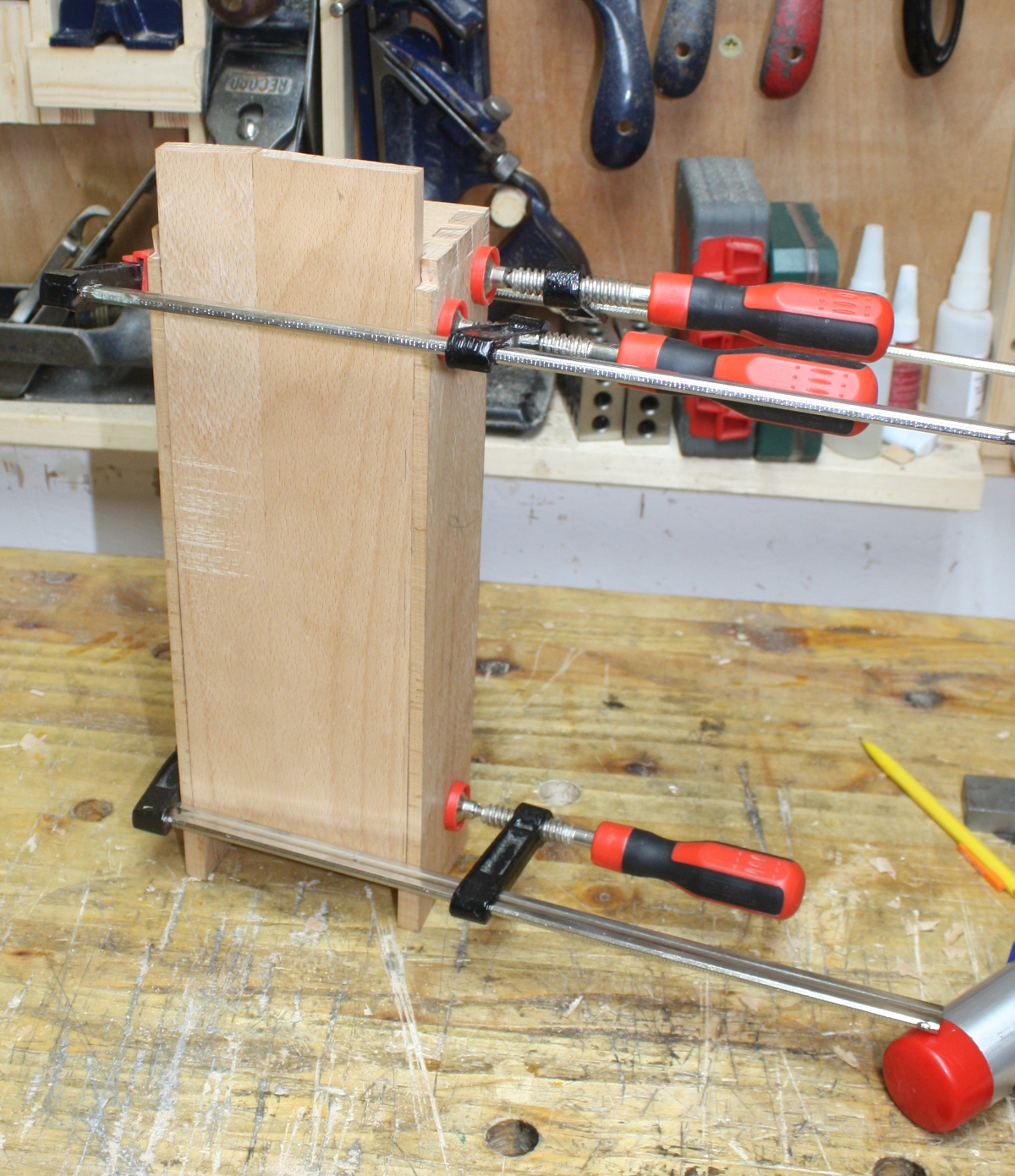

So the repair job from yesterday went reasonably well. There’s a lot of excess CA to clean up, that took a few minutes for the face side, and a bit longer for inside the rebate itself. Lots of chisel work, some scraping, and dug out the Record 311 with the nose off and the 077 to fettle things and clean up the rabbet to get a square inside corner. Then cut the rabbet on the other side wall, which took far less time and had no drama to it, then cut the rebate in the top piece and then test fitted it and realised my mistake – by cutting the rebate in the top, I’d introduced a gap where I thought there wouldn’t be one. How I didn’t see that coming I don’t know. So I fudged, and sawed off the rebated part, right through the dovetail joint, and the back panel will do the filling.

