So one of the tools we used in the woodturning class before lockdown, was a wide parting tool – about a centimeter or so wide. I don’t have one. And I figured, it’s just a HSS blank ground to shape and fitted to a handle. Machinists make their own lathe tooling as a basic skill, and woodturners as well for some tools (not seen any make their own bowl gouges yet though). So. To ebay, and yes, you can order metal through the post it turns out. One 12x12x200mm lathe tool blank in HSS isn’t even very expensive (though I couldn’t find anything longer than 200mm in HSS, it seems that’s the upper limit for off-the-shelf square bar sections unless you’re ordering metres and metres of the stuff).

The metal detectors says that there’s only 2-3 inches of tang in the parting tool I do have, so that much in the handle gives that length of tool, which is more than enough in a small shed.

Out with the Imp and the angle grinder and the ridiculously small set of metalworking tools I have, and a bit of beech to laminate for a handle.

Not the cleanest cut in the world. But I never said I was any good at metalworking 😀 I can fine-tune the actual tip over successive sharpenings on the grinder. One more cut on the back side of that bevel, then spindle turning a handle from laminated beech and using a pipe fitting as a ferrule and grinding the tang section of the blank to round for the handle and then lots of epoxy and….

One beading and parting tool.

I’ve used it a fair bit in the last few days. It’s not bad at all, the handle is definitely more comfortable than the others I have, and the tool itself is rock-solid in the hand. The tip isn’t quite right yet though. The bevels need to make a sharper angle, somewhere down between 40 and 30 degrees at the tip. But that’s something I can do over successive sharpenings and sneak up on it.

I’m quite pleased with that now.

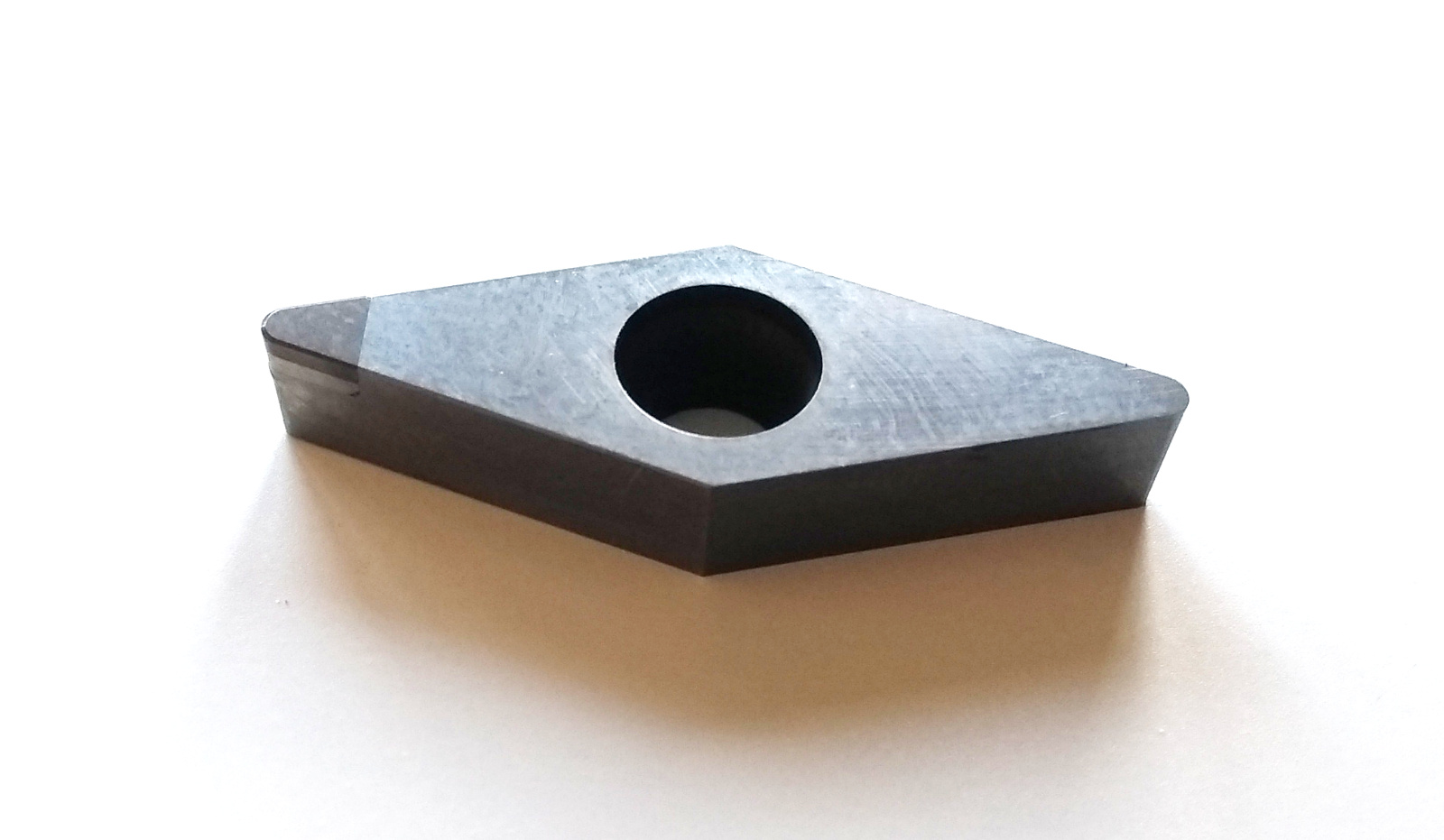

So I also ordered a few 300mm lengths of bright mild steel (cold rolled if you’re speaking American) and I have a bit more beech and ash for handles and I’ll make some more, but this time I’ll use some of these…

There are actually a few carbide inserts on the way for this, but that’s not one of them – that’s a CBN insert, you can see it there on the tip on the left hand side. I’m not sure if it’ll work any better, but I was curious 😀 Give me a few days and I’ll know for sure.

And there are some more, if much thinner, HSS bars also in the post for things like point tools and beading tools and the like. It’s rather satisfying, is toolmaking…

Tags: carbide, hss, toolmaking

Mark,

Interesting. I liked the use of a metal detector to figure out how much tang you had.

ken

Thank an old episode of ER for that one Ken! 😀