So, one of our team at work went on holiday to Peru and left his mug behind him in Dublin. And was scheduled to return on April 1.

So what happens next is entirely his fault.

(COL-PROD was a work project thing which won’t mean a thing outside of work)

You know, it’s harder than you think to shatter a mug using a wedge from the inside out so it doesn’t look like some heathen just belted it with a hammer…

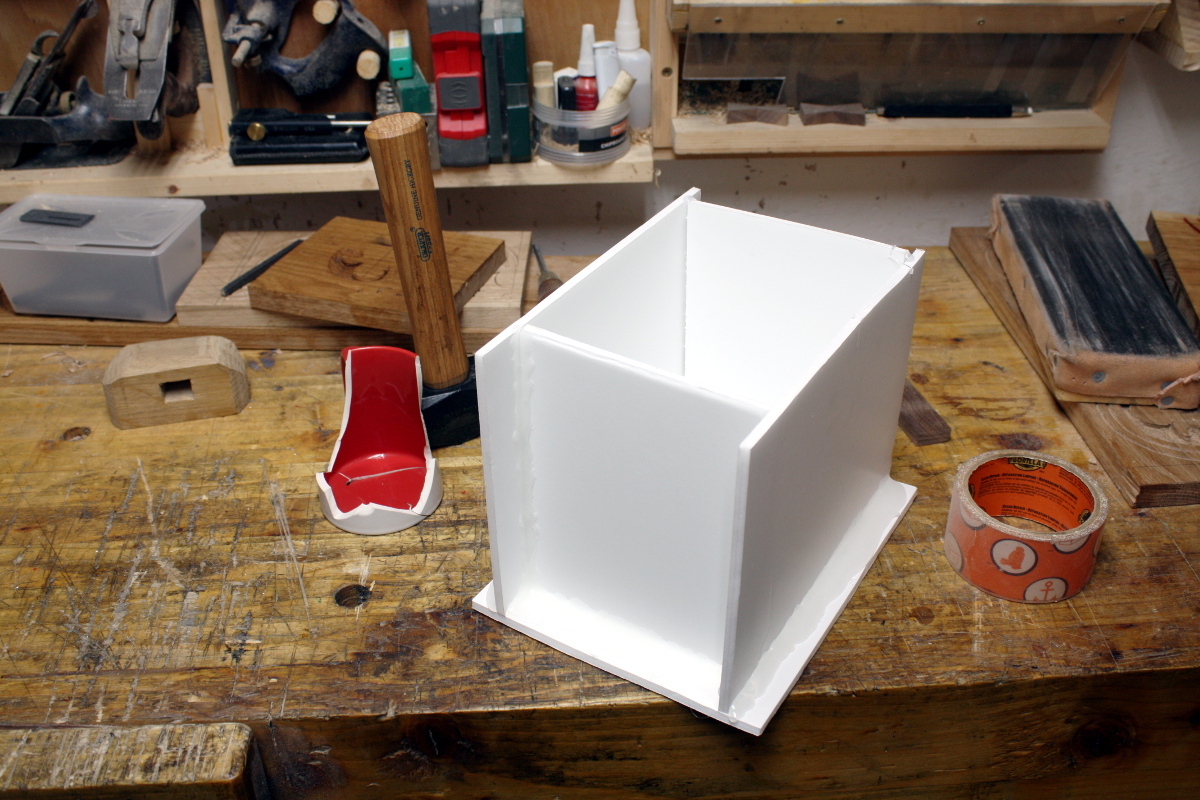

Foamcore mould, held together with packing tape and hotglue.