And then, fettling. Assemble everything, stare at it, notice one wall is not parallel to the other, figure out which of the three cross-pieces is at fault, knock it all apart, shorten the offending piece (of course it’s the one with the dovetails, so cut them 2mm deeper), reassemble everything and repeat seven or eight times, sneaking up on square gradually.

Once I was finally happy with that, I took the panel for the back, squared an edge and an end (didn’t matter if it spelched out on the far side from the squared edge because that’s coming off anyway), and fitted it in place and mark off the far side against the other side wall, and then saw outside that line and plane down to it, and test fit.

And then do the fettling cycle two or three more times, taking a shaving here and a shaving there. And eventually…

Not terrible. Some gaps here and there, so it’s not perfect, but could be a lot worse. Still have to cut the panel to length, that’s marked out for, but first check it over.

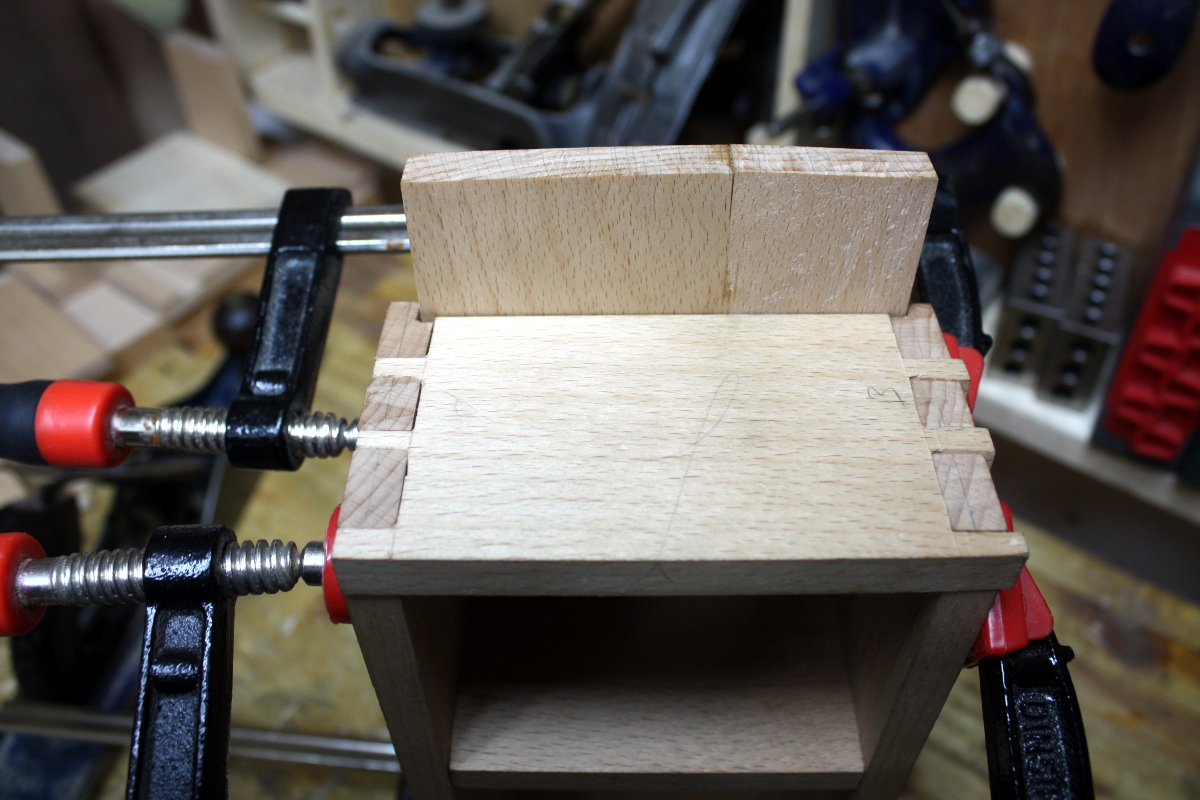

Dovetails close up (mostly). Might need to plane that top piece a bit more yet at the back to let the panel sit better on the left there. And then check for square…

That’s all grand to within 0.2mm or so, which I’m okayish with for now (hey, I’ve never worked in beech before, I’m getting used to it, okay? Plus, that’s rather thin stock, it’s just under a half-inch there).

