste (that’s beeswax mixed with turps) and buffed that as well.

And because you can’t give a box without some contents…

Happy Fathers Day Dad!