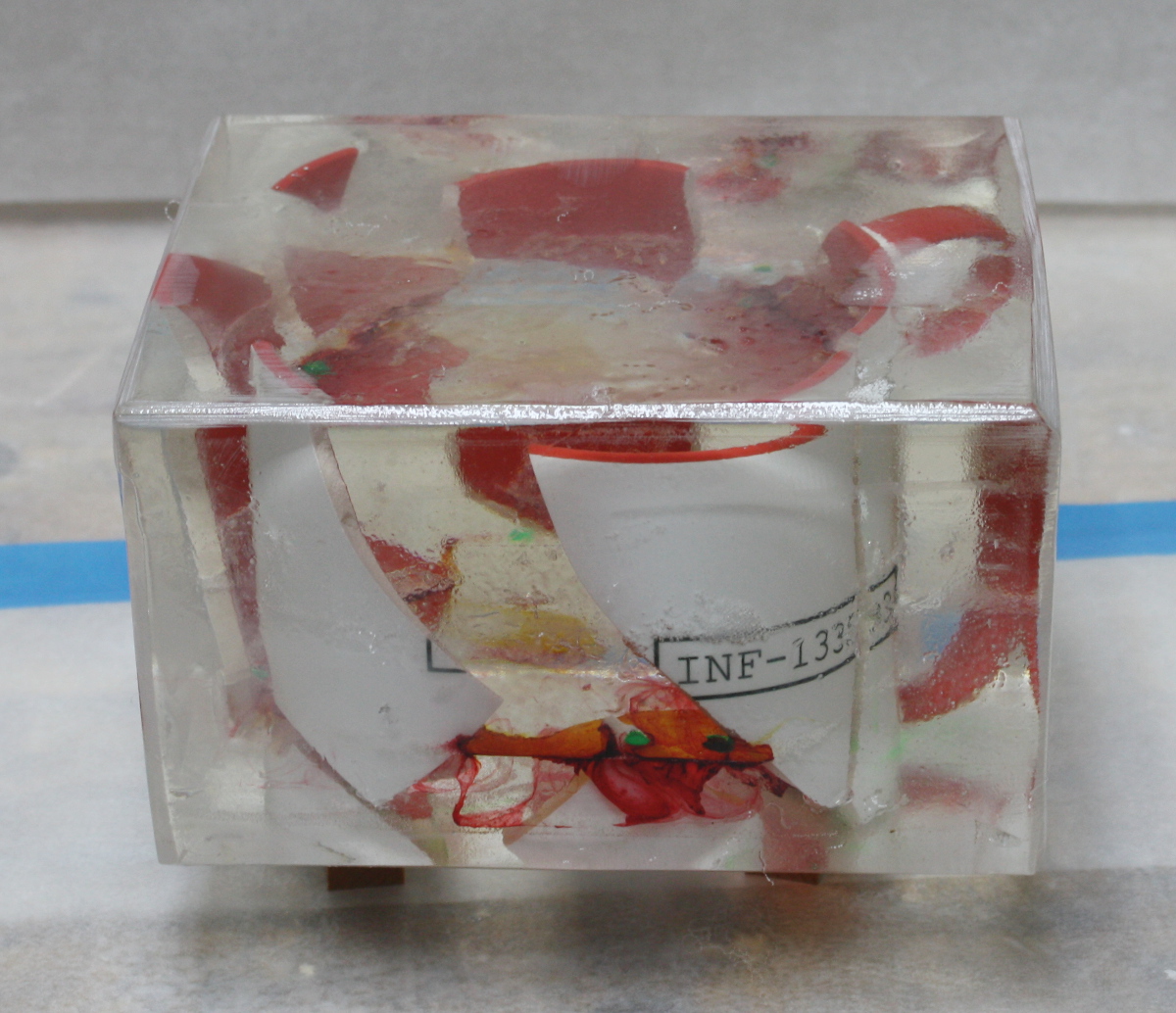

And now we start the first of several batches of resin…

Holding the pieces in mid-air so they’ll be in the right place when you pour the resin around it, and holding it in place while the resin sets, is a fiddly job.

Haven’t poured that much resin before, and the second-to-last layer had something of a thermal runaway and warped the foamcore.

Oh. Right. Foamcore does need mould release before pouring resin. Oh well. That wasn’t irritating and fiddly at all…

Still though, not horrific. I’ll cut off most of this with a knife and then…

Power tools time. Starting with 50 grit and working up to 150 grit.

