So the walnut panel glueup went as well as I had hoped. The clamps did deform slightly – I need to do that trick of Paul Sellers and stuff them with wood – but the panel came together reasonably well.

There’s a step in the middle where one of the boards bowed though, of just over a mm, so there was some flattening to do before worrying about the surface much.

Ugly. Cross-grain planing required, so out with the #05…

At least it’s easy to see where I’m planing…

That proto-knot there in the back caused some issues with tearout that I’ll have to fix later. But the board is flat to the touch now and was smooth again after a few minutes with the #04 1/2

The chalk’s highlighting areas where even the cabinet scraper wasn’t handing the tear-out because actual lumps had been taken out during the cross-grain flattening. There may be epoxy filling required there, or putting in some inlay to hide it or something.

Also, the sides will be slanted, the shape of the desk is trapezoidal, not rectangular because the sides of the shelves splay outwards (and by the same amount as the sides angle back towards the wall by random chance). I haven’t made the cut yet because I have more boards to prep, and while the board is kicking about on the floor of the shed, that extra material is protecting what will become the edge of the desk.

Incidentally, as the desk is only 17″ off the floor and is for a six-year-old and so forth, I’m not too fussed about the underside…

So the scrub plane was used to get rid of that step on this side, and I didn’t really bother taking down the scallops afterwards. I mean, I gave it a few swipes with the #05 so it’s not “textured”, but I won’t be smoothing it with the #04 or scrapers and I might seal that knot but that’s about it for this side.

Mind you, despite this lack of worry, I’m still miffed at a certain phillips screwdriver…

Yeah, that smug looking git right there in the middle. I was putting away the #04 1/2 and the vibration of seating that back home in the till shook it off the magbar and…

Lousy git of a thing. Well, there’s another site that’ll need inlay…

At this point I fixed something small that’s been bugging me for a while. The LED lights I put up in the shed work well, but I hooked them up temporarily while I waited to get the shed properly wired with sockets and such, and I still haven’t gotten to that so all three of them are running into a single cable that plugs into the extension cable that has been running power to the shed as a temporary measure for over two years now…

I mean, for a day or three that’s… well, okay but not great even with cable clips giving the cable some strain relief, but it’s been up for ages because I was busy, so enough already…

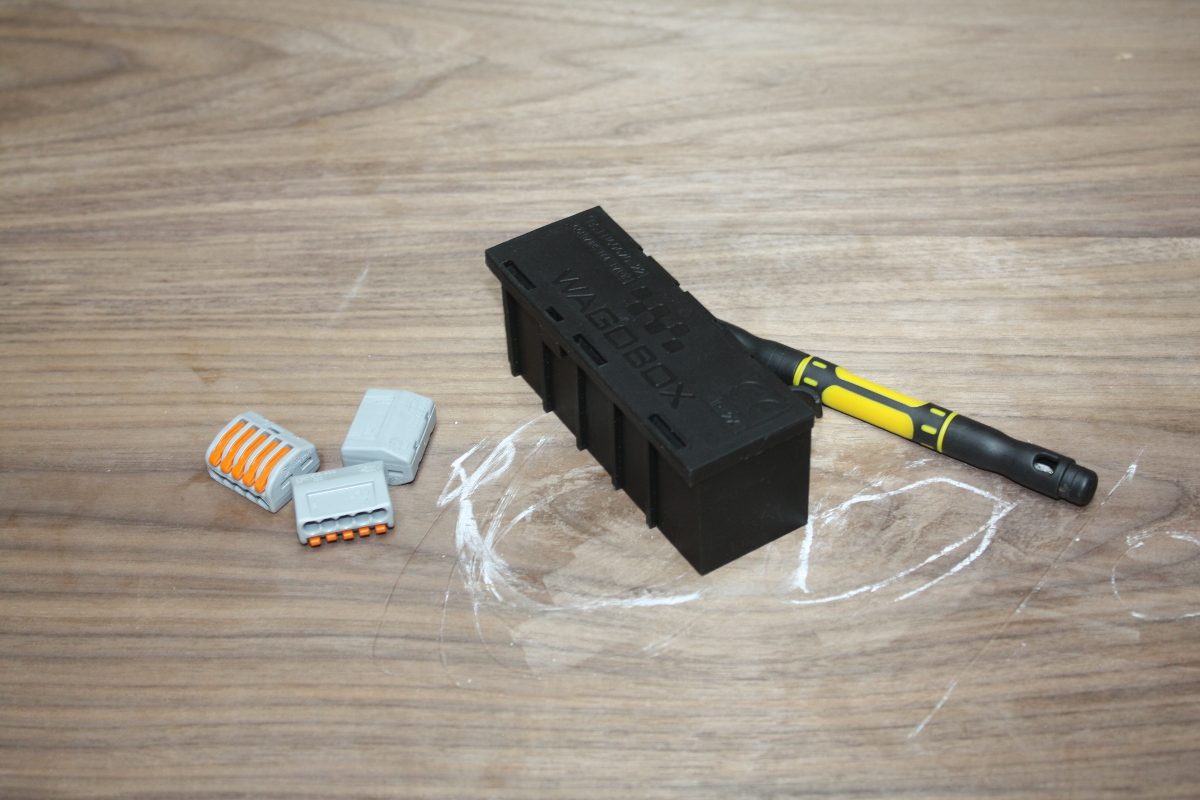

Those are wago terminals and a wagobox to house them. I’d never even heard of these until I saw Big Clive’s video on them

I’m so used to terminal blocks that they seemed like overly expensive gimmicky things to me at first, but after the first time you use them, holy crap they’re great. Those are the reusable version (there’s a permanent version that you can technically reuse but nobody does) because I still want to do this right, but this is so much better than the temporary lash-up I had waiting to fall on my head if I kicked the line by accident and run 240V across my scalp. Which, y’know, is suboptimal. So I undid the terminal block and linked everything up with the wago blocks…

And stuffed those into the wagobox and mounted it…

And reran the cable clips and put the cables into the wagobox’s strain relief glands and sealed it all up.

Nice and neat(er) and all working again and no exposed points where you could accidentally grab or poke something and there’s a lot more strain relief on that black mains cable. Much better.

Back to work after the long weekend and a few days’ holidays tomorrow so I’m expecting a long day or two in the office, and then when I get shed time again it’ll be on to the other shelves. Being poplar, they should be both easier working and less pretty than the walnut. Not sure if they have a date with the thicknesser, but if so that’ll be delayed until a Saturday afternoon and I’m not sure how the sides would be done as there’s no way I can run those through the thicknesser inside the shed, there’s just no room; and it’s way too loud to run outside on the decking. They may need to be done by hand with the scrub plane, but at least they’re poplar so it’ll be lighter work.

Tags: electrics, hand tools, planes, shed, wago, walnut, Woodworking, Workshop