So it’s a bank holiday weekend and I was looking forward to lots of time in the shed, but on friday a nice lady held me down and shoved a screwdriver and a pair of pliers in my mouth so I wasn’t really up to much woodworking on the Saturday, but at least the extraction didn’t cause too much pain after the fact so today I decided to hit the shed and get on with some stuff, and I thought I’d start with some resawing.

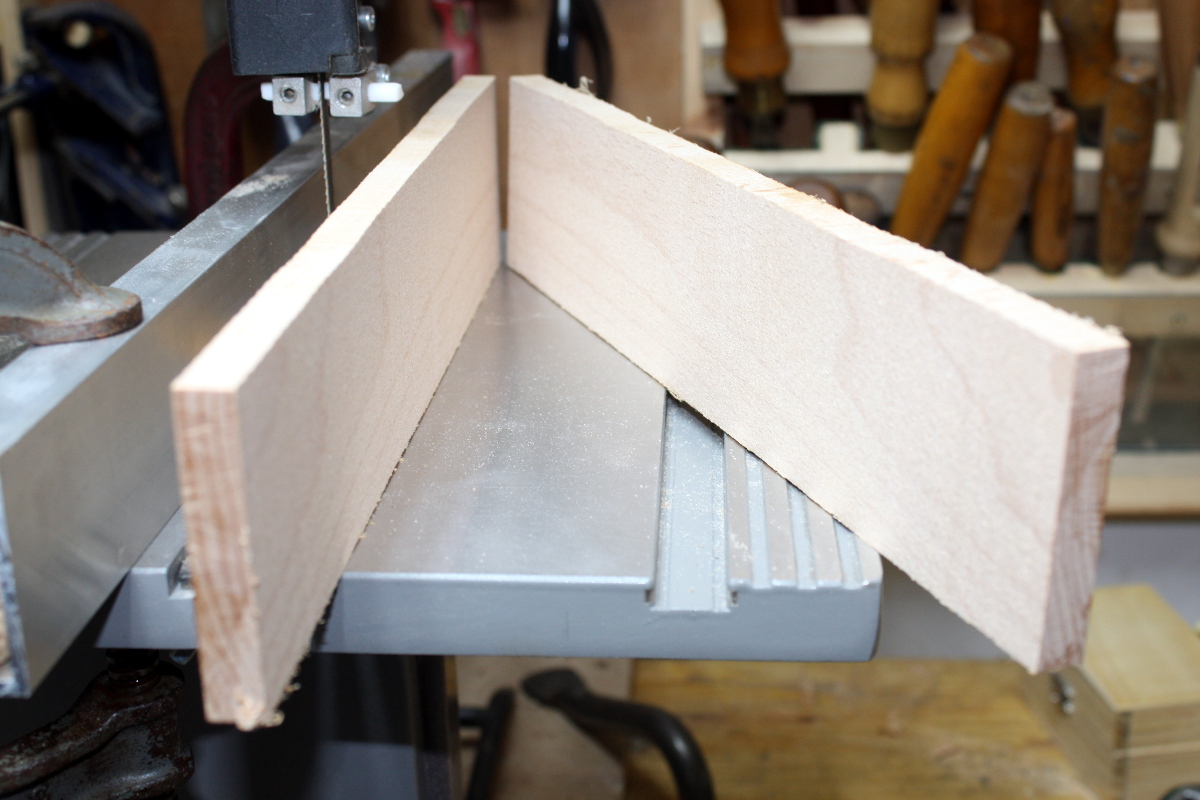

The fence they ship the Titan bandsaw with is ridiculously awful, so this is what I normally use – just a length of extruded aluminum that normally serves as a straightedge when planing. I must see about getting a wider box section for this job though, the underside of the table has ribs so it’s not so easy to find a flat spot to get the clamps on without tipping the fence over when you clamp. But after some faffing about I got it all set and started to feed in the beech, and getting pretty good results (This is 75mm wide material, the upper limit for the machine).