Power sander is done here. And holy carp it was messy. It was like working inside a shook-up snowglobe.

This is going to need some major cleanup later on. But for now, onwards.

Now autosol applied by rag and then buffed with a power drill.

And finally some resin polish, again from Halfords.

And then I tried spraying with clear lacquer…

But it didn’t go so well, it left the surface cloudy even after fully drying and buffing. So I went back to the autosol and then the resin polish again and left it at that.

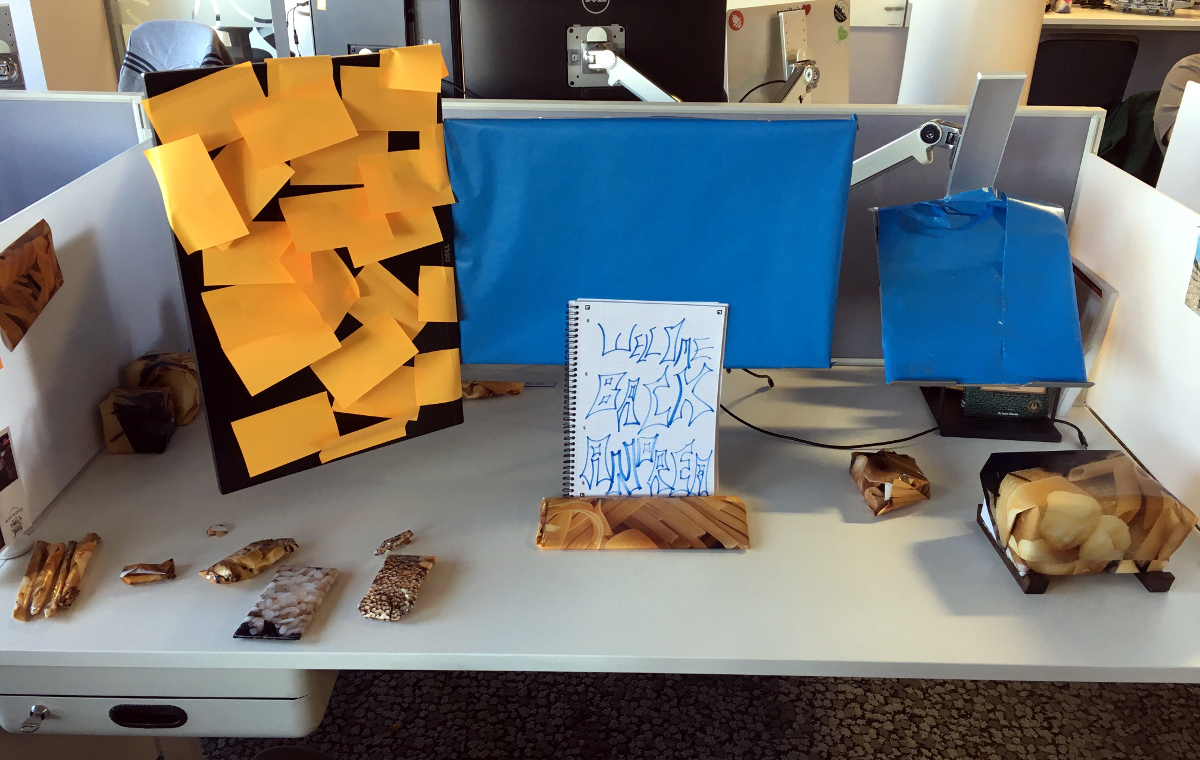

Then I knocked up a very very rough stand out of some walnut and felt and stuck it in my backpack and took it into work…

Not bad, but it’s missing something… oh, right, he’s returning on April 1. So…

That seems about right.

We did enter his mug into a Sustainability competition at work on the grounds that it will far outlast a single-use cardboard mug for the coffee machine but for some reason we didn’t win. Harumph.

I agree that it is entirely his fault.