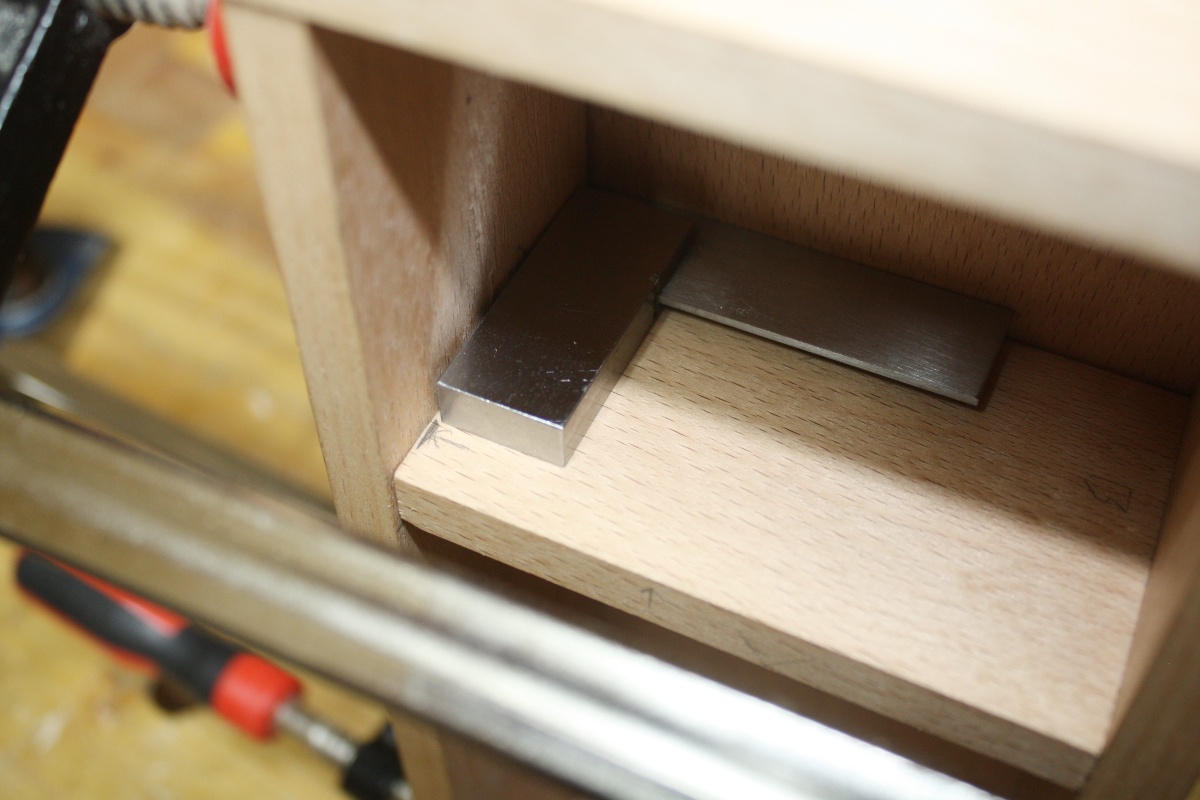

One last joint that I’m not happy with…

Need to knock that apart and give that marked spot a swipe with the block plane, let the front of the side panel close up there. Hm. But that wouldn’t explain those gaps in the middle and rear dovetails on that side and the front dovetail is tight up – maybe I need to pare that dovetail just a hair deeper instead. Or it could be both. The joy of fettling…

…oh, and I need to fit the door as well at some point. And I got two bandsaw belts in the post today that I need to check – they were 120XL037s instead of 124XL037s but they might be close enough to do for a few days until the proper size ones arrive…

Tags: bandsaw, beech, dovetails, fettling, hand tools, planes, Woodworking