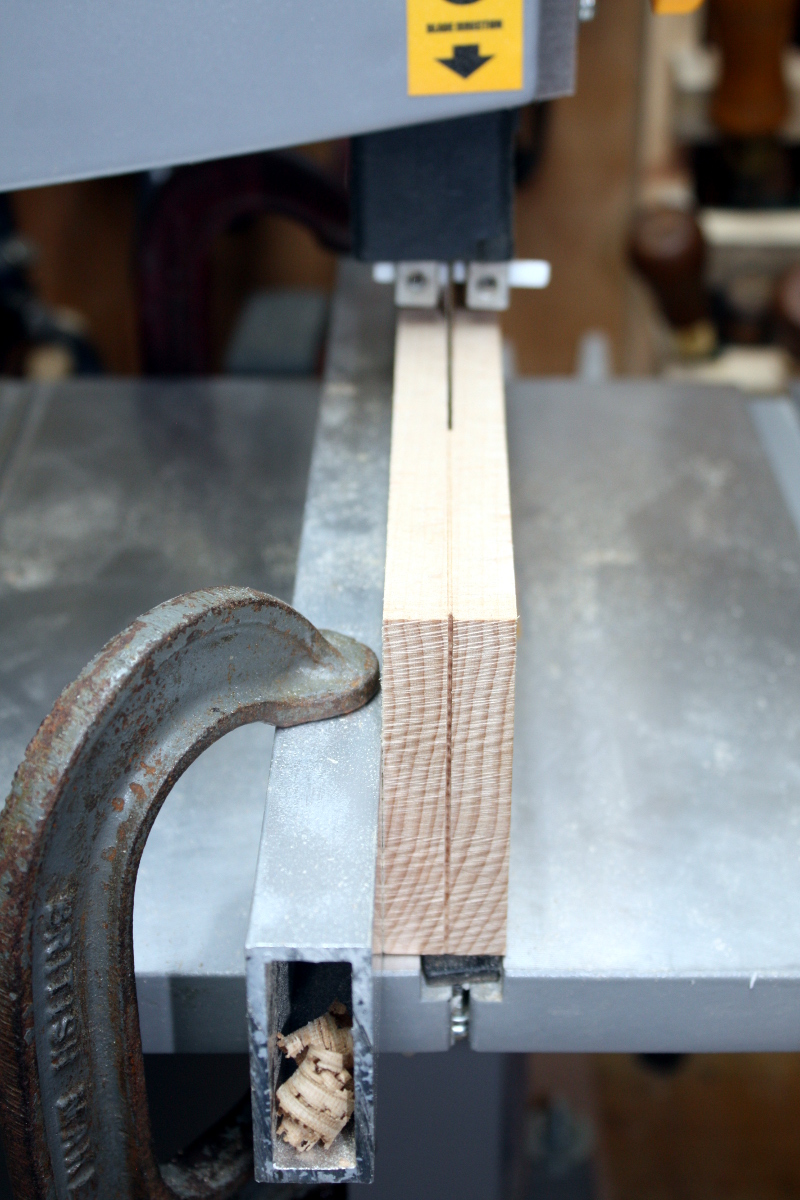

Nice straight clean cuts, minimal saw fuzz, no wandering or blade drift, I was happy with that. Then on the last board…

Just literally ground to a halt mid-cut. Motor’s still spinning, but the blade’s not moving. I was sure I’d overheated the little motor or something so I turned everything off and let it sit for a half-hour and then tried again, but to the same result – the blade would move allright, but the minute it hit the wood, it stalled out and stopped while the motor kept spinning. So I opened up the lower box and sure enough…

Note, the belt hadn’t snapped, I cut it out of the bandsaw to save time, the problem is that the teeth are all stripped off the inside of the belt (note the melted fuzz on the remaining third of the teeth, and there were a lot of completely stripped off teeth on the bottom of the lower bandsaw cabinet). It’s a 124XL037 belt in case this ever happens to you, and like the bearings, these belts are industrial lego. If you don’t need them fast, you can get a box of ten from aliexpress for $16; if you need them tomorrow, Radionics will ship you two for the same price in a day or so. So I’ll be sorted before the end of the week, but it’s still a bit of a pain in the fundament.

Still though, got most of the boards done.

That bottom one is 100mm wide, it wasn’t getting resawn, it’s to be thicknessed. And the remaining board I was mostly through so I finished resawing it by hand.

Yeah, still not my favorite part of this hobby. But beech turns out to be nice to saw.

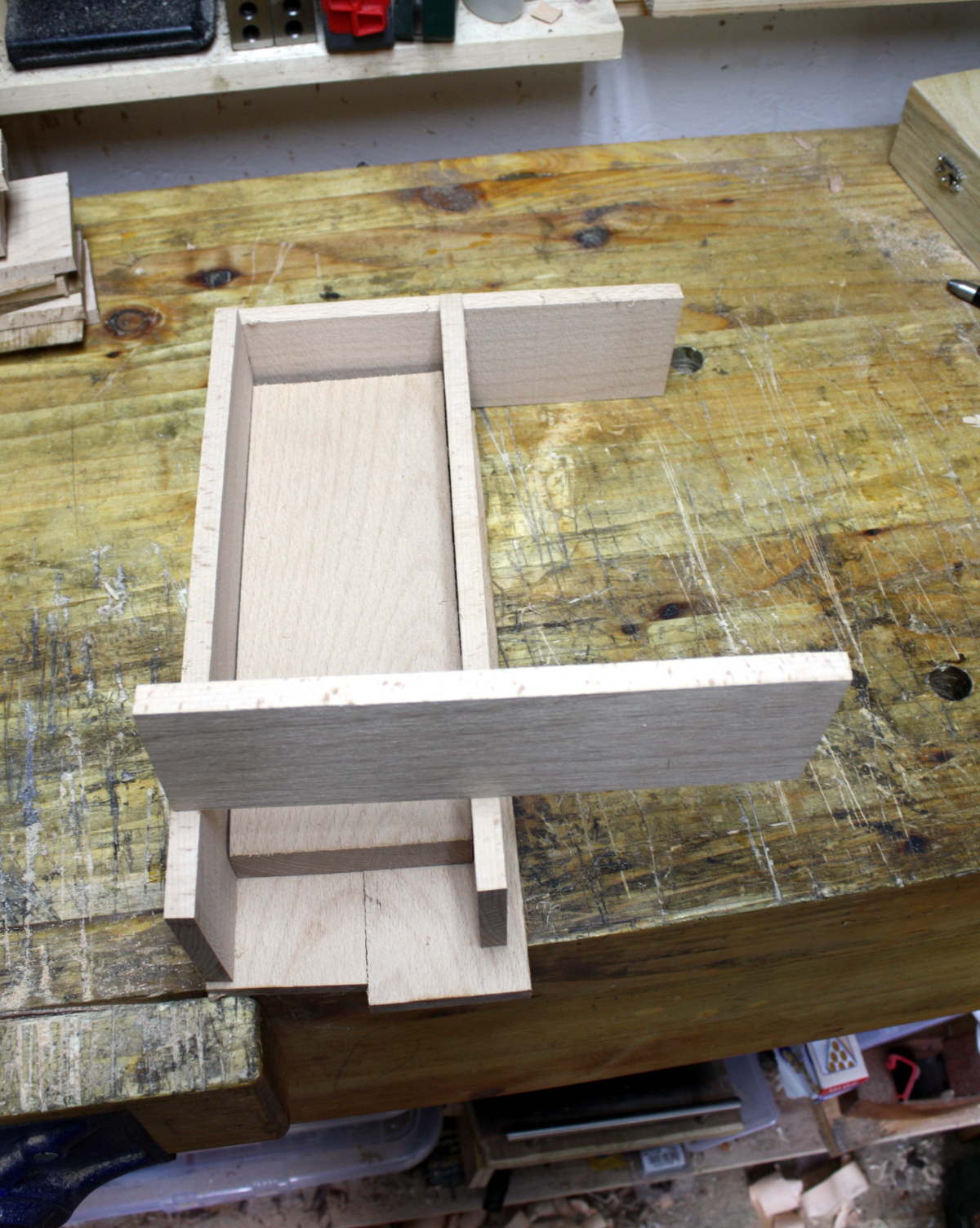

Then laid out the parts for the next project…

Bit of a glue-up panel for the back…

That’ll be ready tomorrow and then I can continue planing the parts. Then the outside frame gets dovetailed, the inner shelf and bottom get housing joints, I’ll rebate the panel into the frame at the back and thickness the door and that’ll be that.

Yeah, so only another six months 😀

And then maybe some stringing for decoration… or some carving… 😀

I also got some walnut pieces rough-cut from an offcut from the sidecar cot to be used in the experimental box. I’m just not looking forward to resawing that to a usable thickness and I hate thicknessing walnut by scrub plane, it feels like such a waste. Oh well. Frame saw time maybe.

Tags: bandsaw, beech, resawing, tools, Woodworking

The Grizzly bandsaw fence is pretty good if you want a working replacement fence. My Ricon bandsaw also had a crappy fence. I replaced it with the Grizzly several years ago and it has worked well.

ken

It’s not a bad idea Ken but getting Grizzly hardware on this side of the pond is a bit difficult. I usually don’t use a fence for anything but resawing so it’s not a huge deal to just use the shedmade one.

“the underside of the table has ribs so it’s not so easy to find a flat spot to get the clamps on without tipping the fence over when you clamp”

What about using a piece of wood under the table to bridge the ribs.

Ad-hoc solution but, if you can drill holes in the table, you could screw the board making things easier to use. Or using glue?

Sylvain

on instagram:

“I had a cheapo #4 that I was using but the casting was digging into the edge of my hand and I was bleeding on the work which wasn’t helping the finish any, so I got another Record #04 to convert to a scrub plane. ”

I have followed Paul Sellers example and rounded with a file every edge on my (chinese?) plane (except the cutting edge ;D and the mouth). I have also rasped the handle were it was hurting.

Shooters use to custom handles, don’t they?

https://www.youtube.com/watch?v=RYyV6IUpsYk

see at 13’12”, 41’43” and 52’01”

Sylvain

It’s not a bad idea, but you would have to drill the table which I didn’t want to do; also a 3″x2″ box section of extruded alu would let me move the clamps between the ribs easily and give the fence greater stability so it’s a win-win (3×2 instead of 3×3 because with 3×2 you get either a 3″ or a 2″ fence depending on your needs – if you need a 1″ fence, something’s very odd but the straight-edge section I have already could do that). Also, the front side of the table is relatively uncomplicated on the underside, but the back side has the pivoting gears and is a bit more finicky. If I just focussed on the last two inches or so before the edge it might work though…

I spent quite a while custom-building my own pistol grip alright Sylvain, it’s a familiar bit of work; but the problem with this plane is that it was digging into my hand even after I had filed it, the casting is so bad. And I couldn’t do much at all with a file to the adjustment knob and hardware, and if I ever forgot and curled my fingers around the grip fully, I got reminded on the next stroke by that hardware removing all the skin off my knuckles.

It just really was a terrible, terrible cheap piece of dross; which in 1930 would have meant a plane Lie Nielsen would have been happy to sell but which in the last two decades means something whose most positive virtue is that it won’t immediately kill the user…